J-shape stacked water-cleaning tank for knitting tubular open width refining rinsing combination machine

A combined machine and water washing box technology is applied in the processing of textile materials, textile and paper making, and dumping textile materials, etc. It can solve the problems of high production cost, high water consumption, large diameter and size of grey cloth, and achieve low production cost, Stabilizing effect of bleaching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

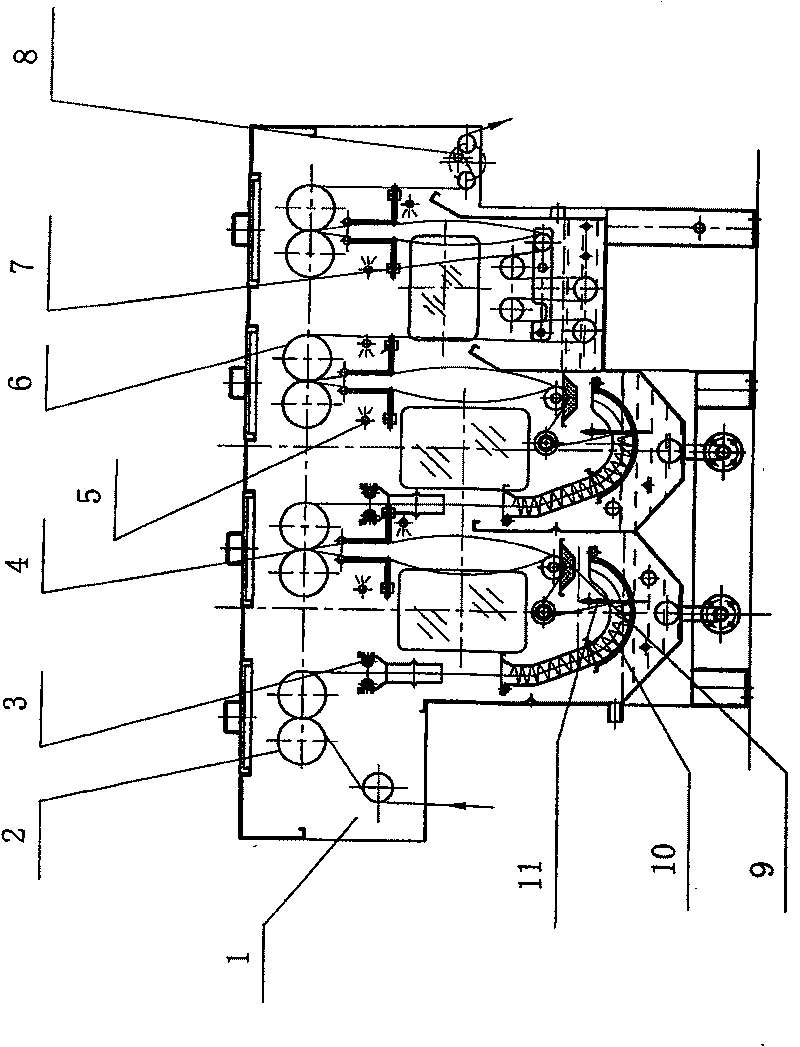

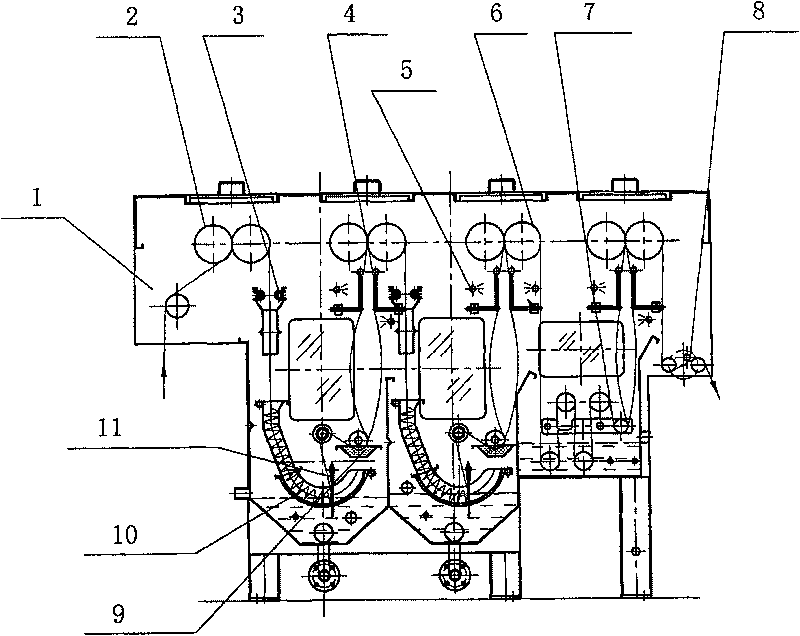

[0009] see figure 1 , the invention relates to a "J" type stacking washing box of a knitting tubular open-width combined refining and bleaching machine. It mainly consists of washing box body 1, cloth feeding roller 2, cloth feeding spray device 3, air blowing and bubbling device 4, cloth discharging spray device 5, cloth discharging roller 6, synchronous controller I 7, synchronous controller II8, Small water tank 9, J type stacking box 10 and synchronous controller III11 form. The bottom of the washing box body 1 is stepped, and the bottom end surface of the rear part is higher than the bottom end surface of the middle part and the front part. There are many J-shaped stacking boxes 10 (two in the figure), and the front and rear are arranged side by side in the water washing box. The front part of the box body 1 and the lower part of the middle part, there are also many cloth feeding spray devices 3 and synchronous controllers III11, the number of which is the same as the nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com