Multi-stage inner circulation anaerobic reactor

An anaerobic reactor and internal circulation technology, applied in anaerobic digestion treatment, waste fuel, etc., can solve the problems of difficult separation of sludge and hydraulic retention time, high solid content of effluent, imperfection, etc., and achieve optimal settlement conditions , enhanced mass transfer, and the effect of large fluid circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

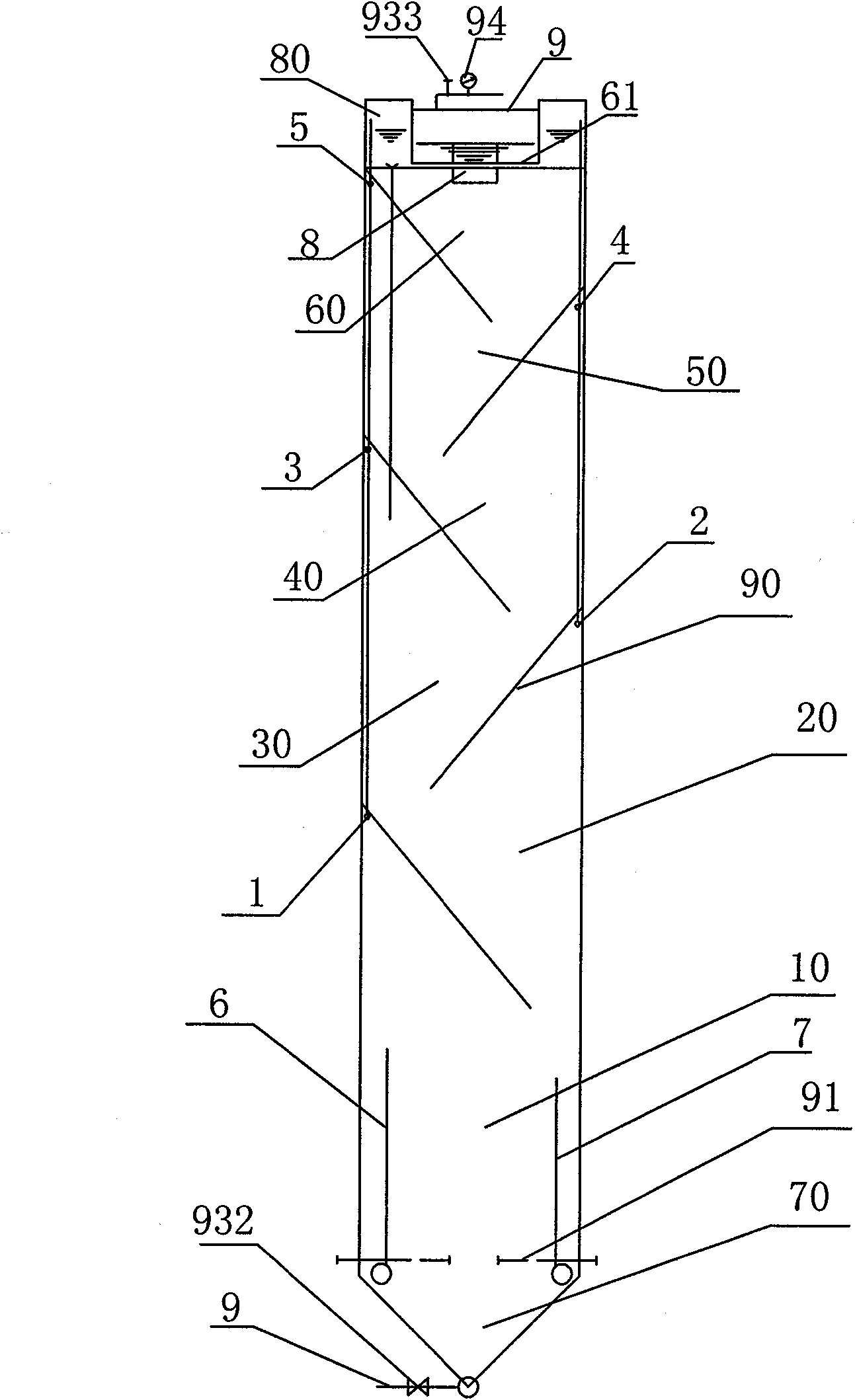

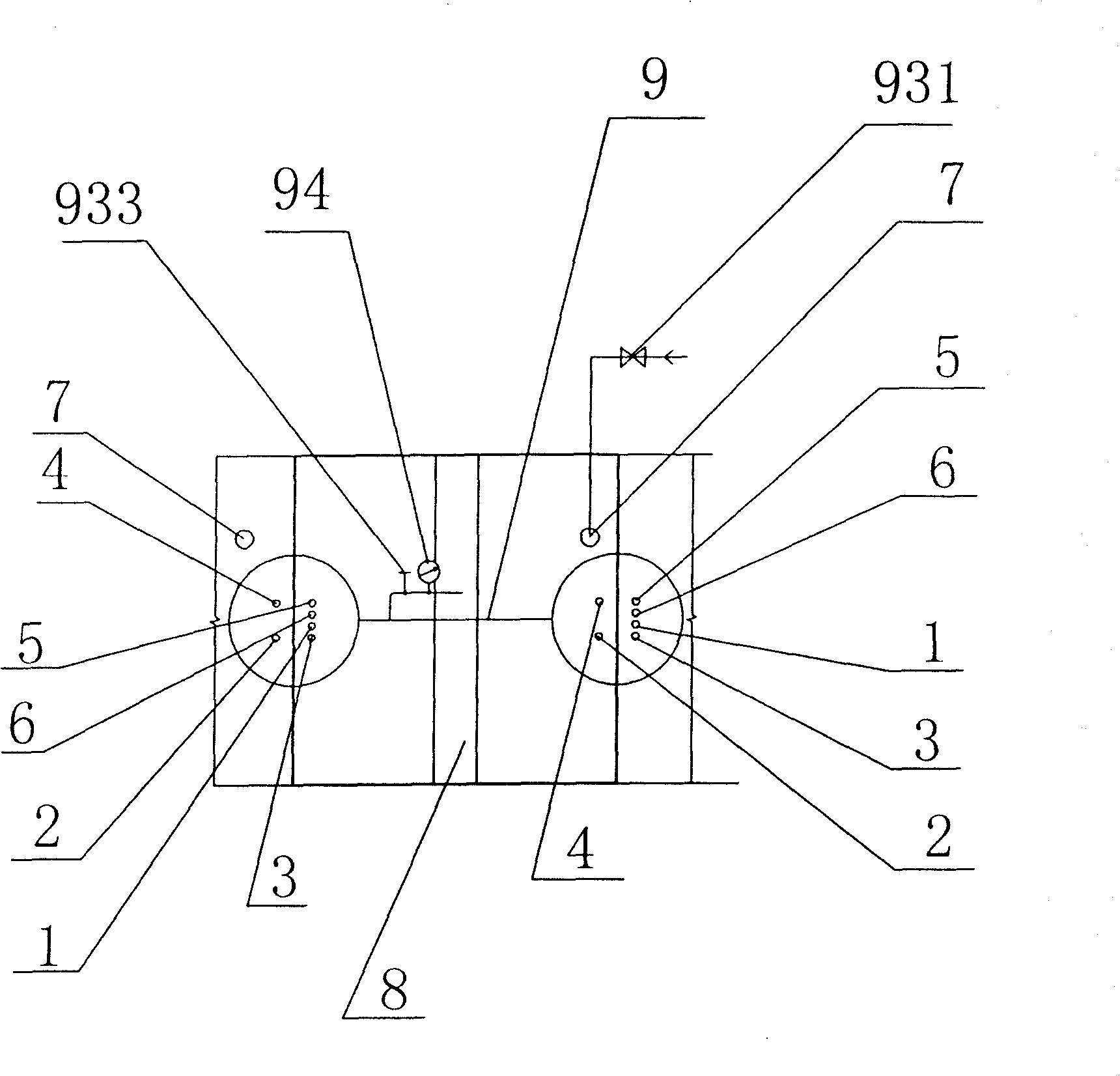

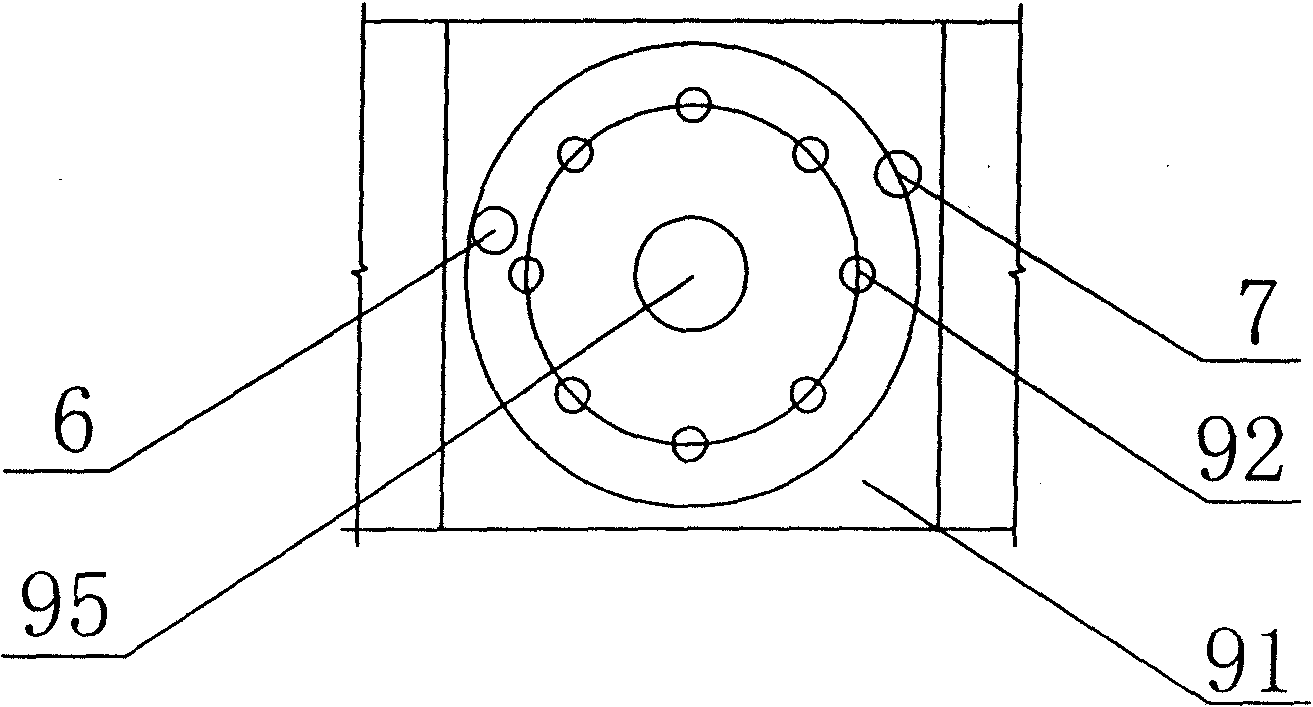

[0019] See figure 2 , the pretreated waste water is controlled by valve one 931 and enters the water inlet pipe 7 to connect to the solid-liquid separator 70. The solid-liquid separator 70 is conical; heavy solids are collected at the bottom center of the solid-liquid separator 70 and discharged through the control of pipeline one 9 and valve two 932 Separately, easily degradable substances and suspended substances pass through the water distribution plate 91 and the water distribution inclined pipe 92 to connect to the first reaction zone 10, and the first reaction zone 10 passes through the gas collection reflection plate 90 to connect to the second reaction zone 20, and the second reaction zone 20 passes through the gas collection reflection plate 90 is connected to the third reaction zone 30, the third reaction zone 30 is connected to the fourth reaction zone 40 through the gas-collecting reflector 90, the fourth reaction zone 40 is connected to the fifth reaction zone 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com