Method and apparatus for flexibly starting high voltage motor

A soft start and high voltage technology, which is applied in the direction of motor generator/starter, single multi-phase induction motor starter, continuously variable inductor/transformer, etc., can solve the problem of limited adjustment range and large harmonic pollution , large loss and other problems, to achieve the effect of long service life, good energy saving effect and strong overload capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

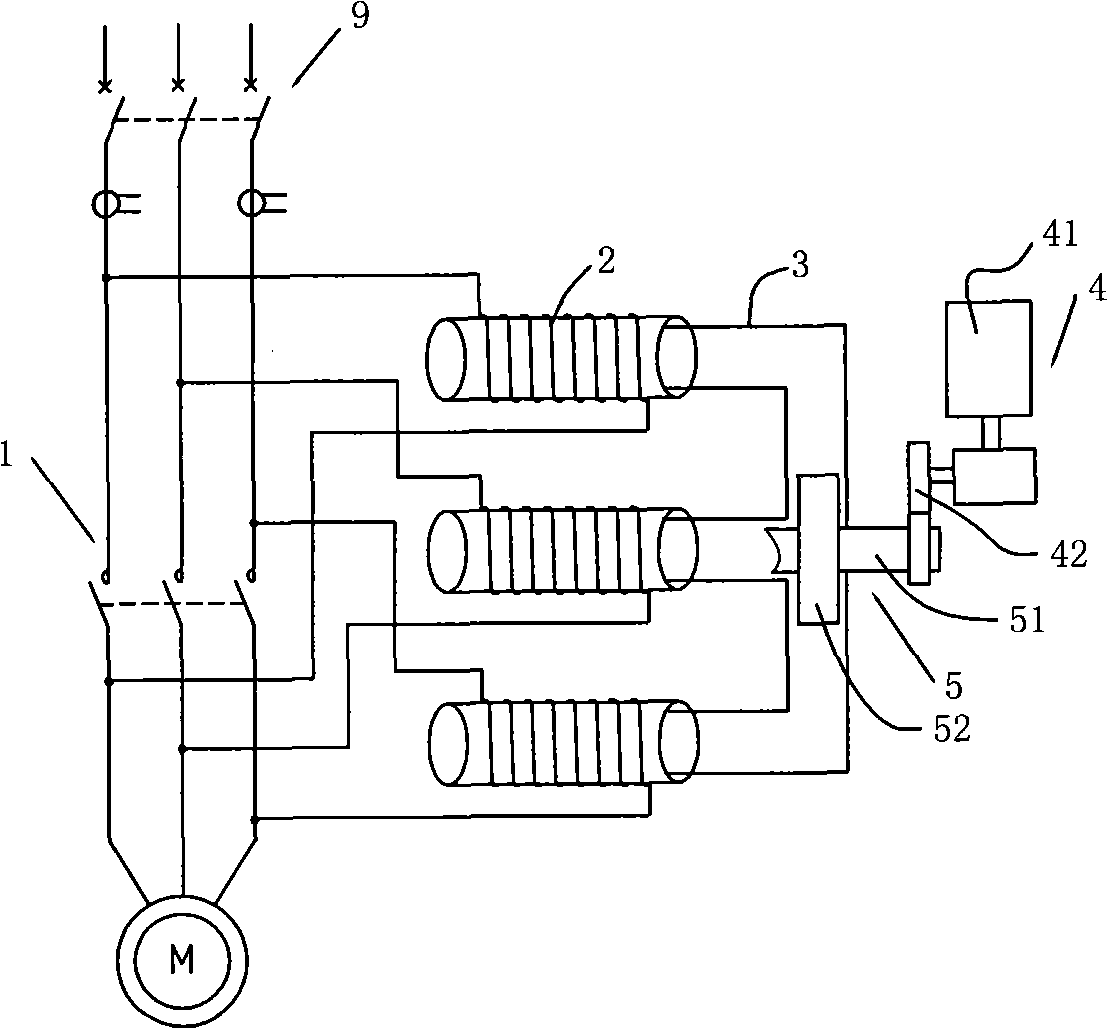

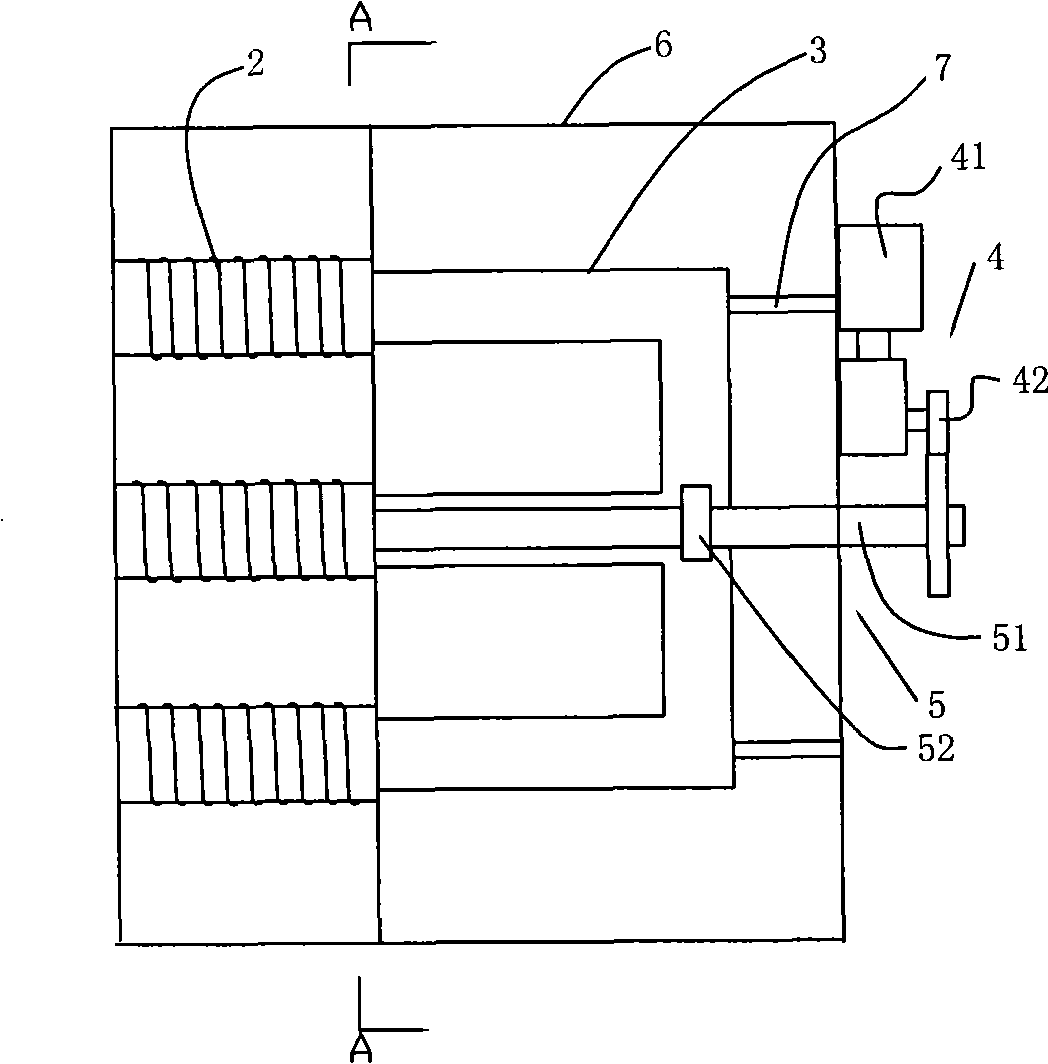

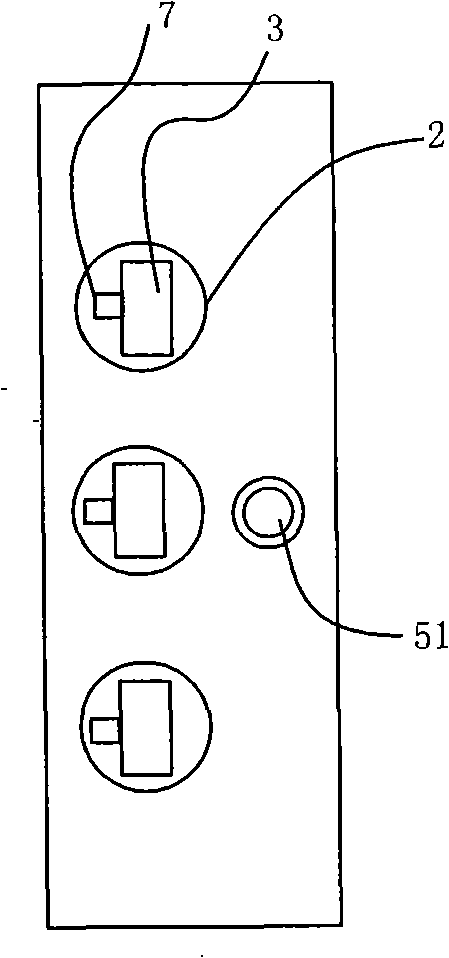

[0021] Implementation Mode 1: see Figure 1-Figure 3 .

[0022] This embodiment includes a high-voltage motor running power switch 1, and also includes an inductor coil 2, an inductor core 3, a driving mechanism 4, a transmission mechanism 5, a fixed bracket 6, and a track 7. For each phase of the high-voltage motor running power supply, The input and output terminals of the operating power switch 1 are all connected in parallel with the inductor coil 2 (see figure 1 ). From figure 2 It can be seen that the driving mechanism 4 can adopt all driving mechanisms in the prior art, such as a motor driving mechanism (motor-belt pulley or motor-gear, etc.) or a pneumatic driving mechanism (such as a cylinder-propelling rod, etc.) or a hydraulic driving mechanism (such as Hydraulic cylinder—promoting rod etc.), transmission mechanism 5 then adapts with driving mechanism. In this embodiment, the drive mechanism 4 adopts a motor-gear structure, and the transmission mechanism 5 adop...

Embodiment approach 2

[0023] Implementation mode two: see Figure 4

[0024] In addition to the high-voltage motor running power switch 1, inductor coil 2, inductor core 3, drive mechanism 4, transmission mechanism 5, fixed bracket 6, and track 7 provided in Embodiment 1, this embodiment also has a coil frame 8 Each inductor coil 2 is installed on the coil frame 8, the screw nut 52 of the transmission mechanism 5 is arranged on the coil frame 8, the screw rod 51 is rotatably installed on the fixed bracket 6, and the inductor core 3 is also fixed on the fixed bracket 6, the motor 41 of the driving mechanism 4 drives the screw rod 51 to rotate through the gear 42, so that the screw nut moves on the screw rod, so that the inductor coil 2 moves, and the inductor core 3 is inserted or withdrawn.

[0025] When the device of the present invention works, the low-voltage control power supply of the driving mechanism 4 is first connected, so that the motor 41 drives the transmission mechanism 5 and the indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com