Spiral flow constant-pressure pump

A spiral flow constant pressure pump and pump casing technology, which is applied to pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve the problem of low pressure in swirl flow constant pressure pumps, and achieve high outlet pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

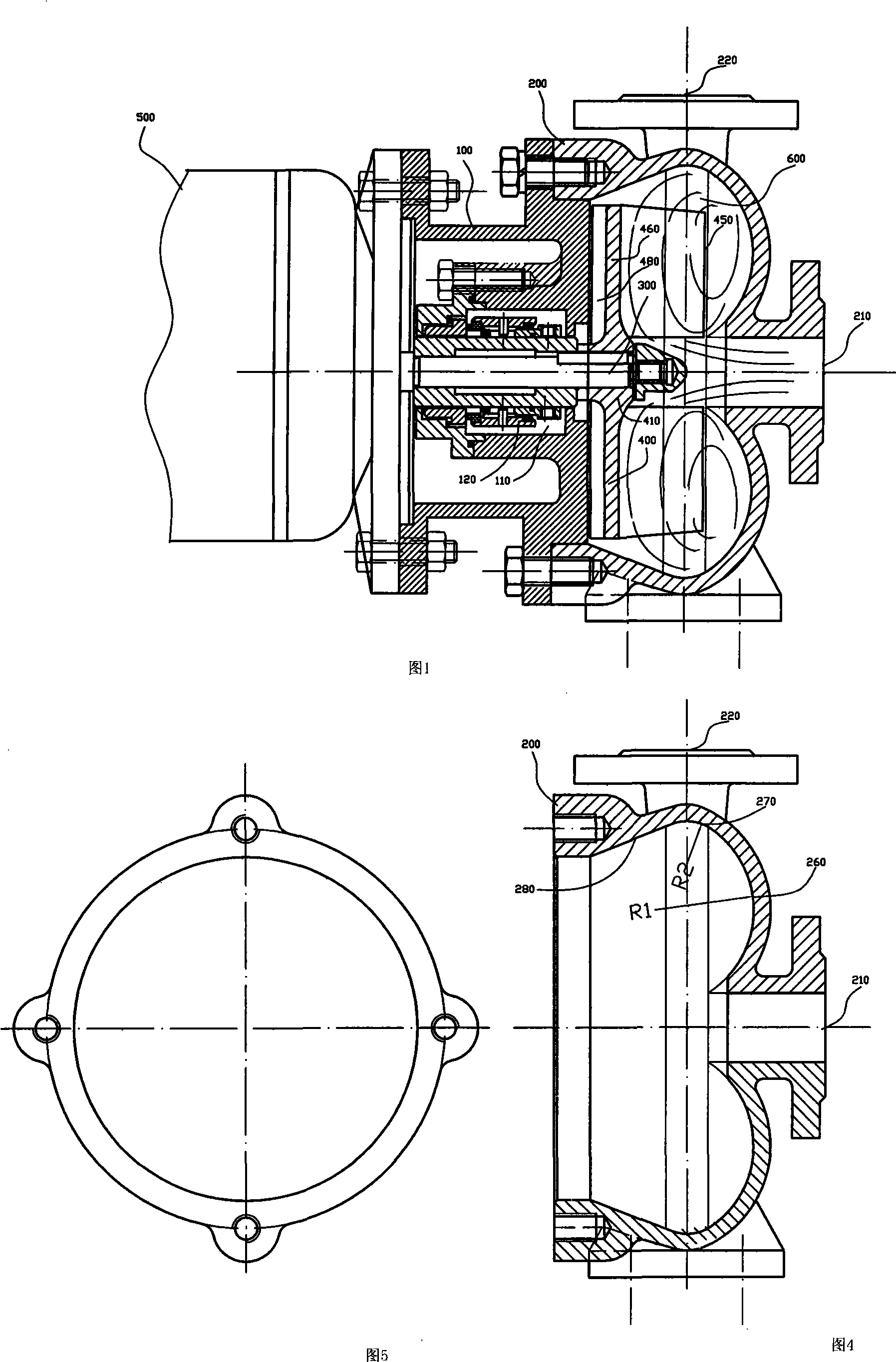

[0024] Referring to FIG. 1 , the spiral flow constant pressure pump of the present invention includes a pump body 100 , a pump casing 200 , a pump shaft 300 , an impeller 400 and a motor 500 .

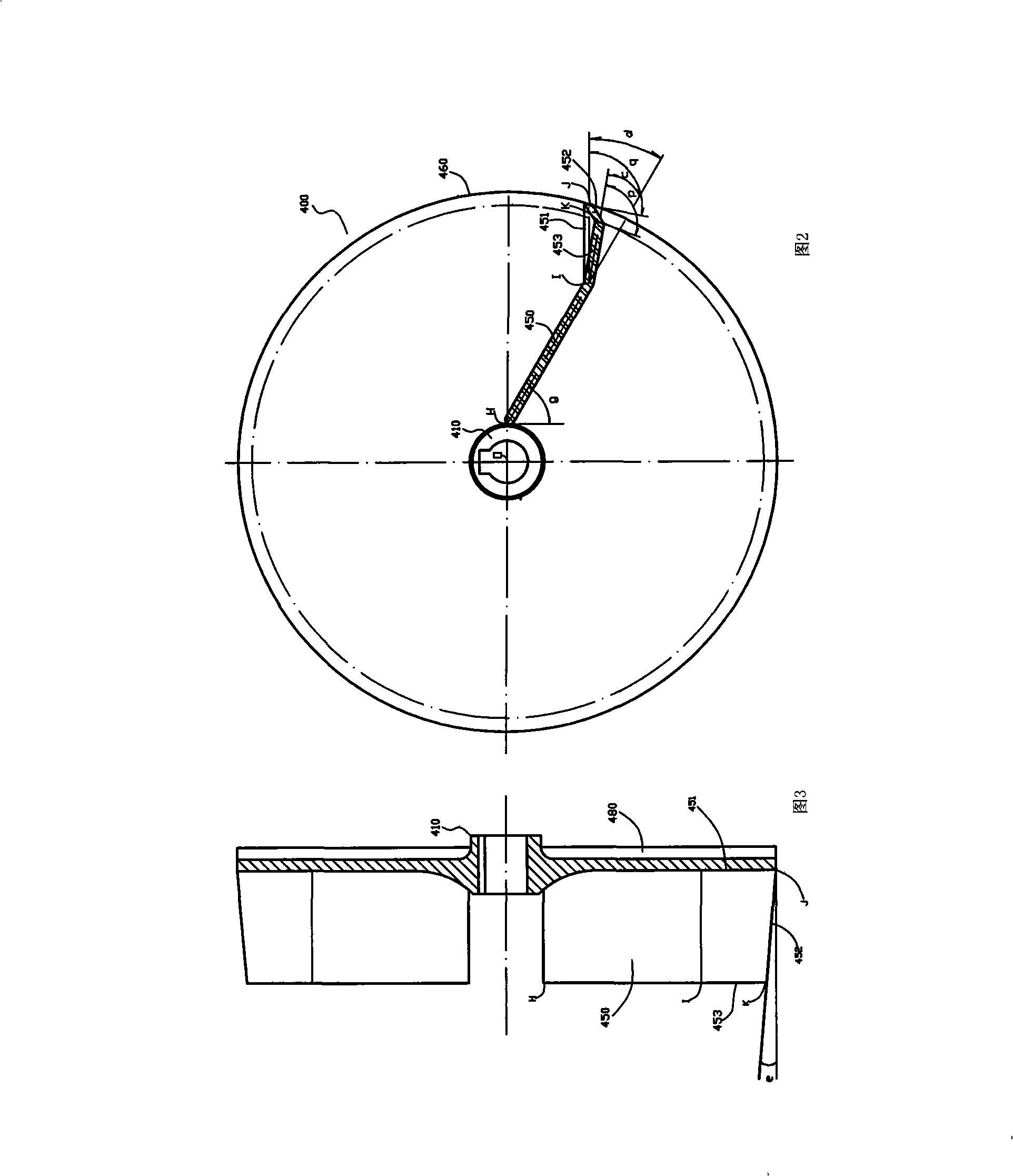

[0025] The pump casing 200 is fixedly installed on the front side of the pump body 100 , and the pump casing 200 and the pump body 100 jointly form a pump chamber 600 . The motor 500 is fixedly installed on the rear side of the pump body 100 . The shaft of the electric motor 500 serves as the pump shaft 300 . The front end of the pump shaft 300 protrudes into the pump chamber 600 , and the impeller 400 is fixedly installed on the front end of the pump shaft 300 . The pump body 100 has a central sealed cavity 110 . A set of known face seals or mechanical seals 120 is installed in the central seal cavity 110 . The pump housing 200 has a horizontal liquid inlet 210 on the front side and a vertical liquid outlet 220 on the right side. The impeller 400 includes a rear shroud 460 having ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com