Annular U type diaphragm for hydraulic diaphragm pump

A hydraulic diaphragm pump, annular technology, applied in the direction of pumps, pump components, variable displacement pump components, etc., can solve the problems of diaphragm stress and stress changes, inconvenient installation and maintenance, excessive deflection and deformation, etc., and achieve the deflection and deformation volume. Large, convenient installation and maintenance, the effect of prolonging the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

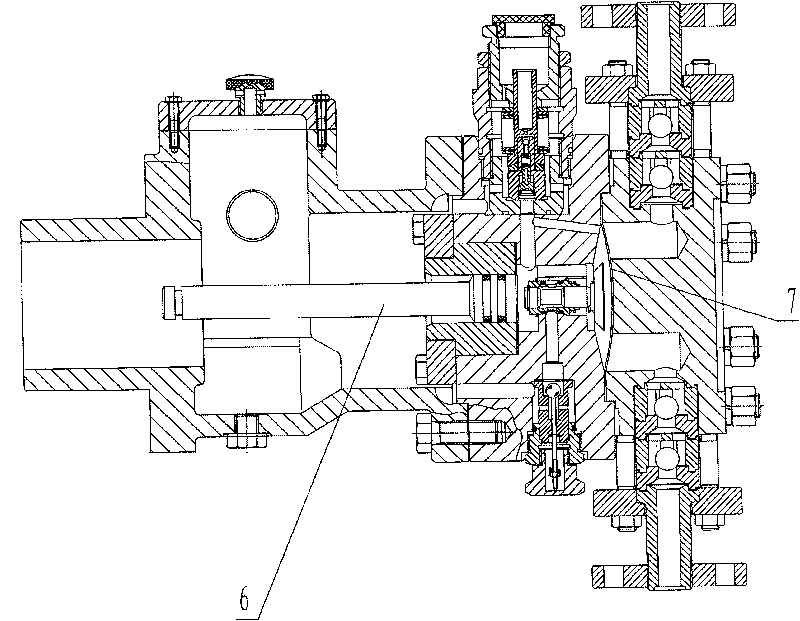

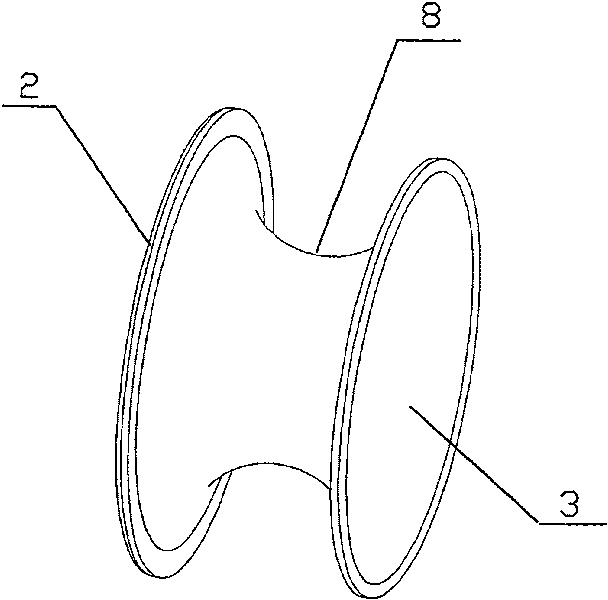

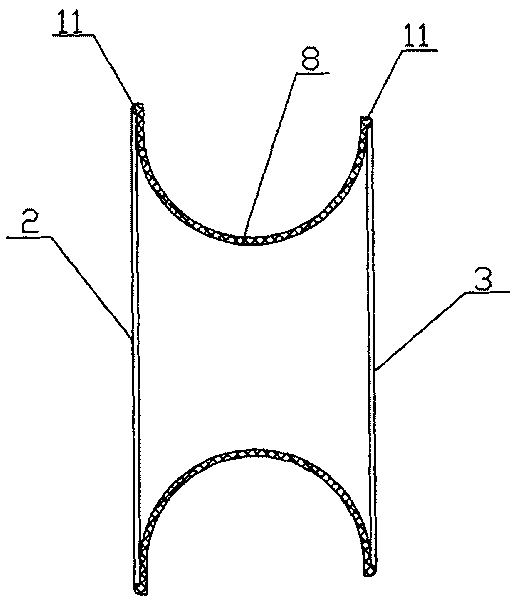

[0012] see Figure 2-4 : A kind of annular U-shaped diaphragm for a hydraulic diaphragm pump, the side wall of the annular U-shaped diaphragm is surrounded to form a hollow structure, the middle part of the annular side wall 8 is concave, and the two ends expand outwards to form a trumpet shape. The outer edge of the bell mouth 2 is liquid-tightly installed on the diaphragm chamber wall 4 of the hydraulic diaphragm pump. There is a distance between the outer edge of the bell mouth 3 at the other end and the diaphragm chamber wall 4, and the bell mouth 3 at the other end The diaphragm plate 1 that is liquid-tightly matched with it is installed on the top, and the diaphragm plate 1 cooperates with the annular U-shaped diaphragm to separate the diaphragm cavity of the hydraulic diaphragm pump into the inner part of the annular side wall 8 and the diaphragm plate 1. The oil chamber 9 and the medium chamber 10 located outside the annular side wall 8 and the diaphragm plate 1.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com