Extruder double passage barrel heating cooling device

A barrel heating and cooling device technology, which is applied in the field of barrel heating and cooling devices, can solve the problems of large energy consumption, large thermal inertia and cold inertia, and large control temperature fluctuations, so as to reduce energy consumption, reduce temperature fluctuations, and improve efficiency effect

Inactive Publication Date: 2008-10-22

恒力石化股份有限公司

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Normally, the barrel of a twin-screw plastic extruder relies on the heater and cooling water for heating and cooling exchanges, both the external heating of the barrel and the internal water cooling of the barrel to ensure that the extruder barrel and screw are running This method is widely used in the field of extruders. In the application, it is found that the thermal inertia and cold inertia of this method are very large, the control temperature fluctuates greatly, and the energy consumption is large.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

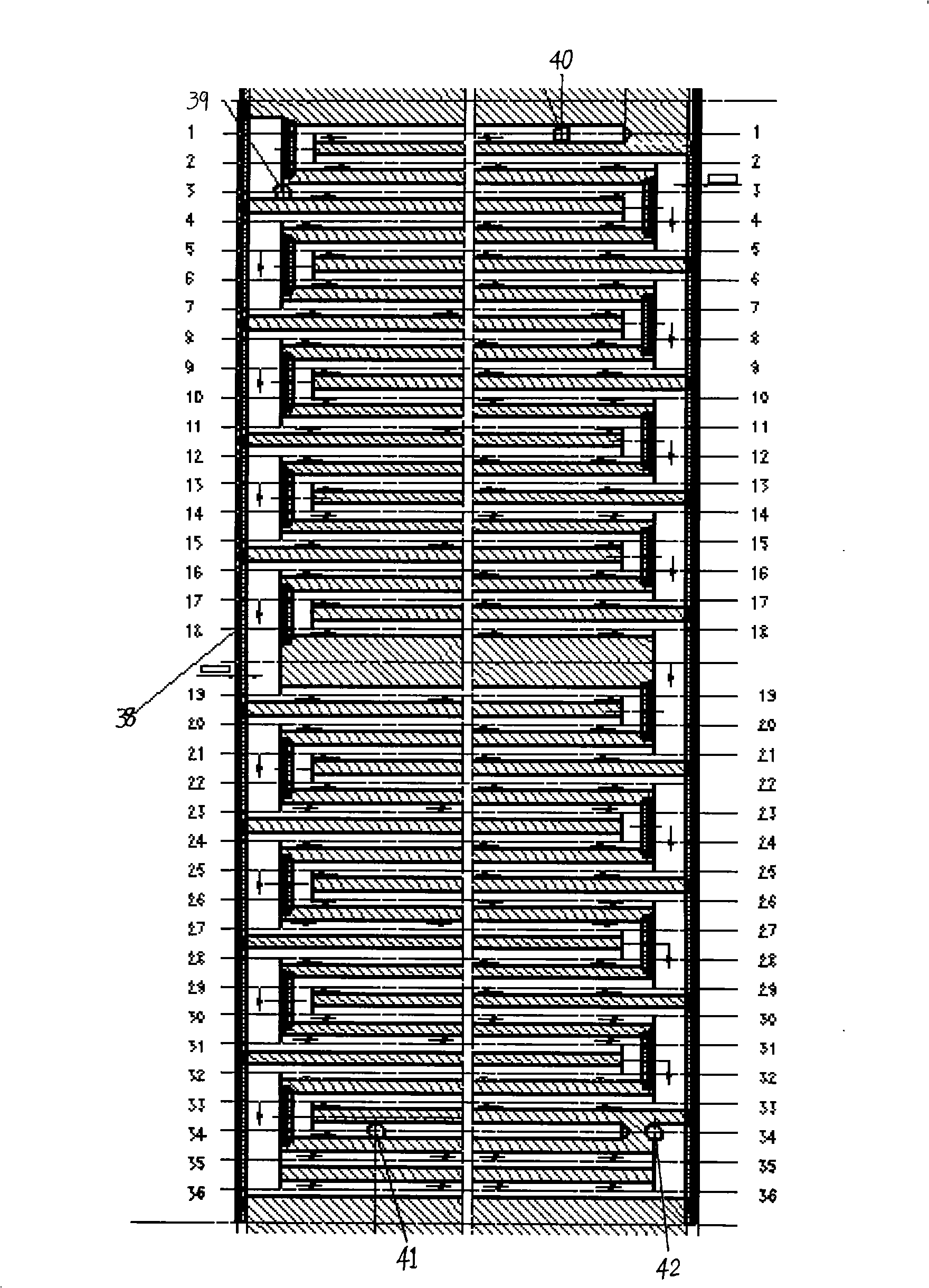

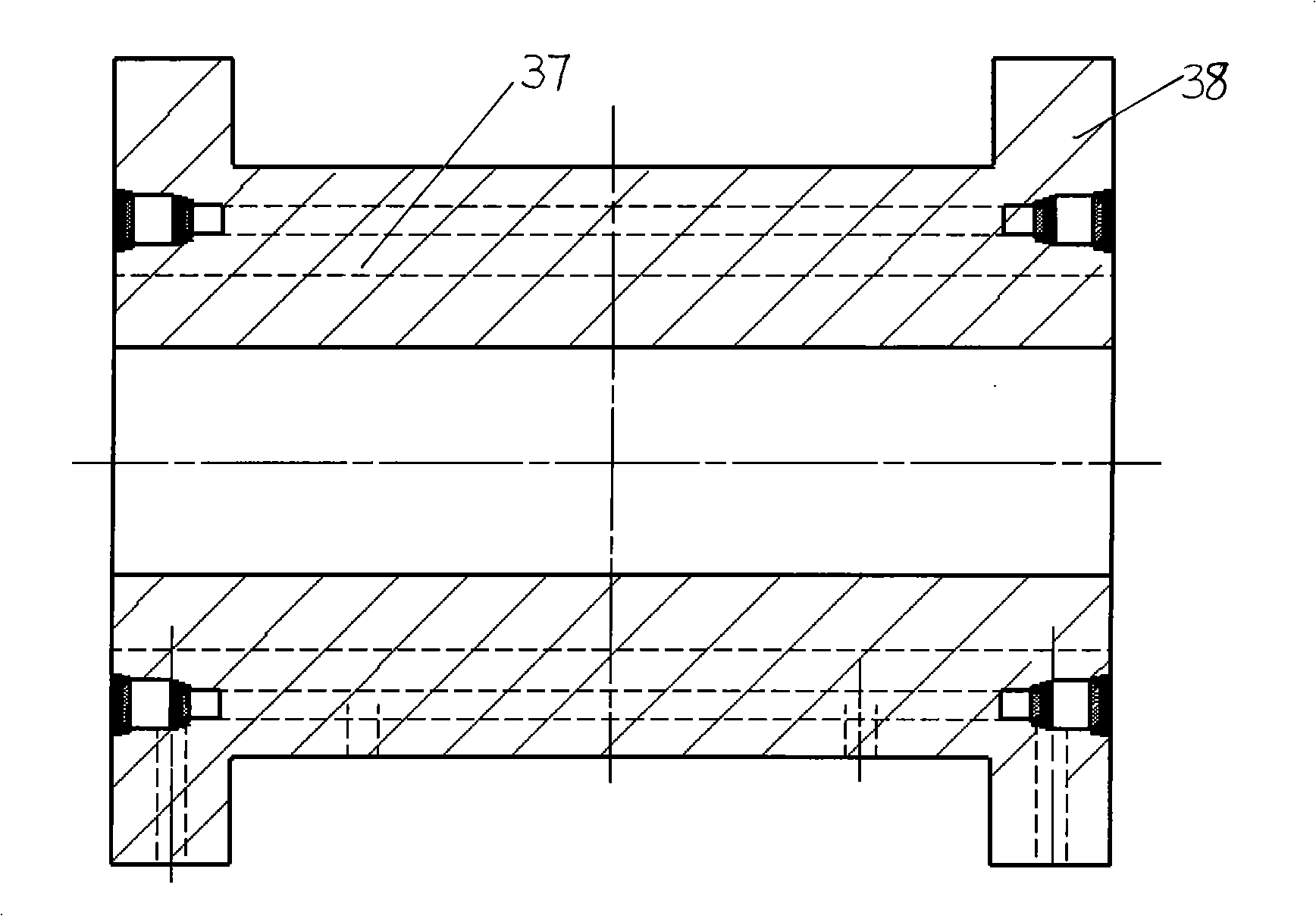

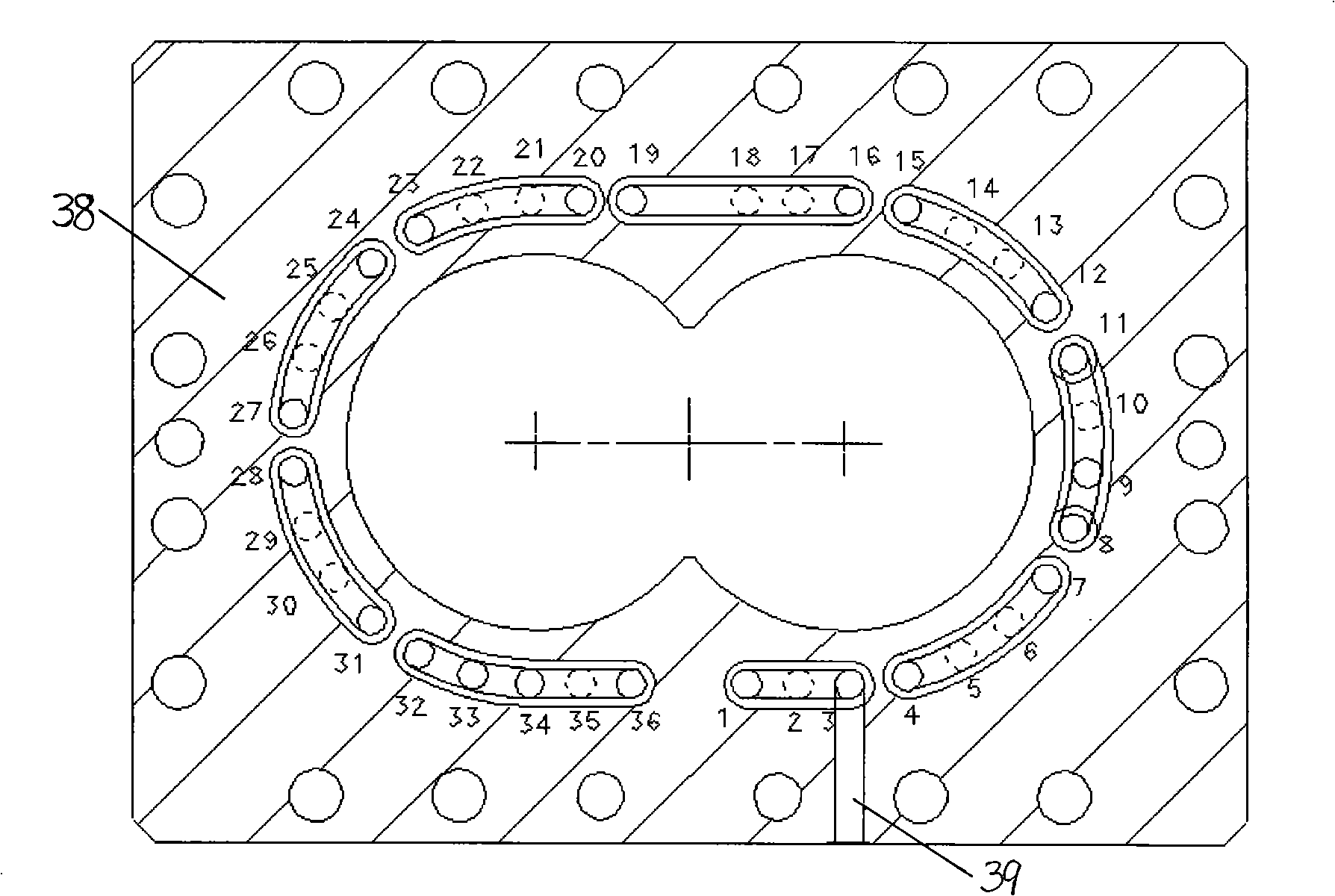

The invention relates to an extruding machine, in particular to the extruding machine with double flow passages machine cylinder heating and cooling devices. Two strips of double flow passages that are not communicated with each other are processed at the interior of the machine cylinder and respectively relate to a heating flow passage and a cooling flow passage; two ends of each flow passage are respectively an oil inlet and an oil outlet. The invention changes the traditional thermal balance principle from another view; the heating and the cooling are finished by heat transfer oil; the heating oil and the cooling oil are carriers for thermal balance; the machine barrels of the double flow passages are main bodies for the heating oil and the cooling oil to carry out heat exchange. The two flow passages are not communicated with each other, only the reciprocating flow is carried out along the axial direction in parallel; therefore, the machine can run normally when the machine cylinder is ensured to be controlled under the required temperature.

Description

Extruder dual-channel barrel heating and cooling device 1. Technical field The invention relates to a twin-screw plastic extruder, in particular to a barrel heating and cooling device. 2. Background technology Normally, the barrel of a twin-screw plastic extruder relies on the heater and cooling water for heating and cooling exchanges, both the external heating of the barrel and the internal water cooling of the barrel to ensure that the extruder barrel and screw are running This method is widely used in the field of extruders. It is found in the application that the thermal inertia and cold inertia of this method are very large, the control temperature fluctuates greatly, and the energy consumption is large. 3. Contents of the invention The purpose of the present invention is to overcome the above disadvantages and provide a heating and cooling device for extruder double-channel barrel, which has stable and uniform temperature control, small thermal and cooling inertia...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C47/82

Inventor 杨宥人张炜殷秋娟张福国

Owner 恒力石化股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com