Lead screw transmission lifting rod

A technology of screw drive and lifting rod, which is applied to lifting frames, lifting devices, antenna supports/installation devices, etc., can solve the problems of difficulty in controlling the stability of the rod body, long erection time, easy to cause harm, etc., and save manpower. , The effect of good anti-icing performance and short lifting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

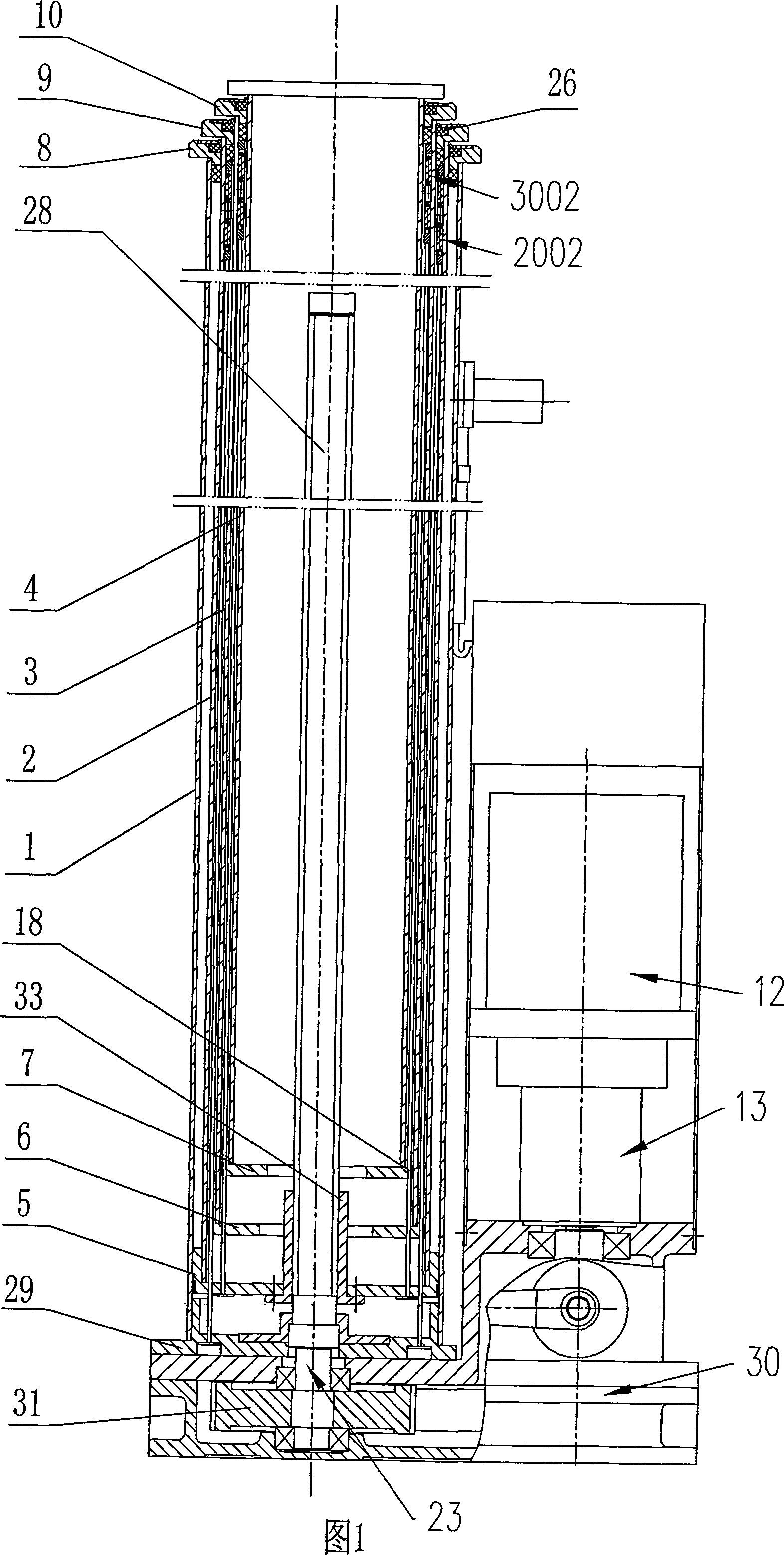

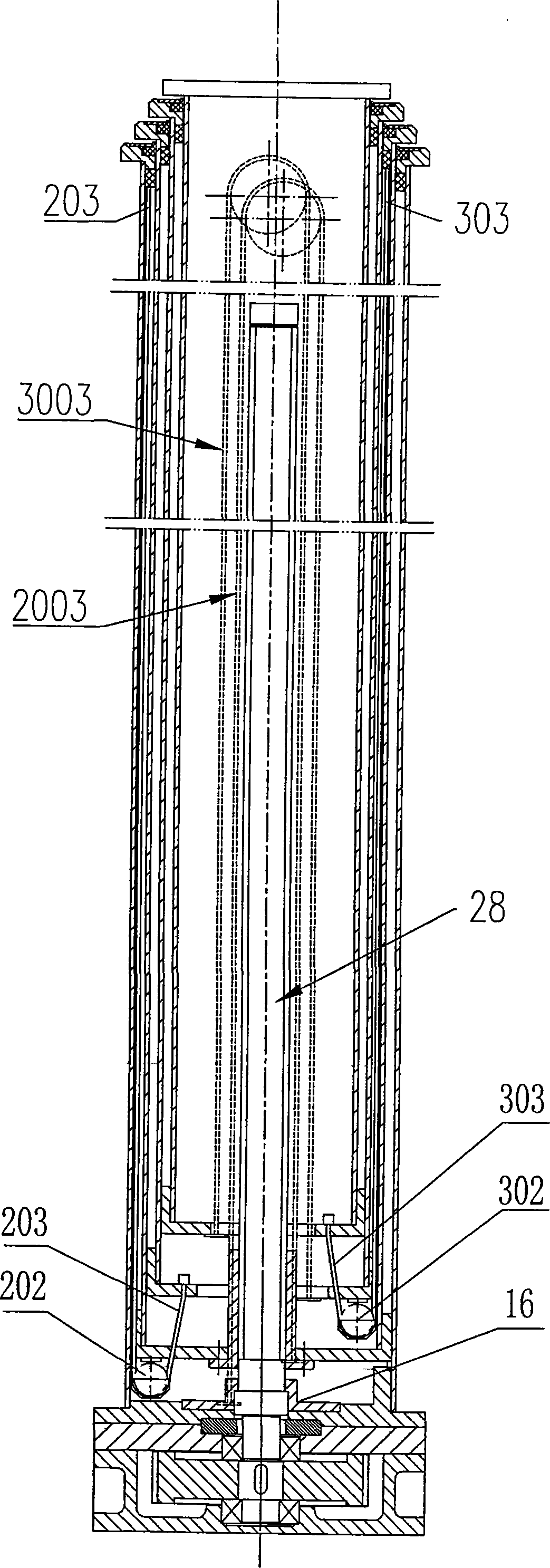

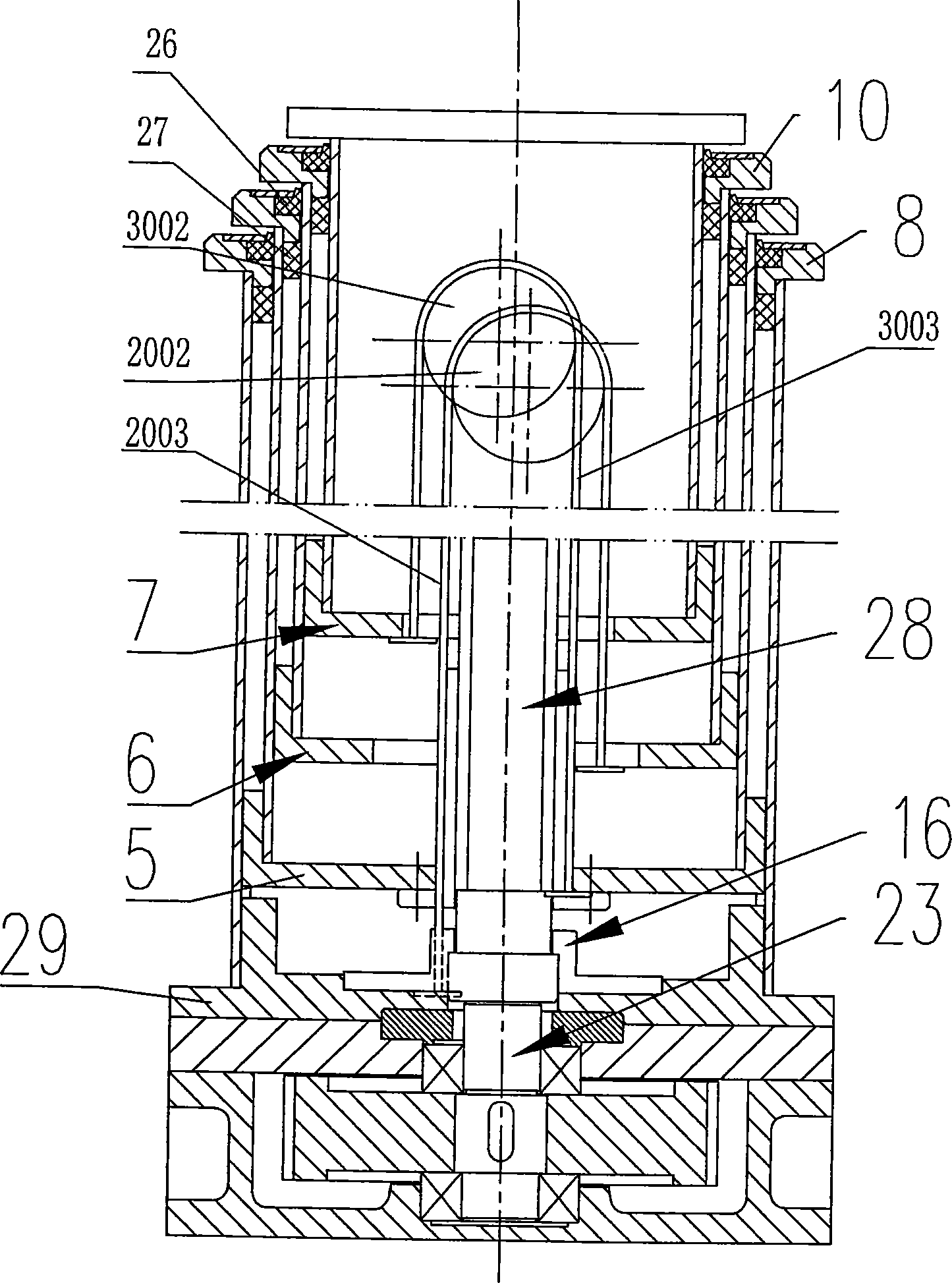

[0044] As shown in the figure, the lifting rod driven by the screw rod is stacked sequentially from the outside to the inside of the first casing 1, the second casing 2, the third casing 3, and the fourth casing 4; the adjacent casings are coaxial Swipe to connect. The bottom of the first casing 1 is set on the base 29 . The lower ends of the second bushing 2, the third bushing 3, and the fourth bushing 4 are fixedly connected with square sockets 5, 6, and 7, and the four corners of the outer walls of each socket are equipped with friction fits on the inner walls of the adjacent outer casings. Friction plate 18.

[0045] Top seals 8, 9, and 10 are respectively connected to the upper ends of the first casing 1, the second casing 2, and the third casing 3, and the inner side of each top seal is installed with a sealing ring 26 in contact with the outer wall of the adjacent inner casing; The sealing ring 26 is pressed on the top seal with a cover plate. Friction plates 27 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com