Side bow conveyor chain with inner and outer chain links

A technology of conveying chain and inner chain link, applied in the direction of conveyor, drag chain, hanging chain, etc., can solve problems such as incompatibility, and achieve the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

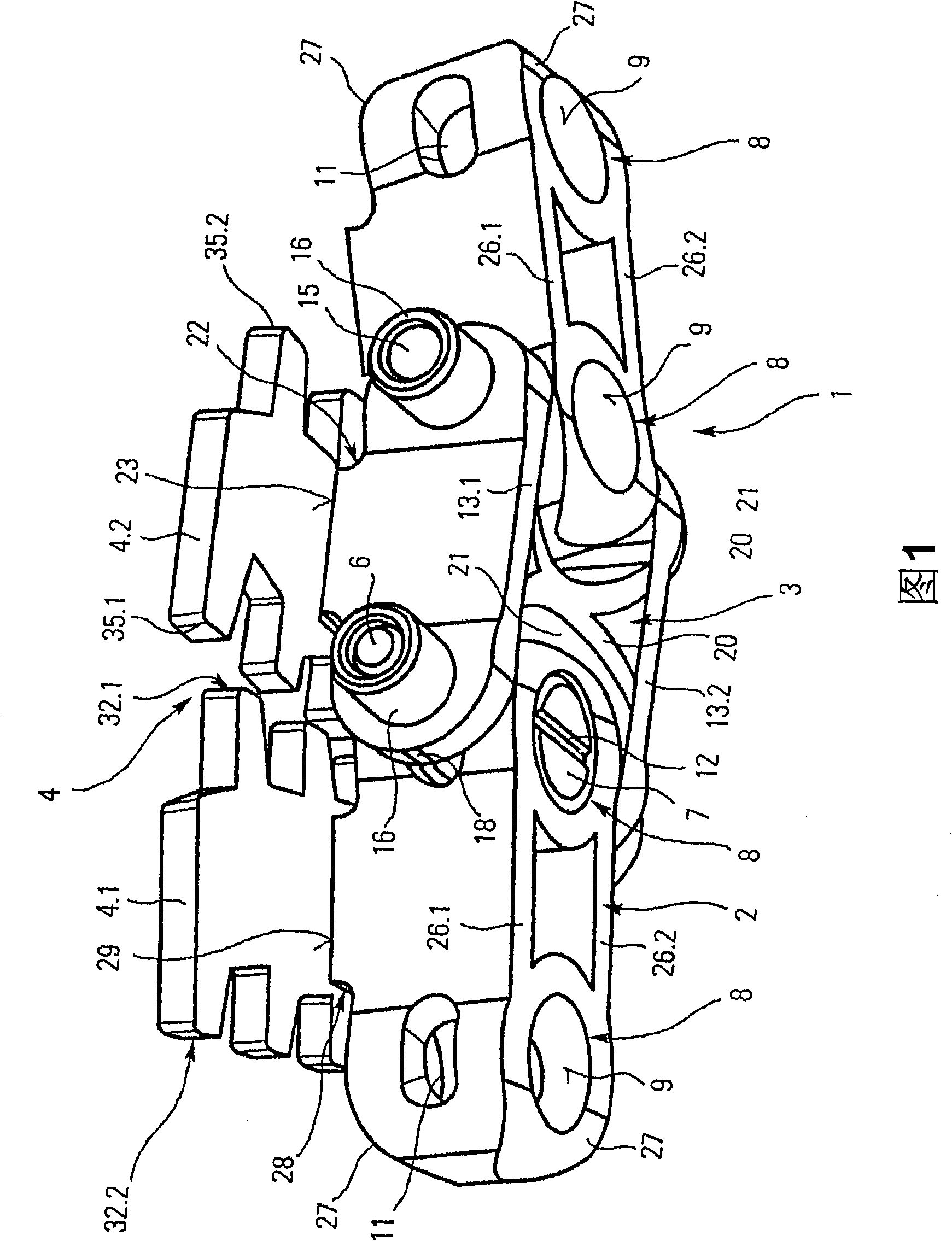

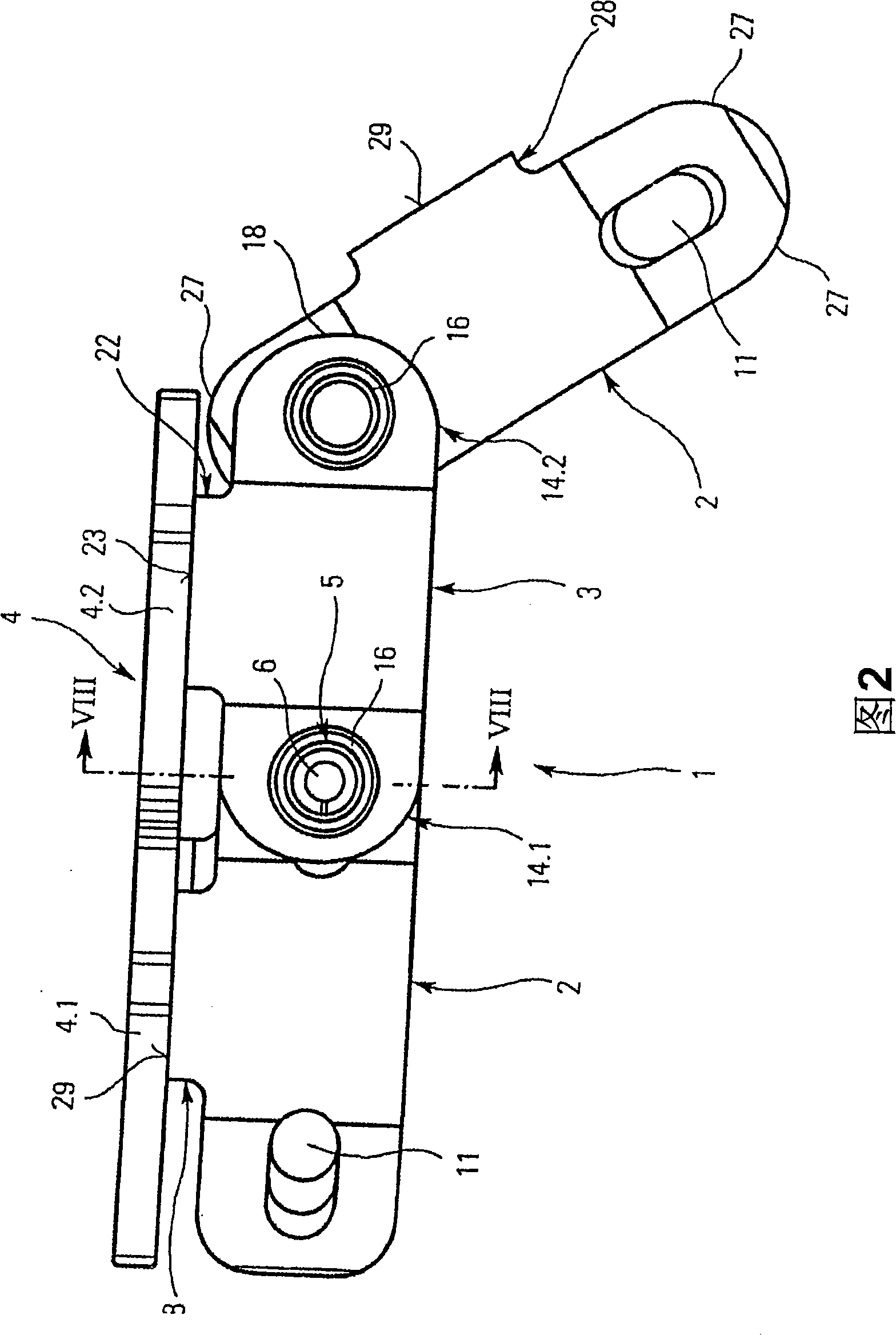

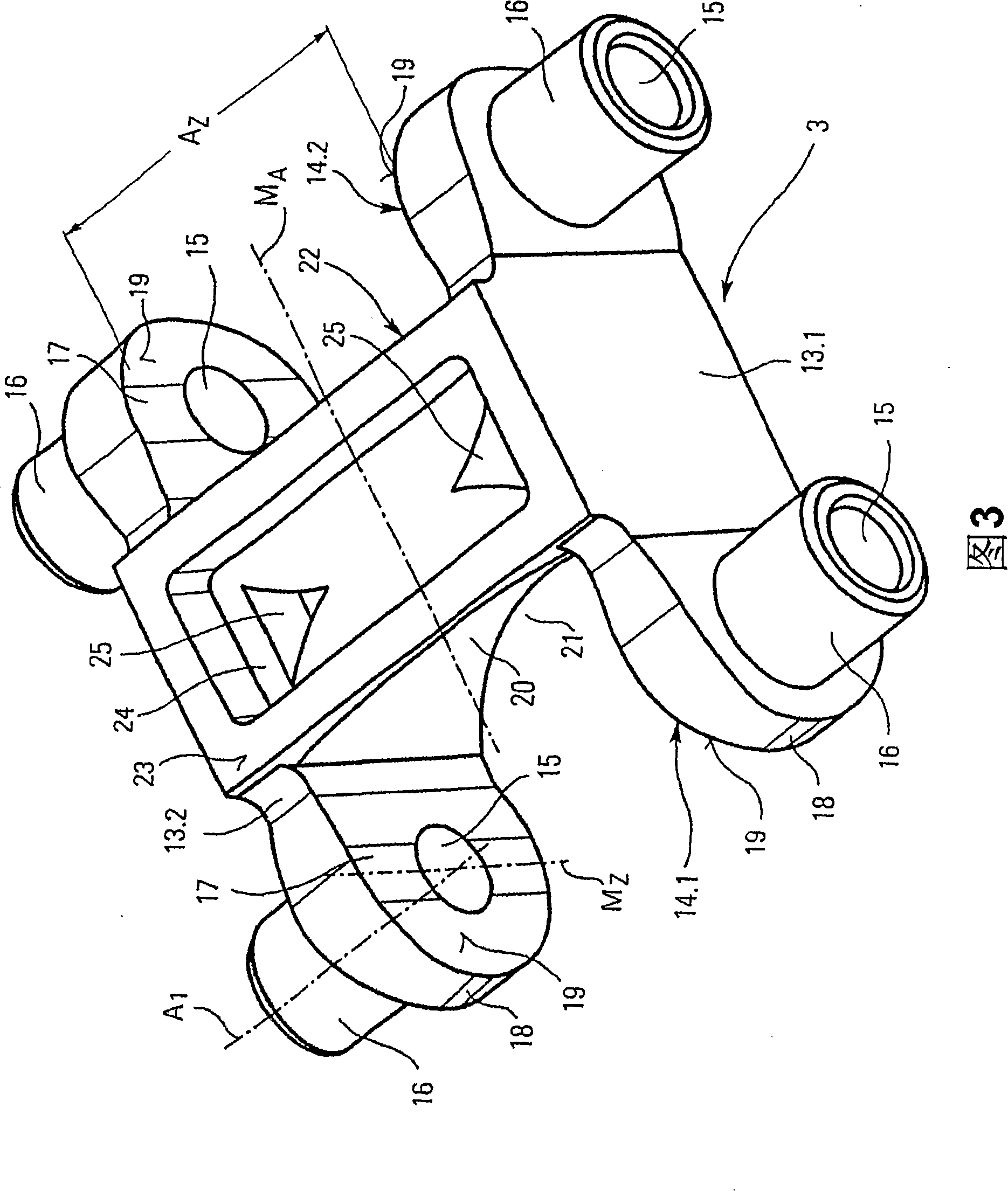

[0044] Referring to FIGS. 1 to 12 , a first embodiment of a side bending conveyor chain 1 (hereinafter referred to as: chain) according to the present invention will be described in detail. The chain 1 comprises inner links 2 and outer links 3 arranged in alternating succession, and a plate belt 4 arranged on the links 2 and 3 and defined by individual support plates 4.1 and 4.2. The connection between the inner chain link 2 and the outer chain link 3 is formed by a chain hinge 5, wherein the chain hinge 5 is arranged to be able to surround ( Figure 8 middle horizontal) first axis A 1 and around ( Figure 8 vertical) second axis A 2 pivot. Each chain hinge 5 comprises a pivot bolt 6 and a cylindrical pivot pin 7 , as well as a receiving sleeve 8 which is provided as an integral part of the inner chain link 2 and accommodates the pivot pin 7 and the pivot bolt 6 . The pivot pin 7 is arranged in a base hole 9 of the receiving sleeve 8 such that the pivot pin 7 can move arou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com