Casting method of jewellery with large opening cavity, production method of the jelly mould and jelly mould

A production method and open-type technology, applied in jewelry, clothing, applications, etc., can solve problems such as inability to draw cores, and achieve the effect of increasing selling points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

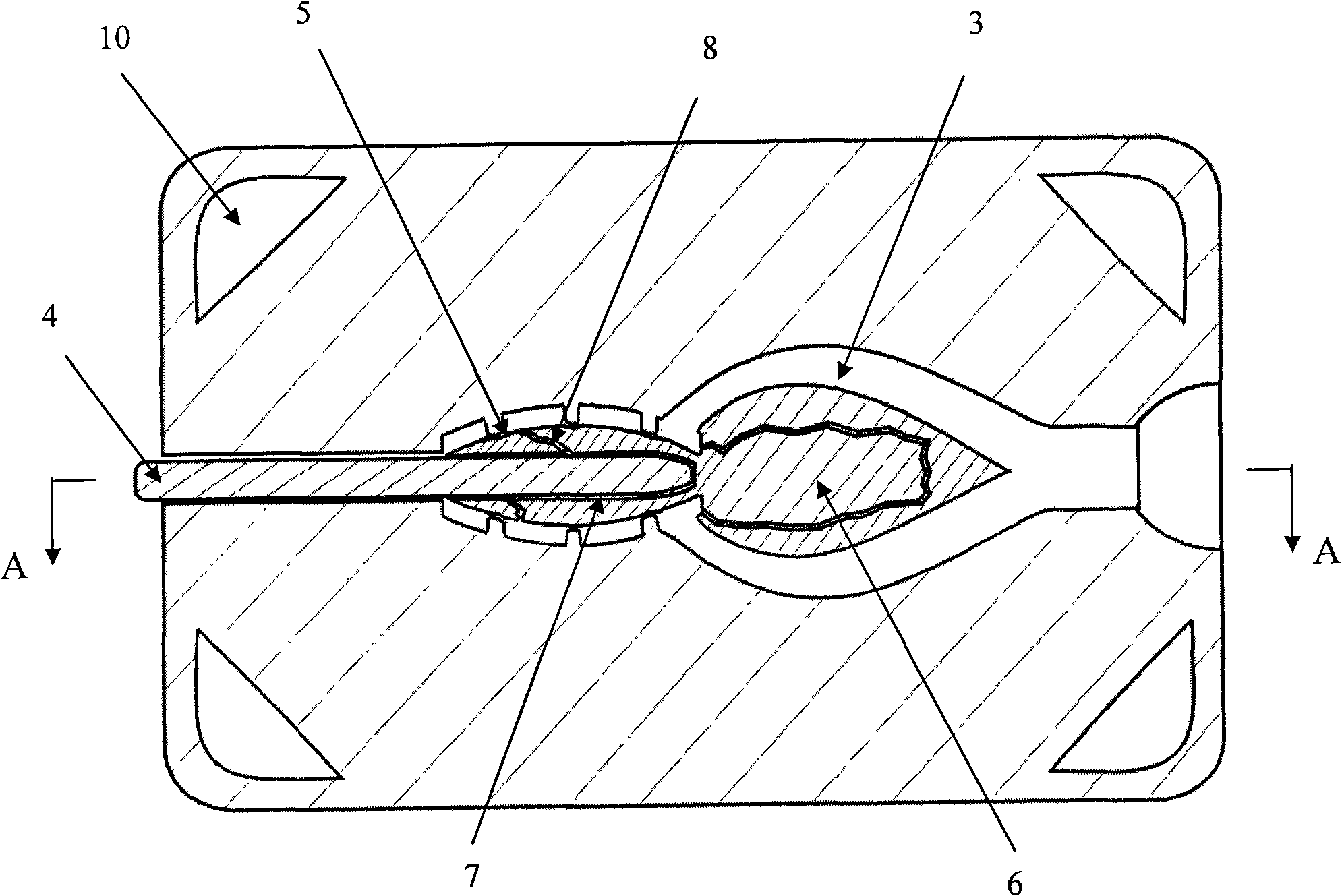

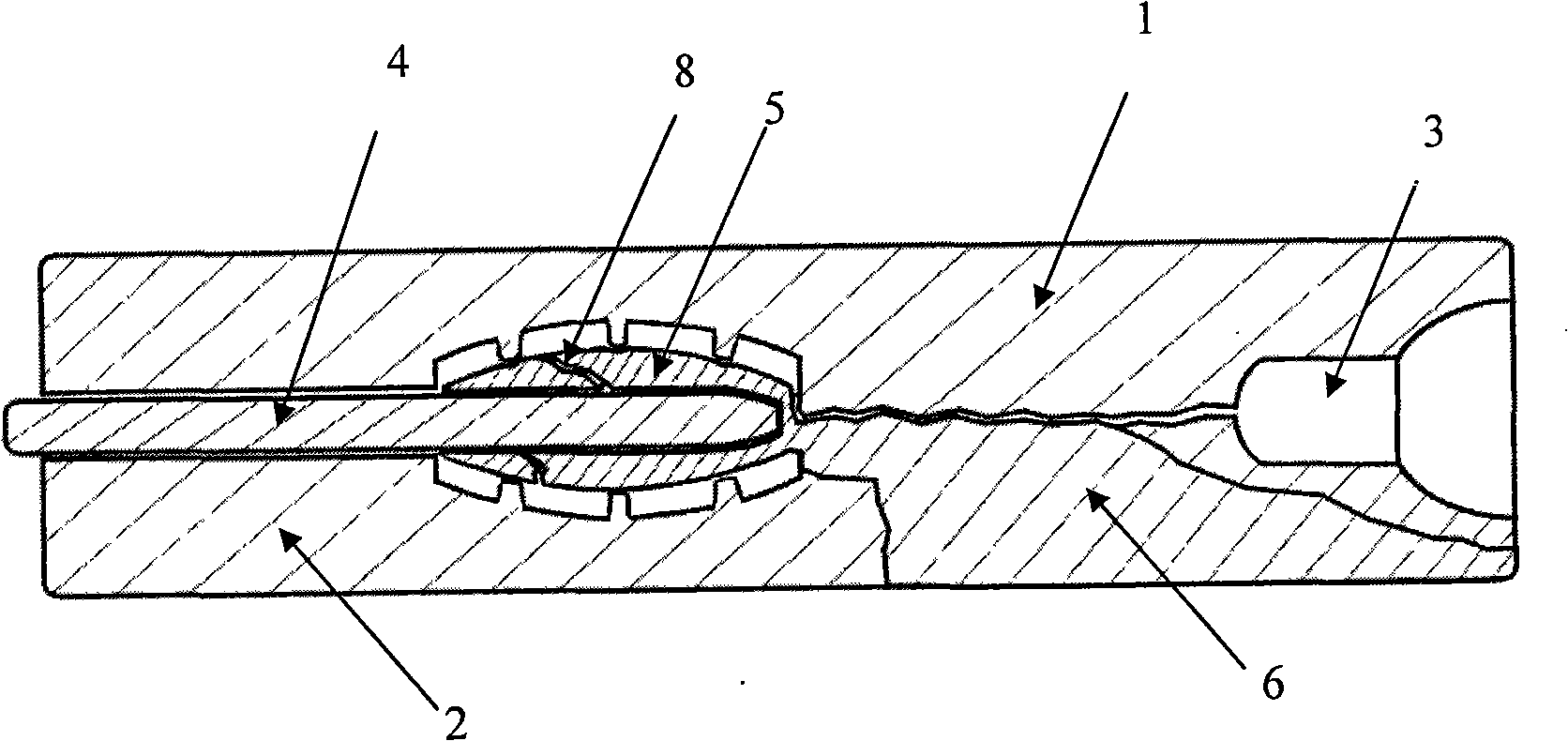

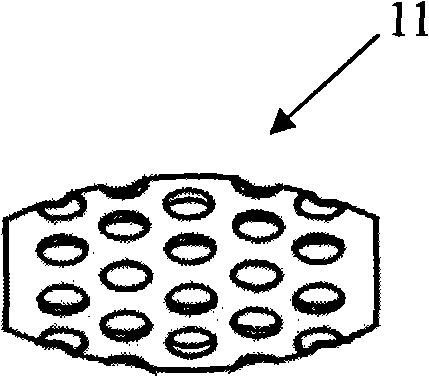

[0038] In order to solve the problems existing in the rubber mold used in the casting process for manufacturing jewelry with an open cavity in the prior art, the invention provides a rubber mold and a manufacturing method thereof. Taking the hollow olive-shaped jewelry as an example, the hollow part of the hollow olive-shaped jewelry is provided with openings at both ends, and the maximum size of the cavity of the jewelry is larger than the size of the opening, that is, a cavity with a large middle and a small opening is formed. Such as figure 1 , 2 , 3, 4, 5, 6, and 7, the rubber mold includes an upper mold 1, a lower mold 2, a mold core arranged in the cavity of the upper and lower mold 2, and a pouring mold is provided between the upper mold 1 and the lower mold 2. Road 3, the mold core includes an outer core 4 and an inner core 5. Wherein, the mold cavity after the upper and lower molds 2 are molded is the same olive shape as the finished product of the jewelry, and is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com