Electric stapler

A stapler and electric technology, applied in the direction of nailing U-shaped nail tools, nailing tools, manufacturing tools, etc., can solve the problems of relative position accuracy deterioration, binding ability decline, staple deformation, etc., and achieve easy disassembly steps Understand, manage and store the effect of easy and efficient molding/punching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

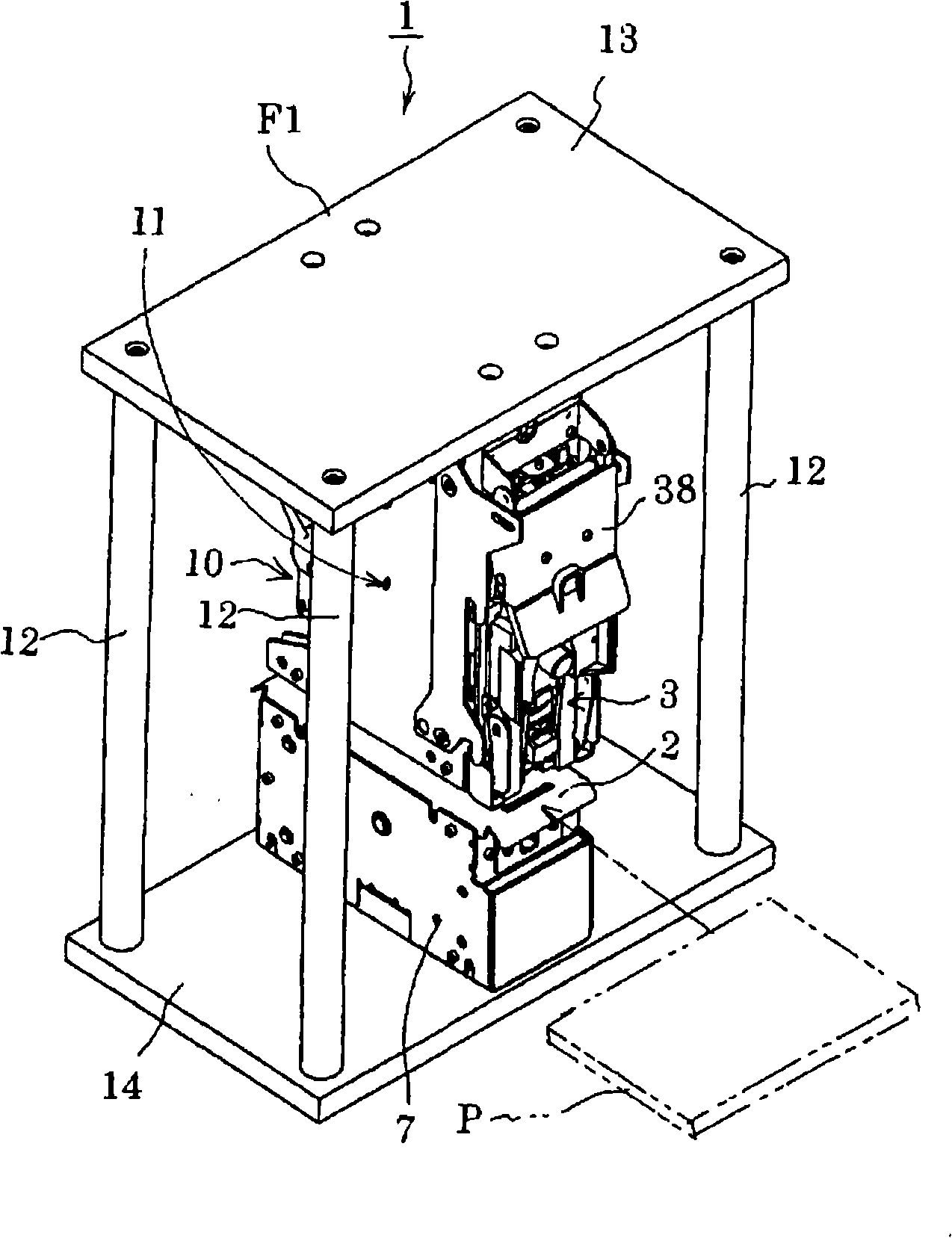

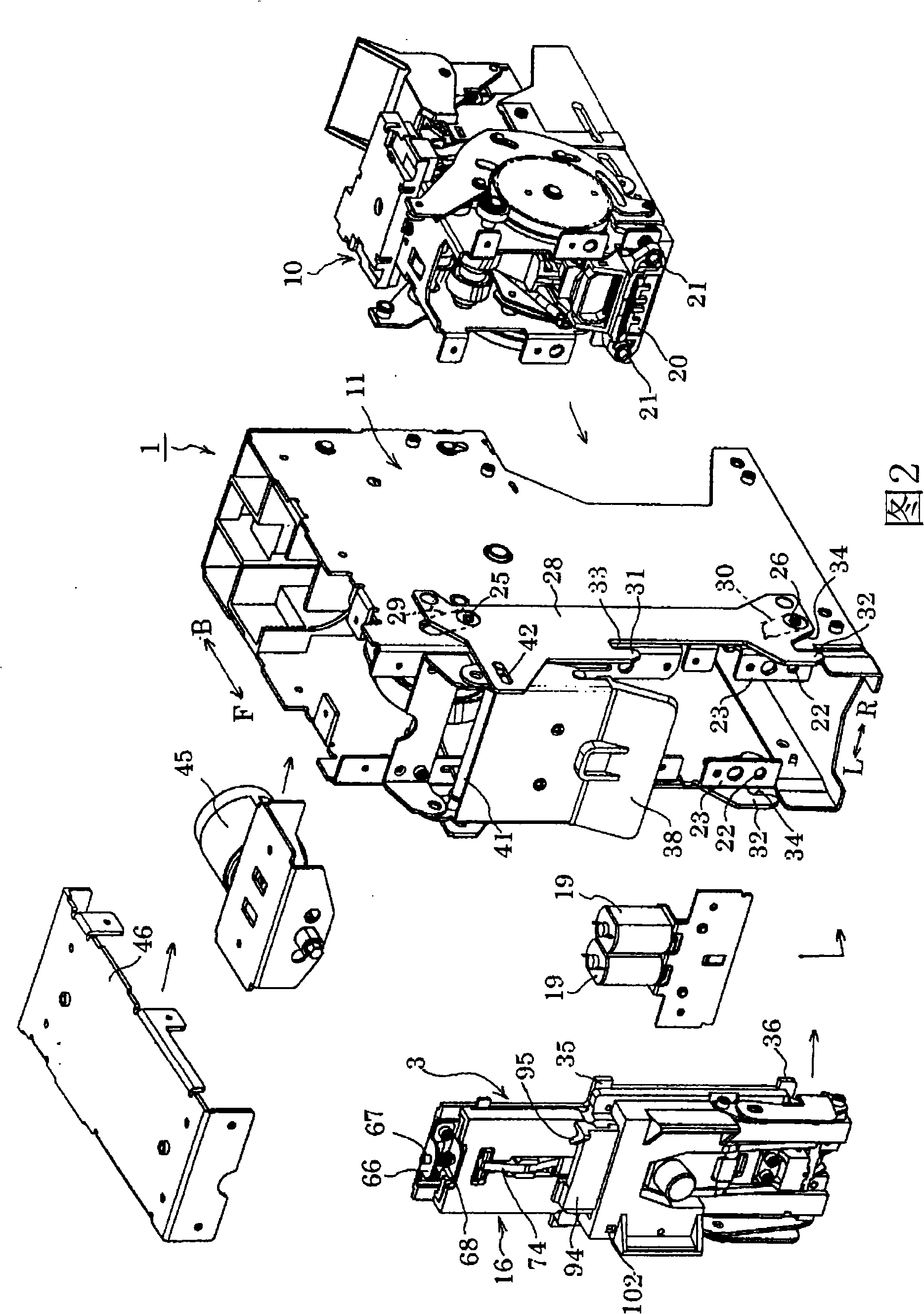

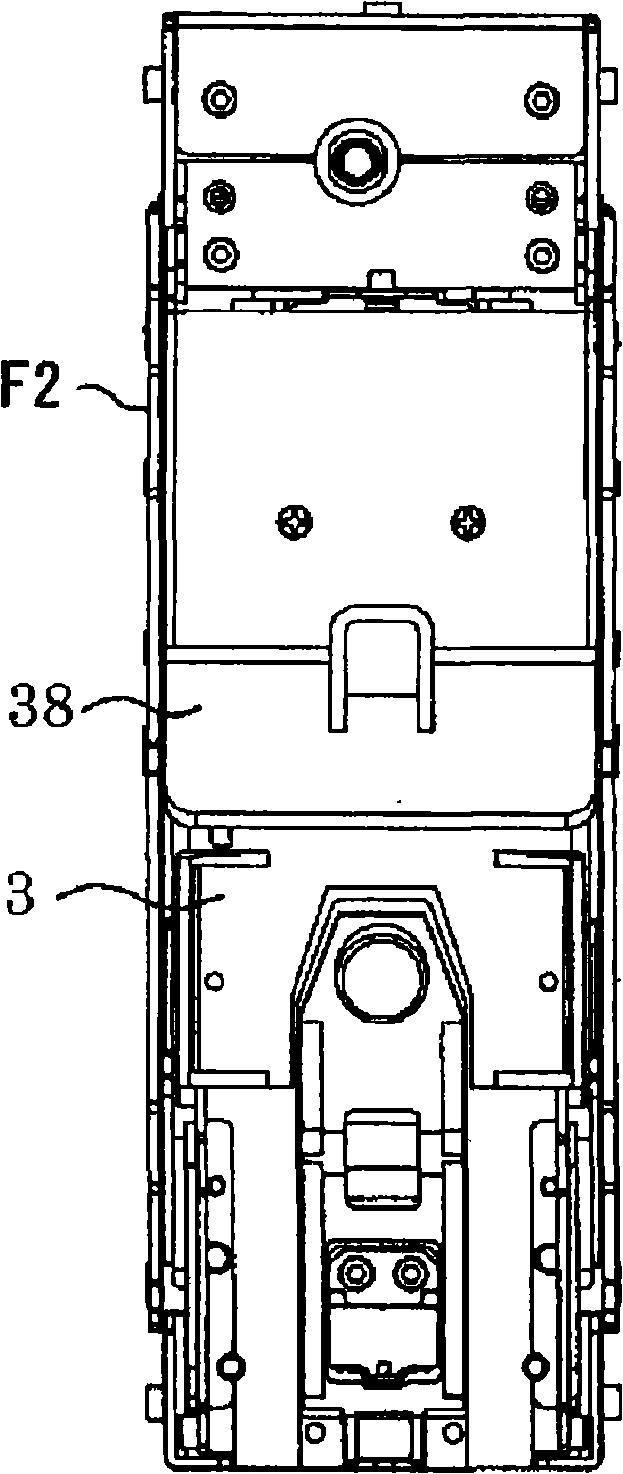

[0173] Below, refer to Figures 1 to 22B An embodiment of the present invention will be described. In the electric stapler 1 of the embodiment, the paper P is placed on the paper table 2, and the forming part 4, the driver part 5, and the slider part 6 constituting the driver assembly 3 are lowered and moved to the lower side of the jaw part 7. The driver plate 9 of the driver part 5 drives out the needle S formed by the forming plate 8 of the forming part 4 and makes it penetrate the paper P, and folds the legs of the needle S with the movable clamp (not shown) of the clamp part 7. bend.

[0174] In one embodiment of the present invention, a driving rod is used to drive the slider part 6 and the driver part 5 that the action stroke is close to, on the slider part 6, so that the upper end and the lower end of the slider latch 74 can be aligned with The front surfaces of the driver parts 5 and 17 are in contact with each other at predetermined positions, and long holes 82 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com