Clamp device

A technology of clamping device and clamping rod, applied in the direction of clamping device, positioning device, clamping, etc., can solve the problems of increasing and reducing the risk of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

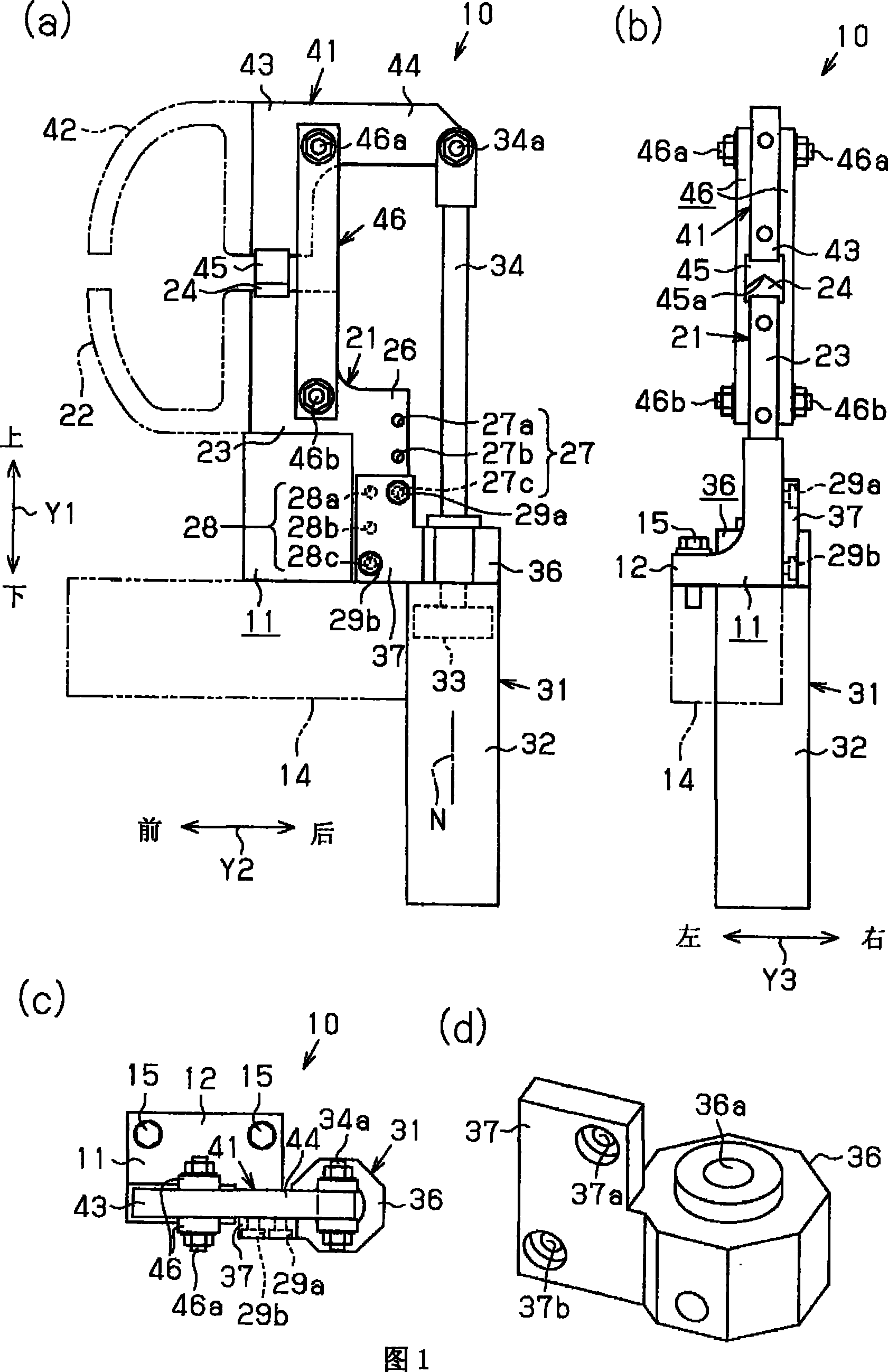

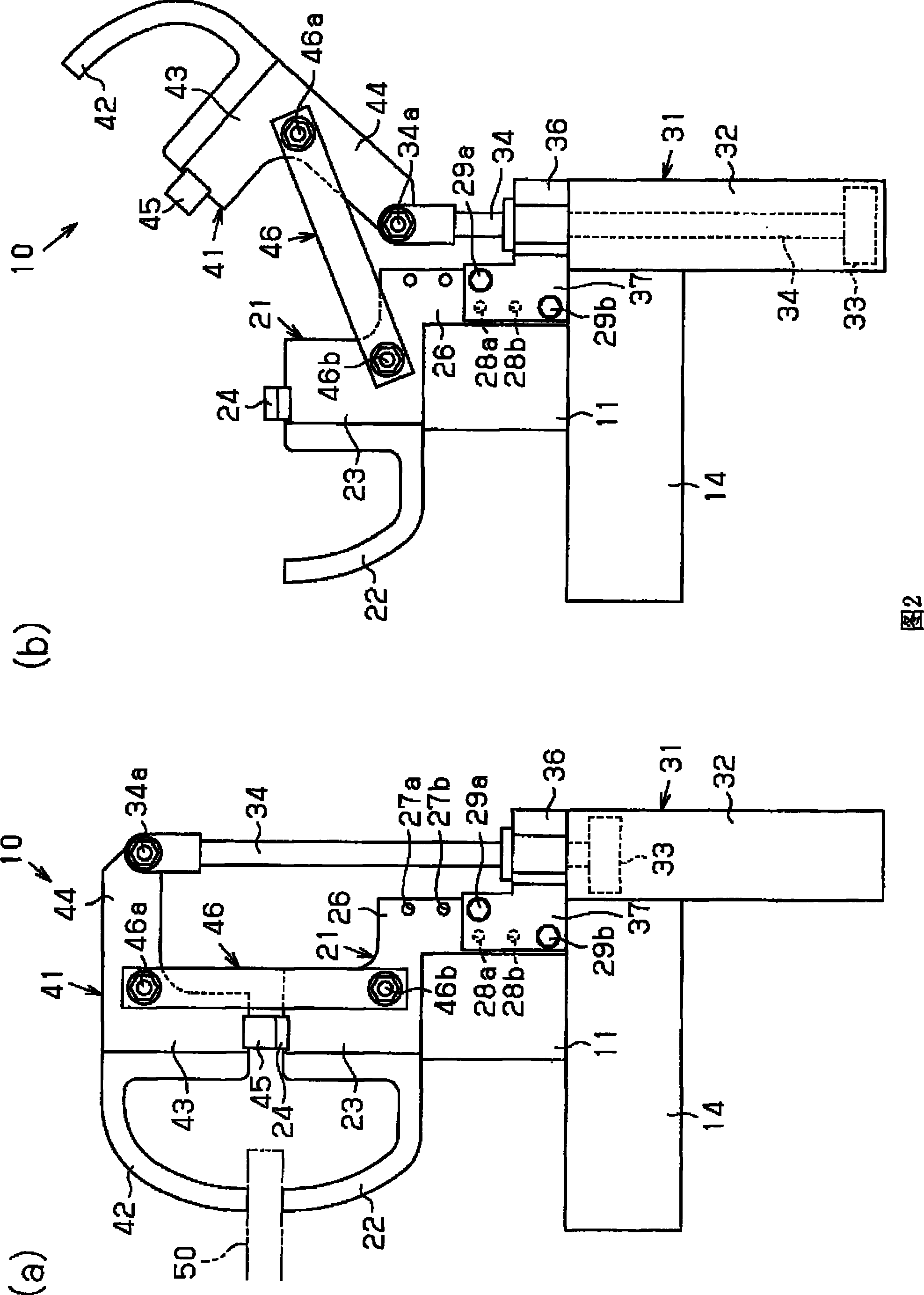

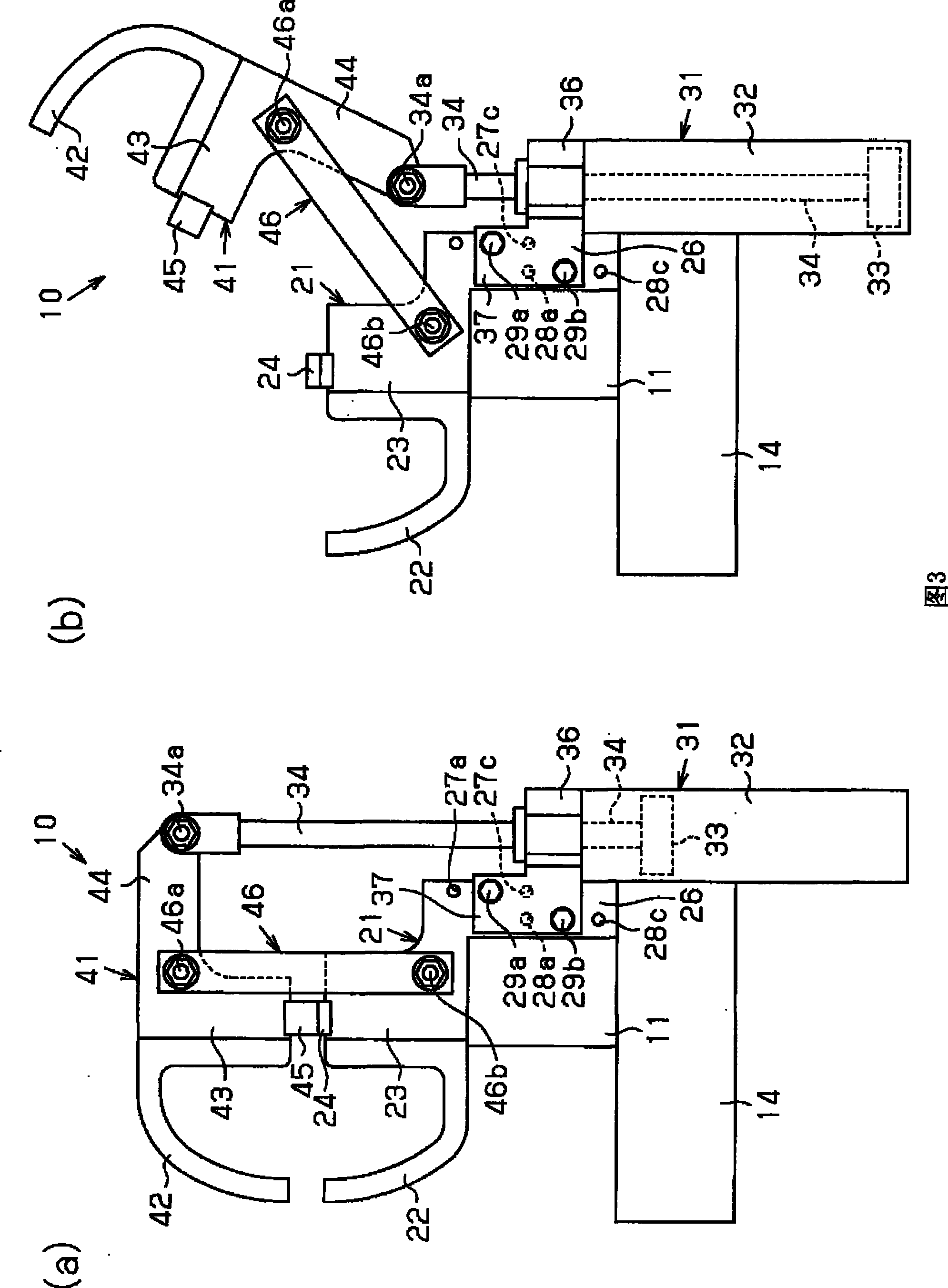

[0044] Hereinafter, a clamping device according to a first embodiment of the present invention will be described with reference to the drawings.

[0045] As shown in FIGS. 1( a ) to 1 ( c ), the clamping device 10 has a steel fixing portion 11 for fixing the clamping device 10 on a frame 14 . The fixing part 11 is L-shaped and has a base part 12 and a bottom 21 , the base part 12 extends laterally along a horizontal plane at the lower part of the fixing part 11 , and the bottom 21 is formed vertically upward from the base part 12 . The base plate portion 12 has a pair of front and rear holes (not shown) into which a pair of bolts 15 are inserted, and the base plate portion 12 is fixed to the frame 14 with the pair of bolts 15 passing through the holes.

[0046] The bottom 21 is formed in a flat plate shape so as to extend in the vertical and front-rear directions. The second rod attachment portion 23 corresponding to the front end of the bottom 21 is attached to the rear end ...

no. 2 example

[0077] Next, a second embodiment of the present invention will be described with reference to FIGS. 5( a ) to 8 . The same elements in the second embodiment as those in the first embodiment are given the same reference numerals, and descriptions thereof are omitted.

[0078] The clamping device 60 shown in Fig. 5 (a) and 5 (b) has the plate-like bottom 61 that extends along vertical direction and front-rear direction and has steel fixing part 62, and this steel fixing part 62 is screwed on by bolt 63a and A nut 63 b on the bolt 63 a is fixed to the right side surface of the bottom 61 . The clamp device 60 is fixed to the frame 14 indicated by the two-dot chain line in FIGS. 5( a ) and 5 ( b ) through a fixing portion 62 . Alternatively, the fixing portion 62 may be fixed on both the right side surface and the left side surface of the bottom 61 , and the clamping device 60 is fixed to the frame 14 through the two fixing portions 62 .

[0079] A second clamp lever 64 indicated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com