Method and device for positioning quick elastic bar fastener embedded parts

A technology of positioning device and embedded parts, applied in the direction of road, track, ballast layer, etc., can solve the problems of large error, defective sleeper and high rejection rate, achieve small maintenance, improve installation efficiency, reduce vibration and wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

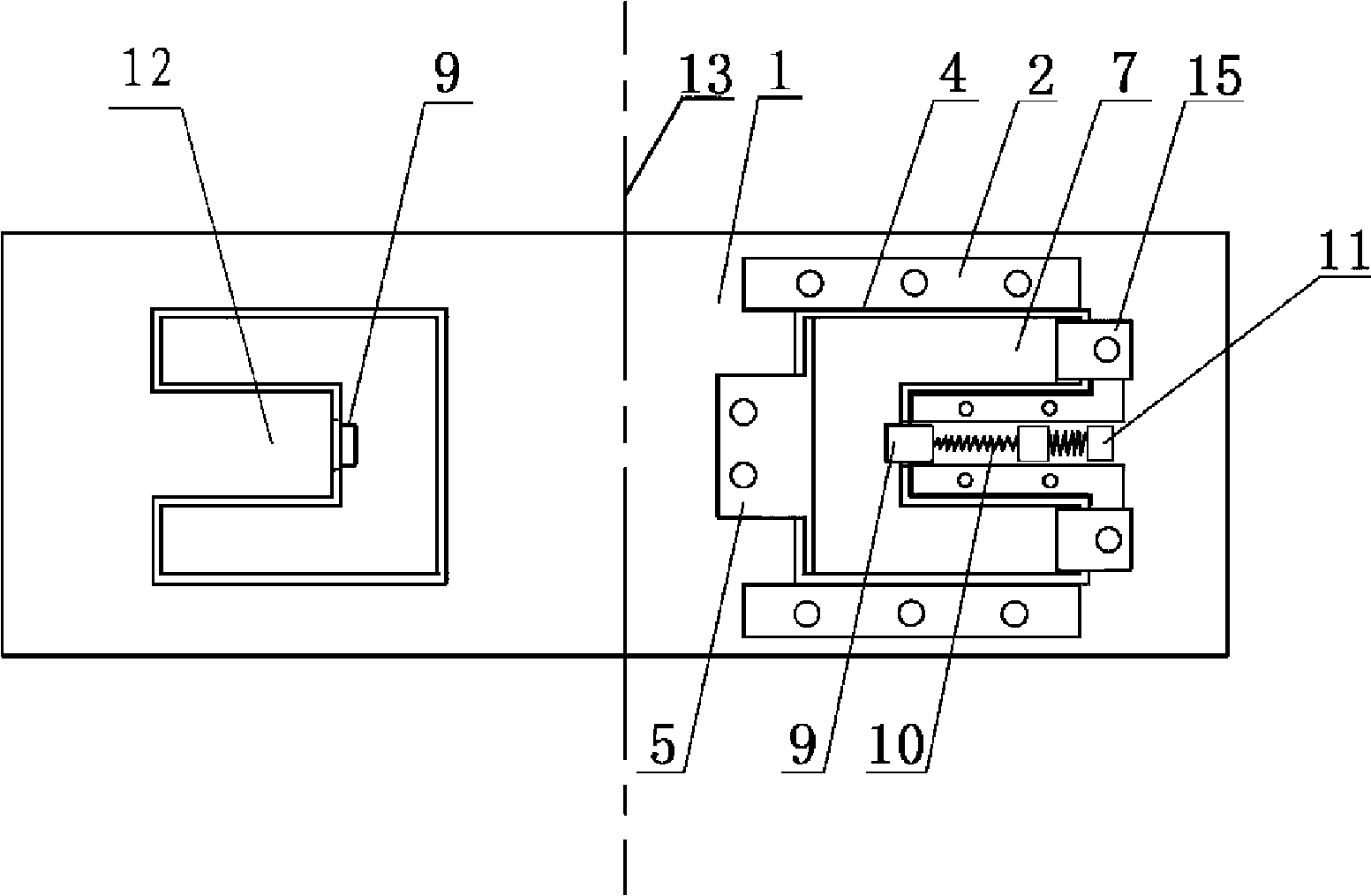

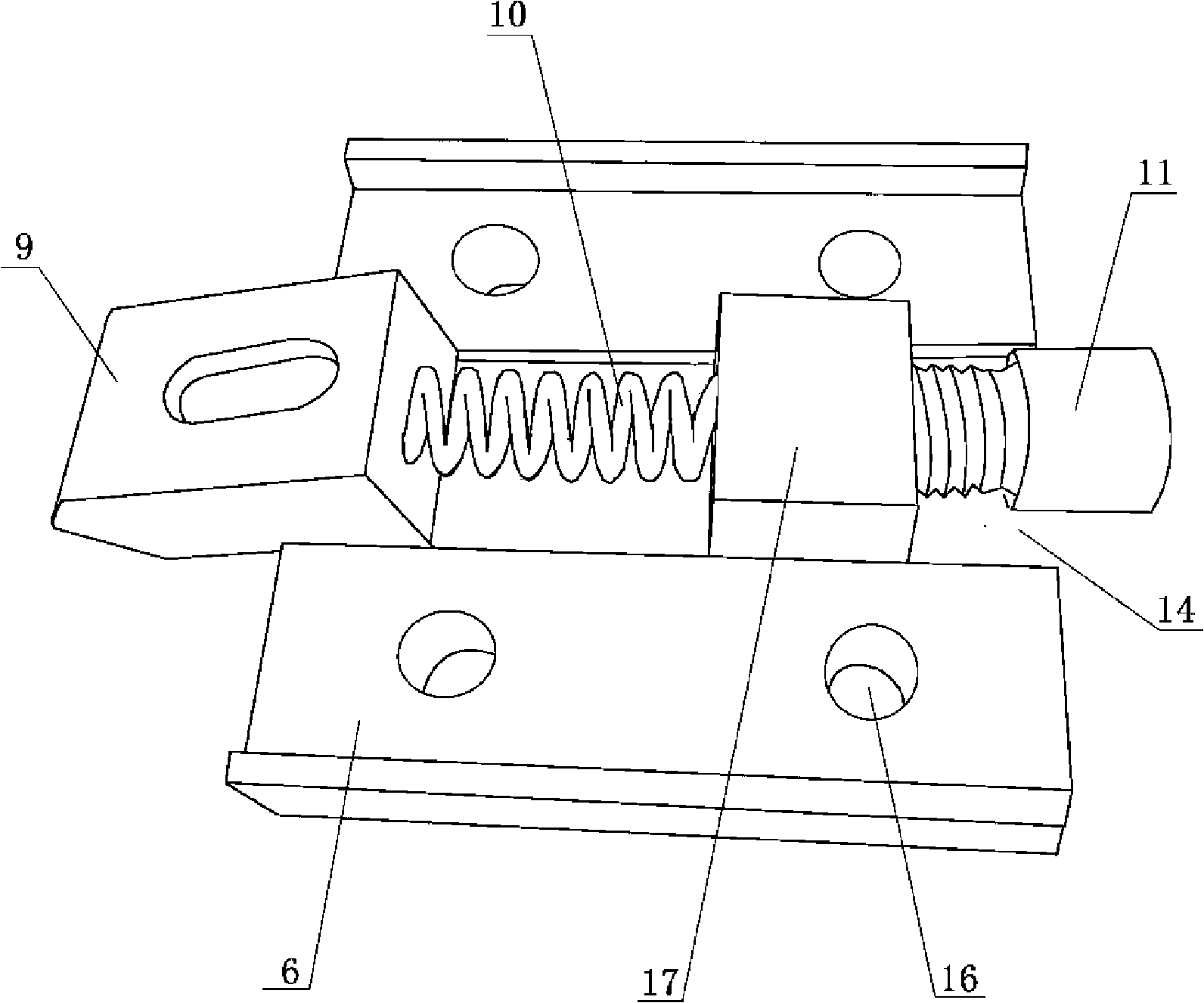

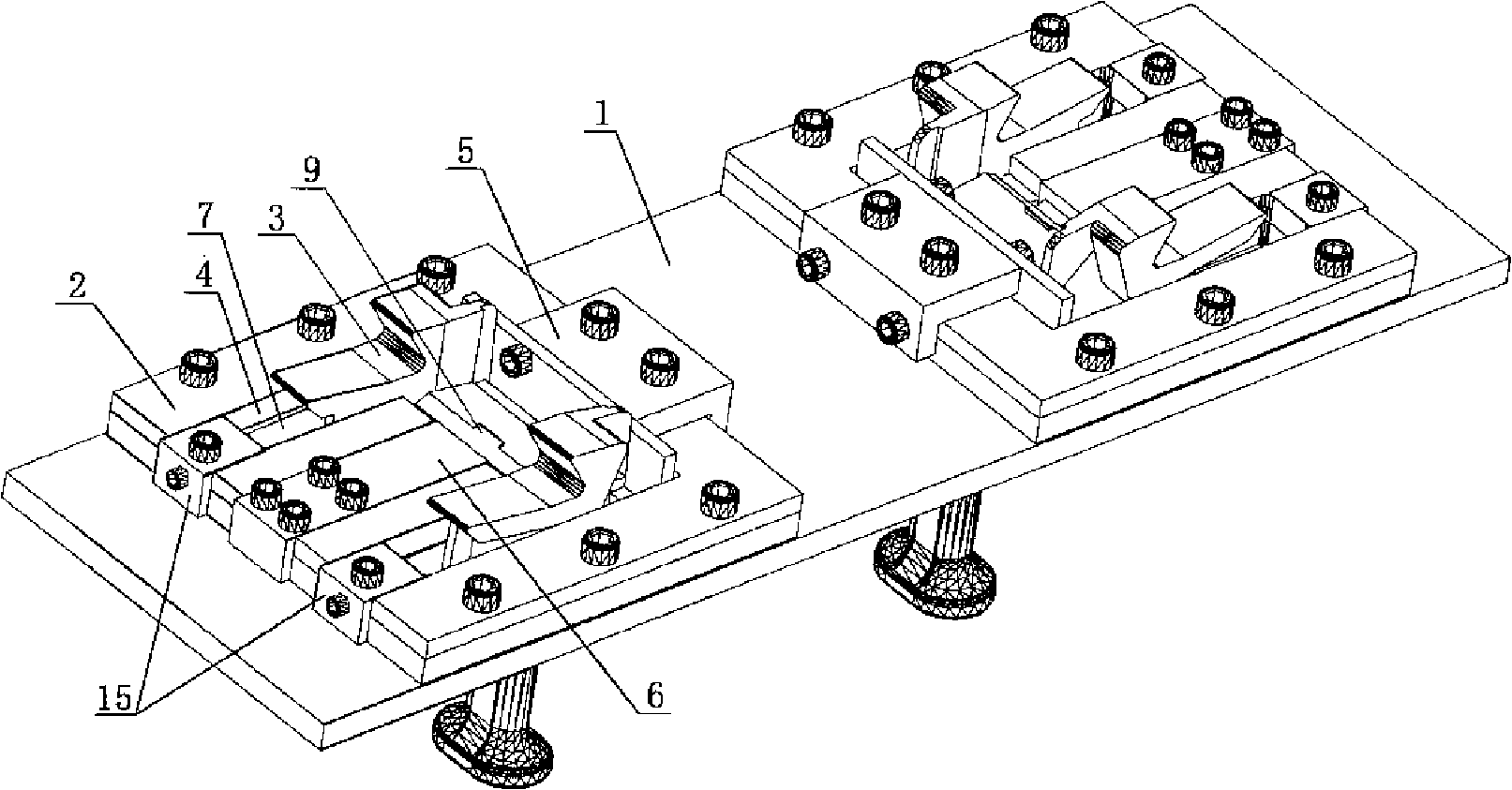

[0018] Examples see Figure 1-3 As shown in the figure, the positioning device of the fast clip fastener embedded part includes a positioning device fixing base plate 1 for fixing the fast clip fastener embedded part 3, see figure 1 The fixed bottom plate 1 of the positioning device is provided with a concave-shaped reserved hole 7 symmetrical to both sides of the rail 13, and a sealing rubber strip 4 is fixed around the hole wall of the concave-shaped reserved hole 7, and is fixed by the mold fixed pressure plate 2 and bolts 8. its fixed. The fast clip fastener embedded part 3 is positioned in the concave-shaped reserved hole 7, and its supporting legs are partially embedded in the concrete. see image 3 , the positioning device is fixed on the bottom plate 1, and the protruding part corresponding to the indentation of the concave-shaped reserved hole is used as the slideway 12, and the slideway 12 is built with a sliding tongue 9. The outer end of sliding depressing tongu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com