Transfer printing head of laser transfer printing apparatus

A technology of laser transfer printing and transfer head, which is applied in the field of transfer head, can solve the problems that the floating control method cannot be used, it is easily affected by electricity and magnetism, and it is difficult to realize, so as to shorten the interval between production cycles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

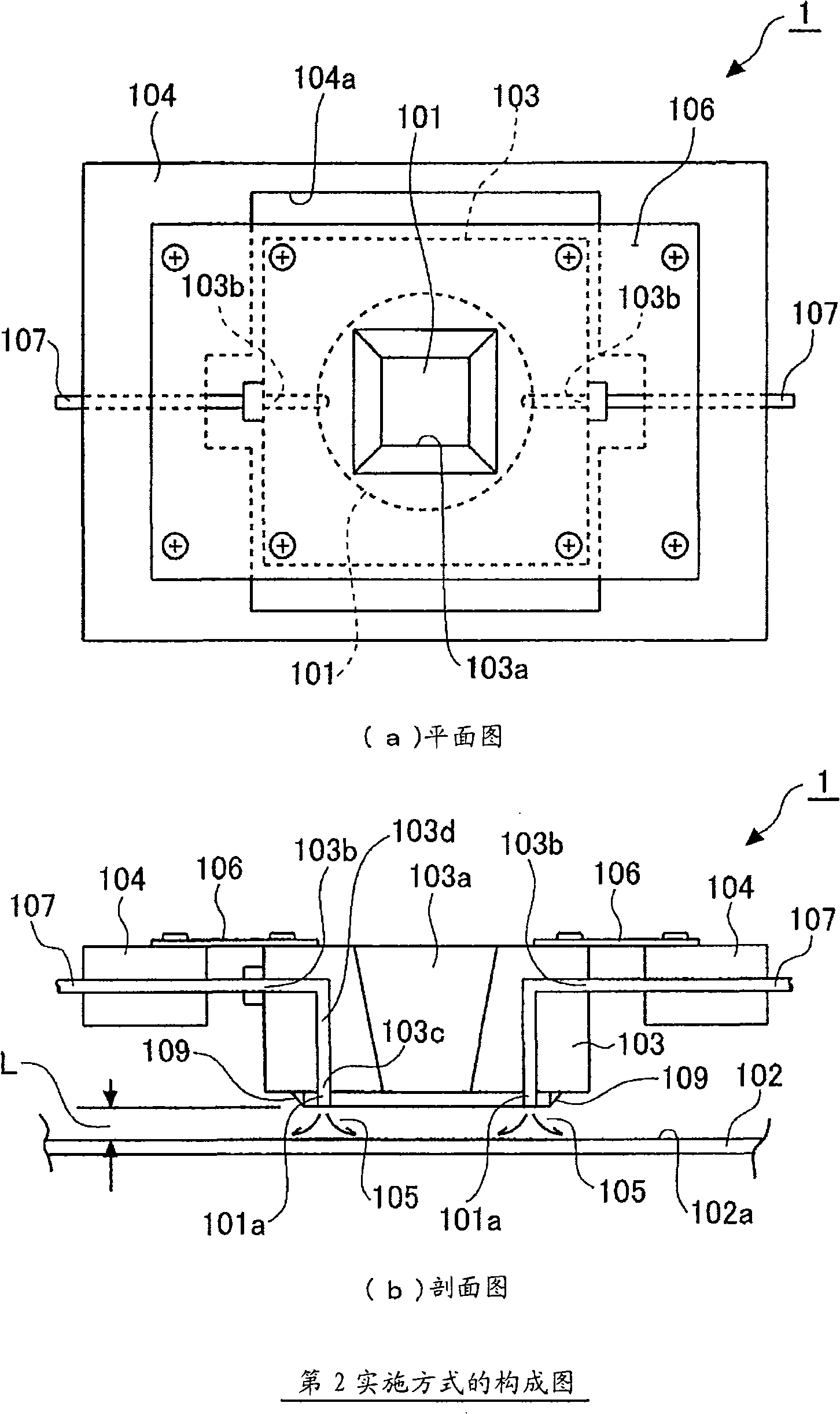

[0083] Next, preferred embodiments of the transfer head of the laser transfer apparatus according to the present invention will be described in detail with reference to the accompanying drawings.

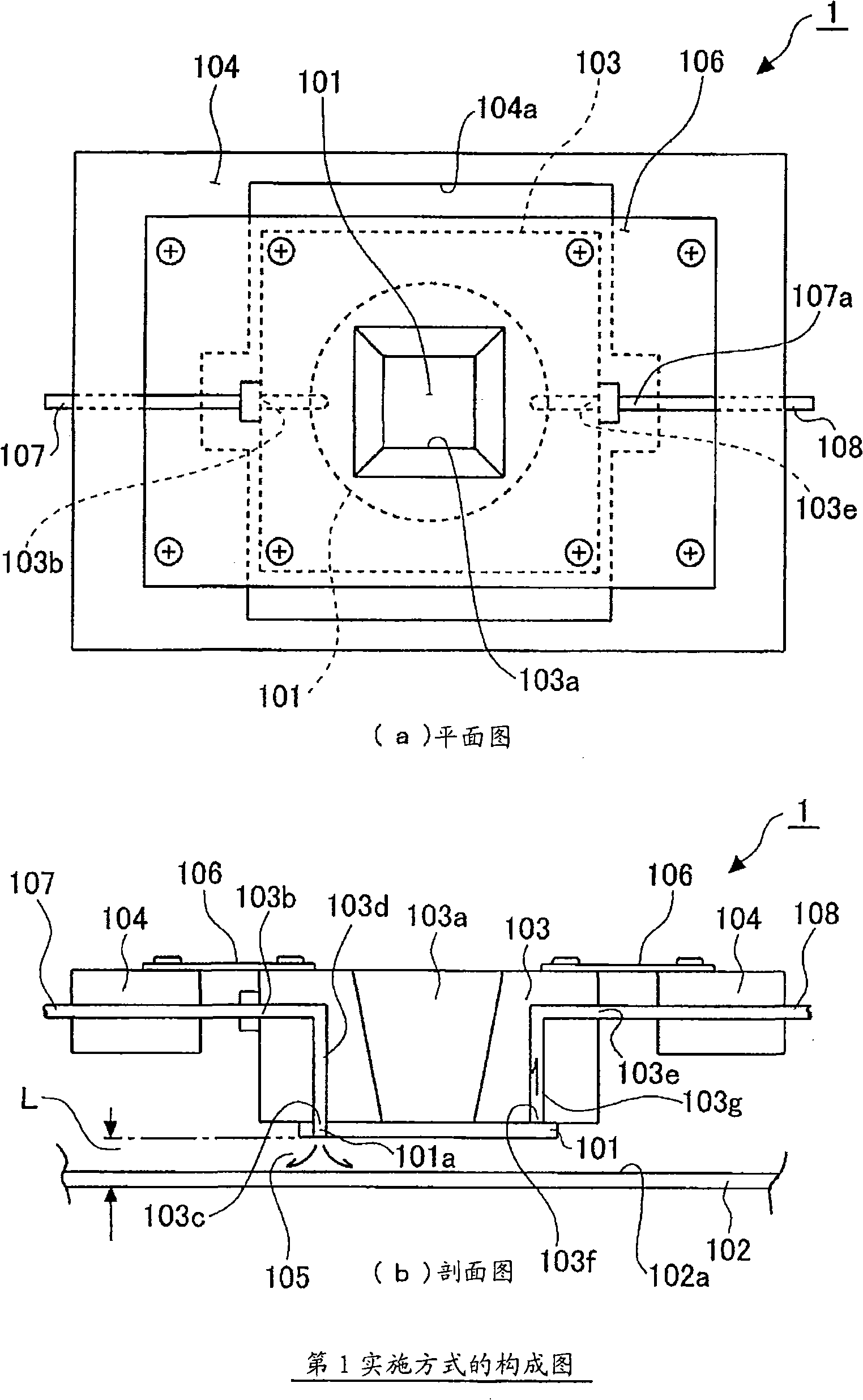

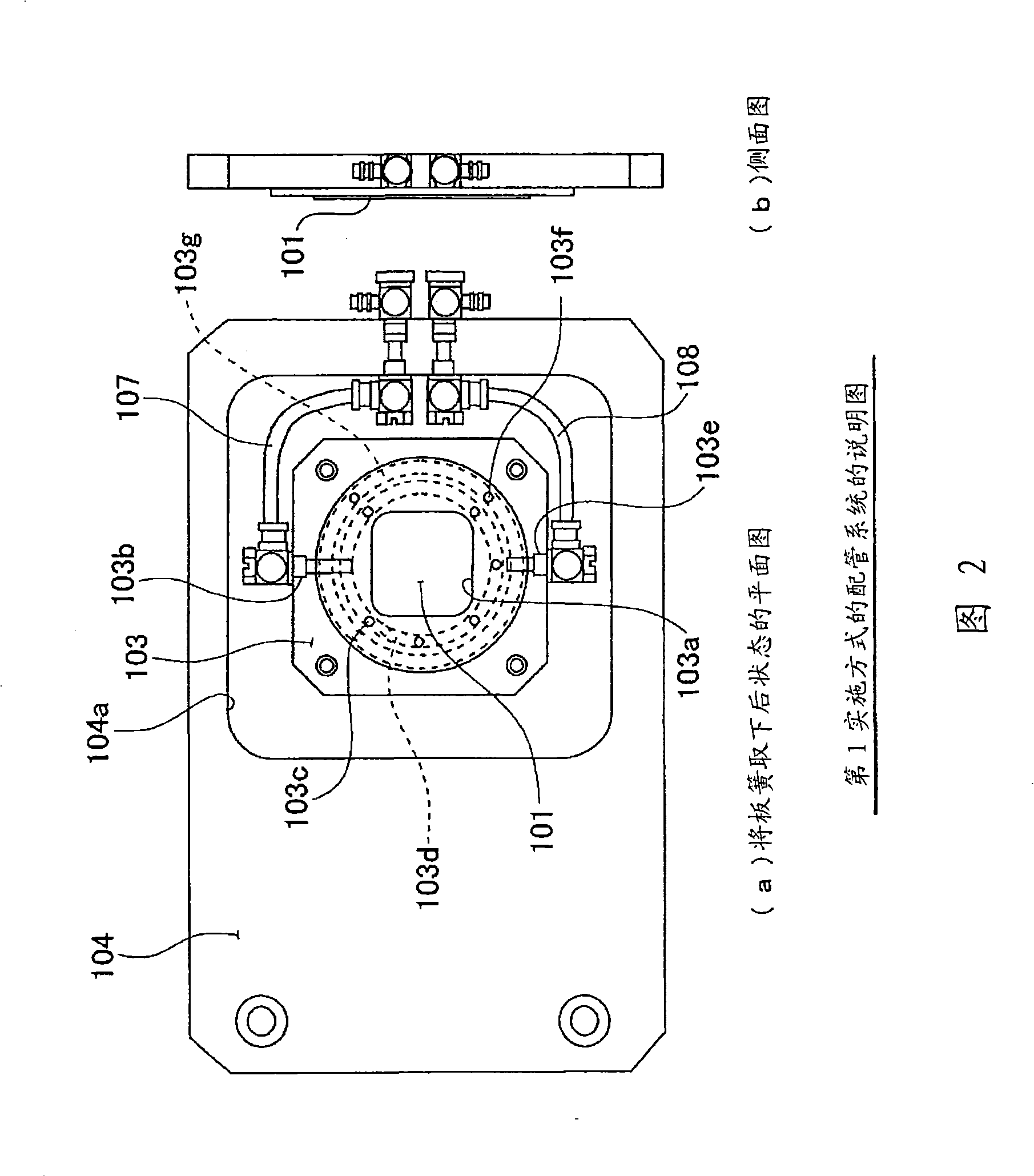

[0084] figure 1 Shown is a configuration diagram of the first embodiment of the transfer head of the laser transfer device of the present invention, wherein figure 1 (a) is a floor plan, figure 1 (b) is a sectional view.

[0085] As shown in the figure, the transfer head 1 of this laser transfer apparatus is used to support a transfer plate 101 in a state where the transfer plate 101 is placed on a plate-shaped small piece (for example, a plate-shaped small piece of quartz glass) having laser light transmittance. ) on the object surface (lower side in the figure) is covered with a transfer material (such as Al, Ni, Ta, W, Ti, Au, Ag, Cu, Cr, etc.) thin film, the state is to make the transfer object The transfer material film and the transfer surface 102a face each other with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com