Permanent-magnetic vacuum on-load voltage-regulating tapping switch

A permanent magnet vacuum and tap changer technology, applied in electrical switches, electrical components, circuits, etc., can solve the problems of poor reliability of components, complicated switching process, limited volume reduction, etc. The effect of miniaturized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

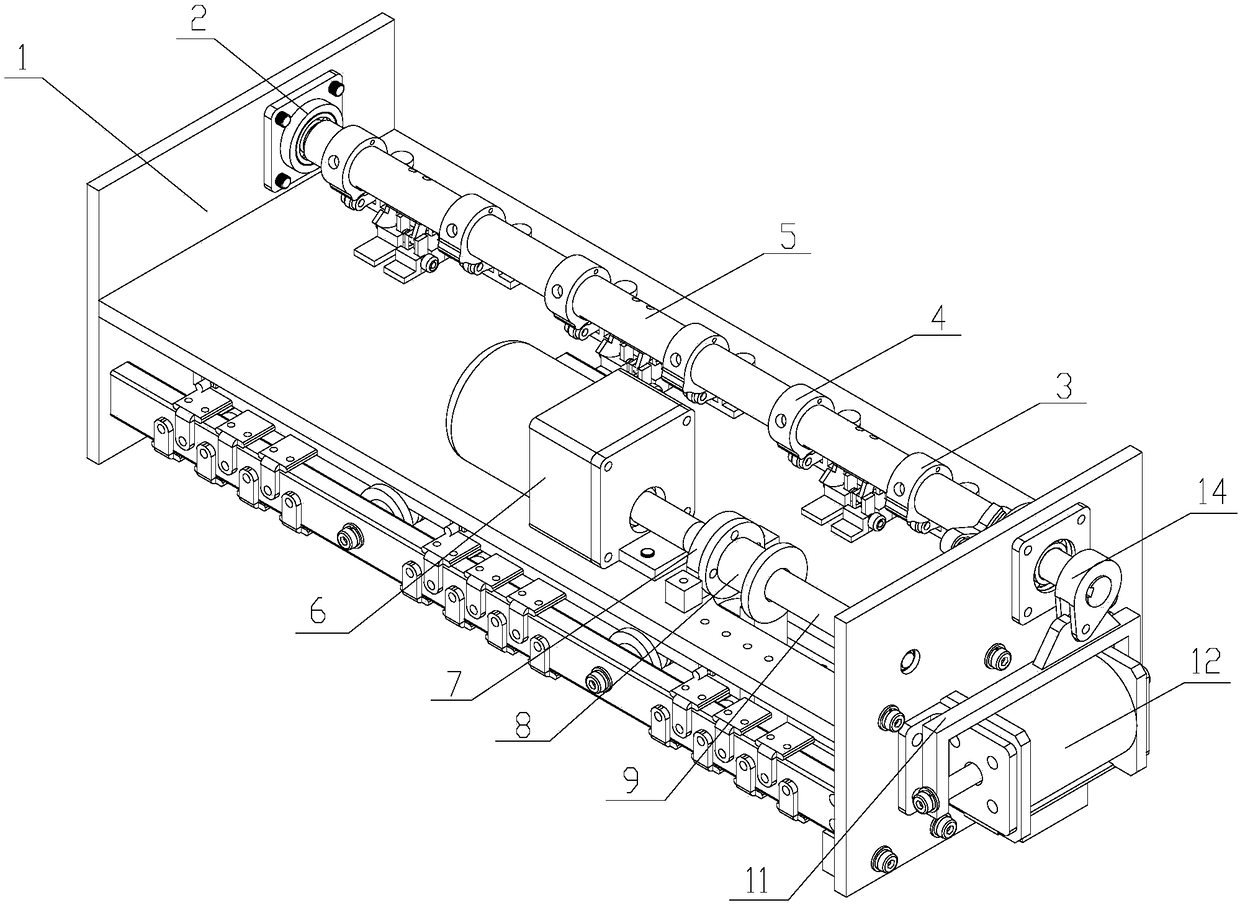

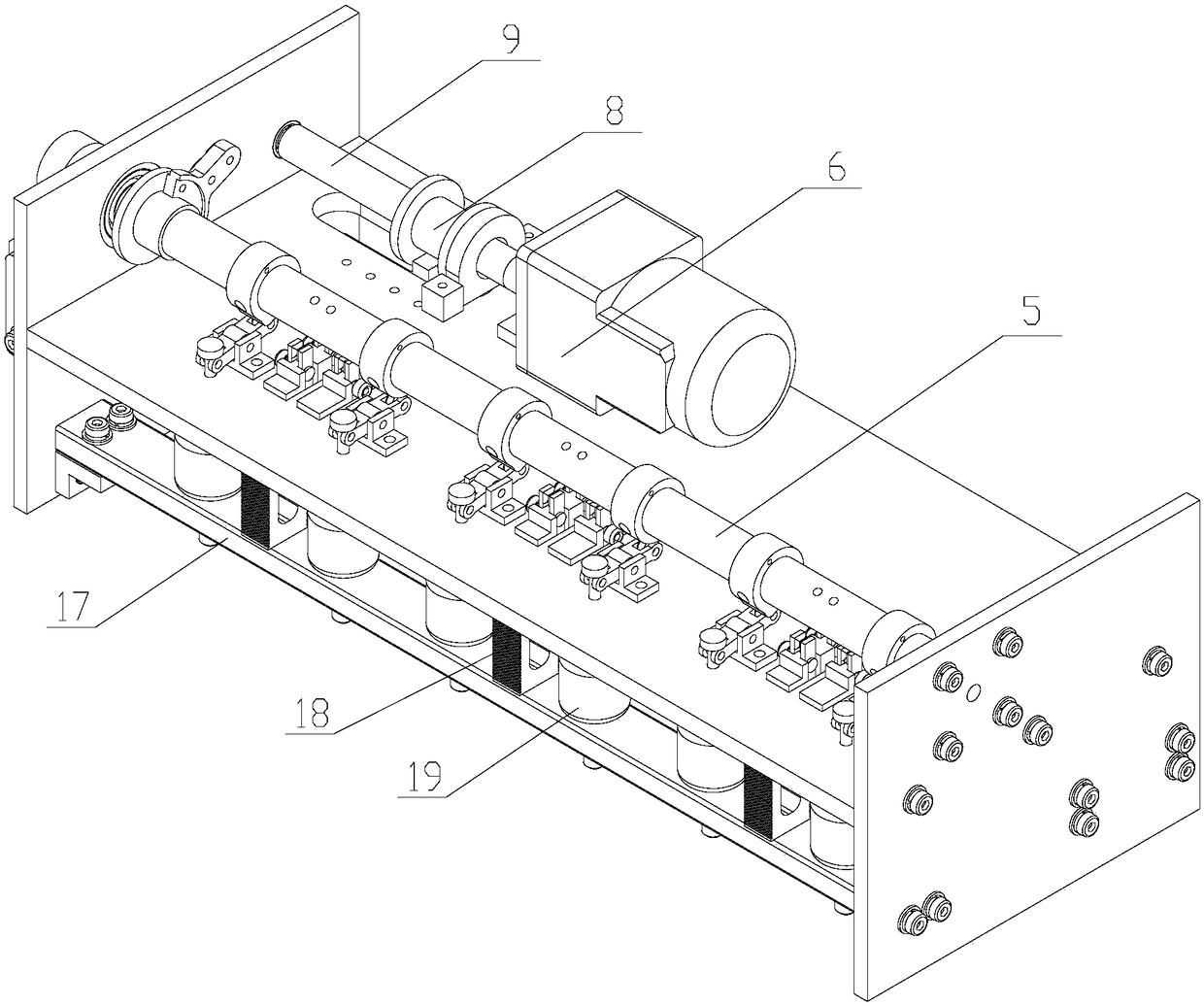

[0027] like figure 1 , Figure 3 to Figure 6 The shown permanent magnet vacuum on-load tap changer includes a gear selection mechanism and a circuit switching mechanism, and the gear selection mechanism is provided with a plurality of fixed contacts and a first movable contact 34 matched therewith; The circuit switching mechanism includes a permanent magnet mechanism 12, a switch, a vacuum tube 19 and a transition resistor 18; the gear selection mechanism and the circuit switching mechanism are arranged in parallel, and it is characterized in that: the switch includes a rotating shaft 5, a switching contact mechanism And the lever mechanism, the permanent magnet mechanism 12 drives the rotating shaft 5 to rotate, the rotating shaft 5 drives the lever mechanism to close or disconnect the vacuum tube 19, and the rotating shaft 5 drives the switching contact mechanism to move.

[0028] The rotating shaft 5 is provided with three groups of cams, each group of cams includes a firs...

Embodiment 2

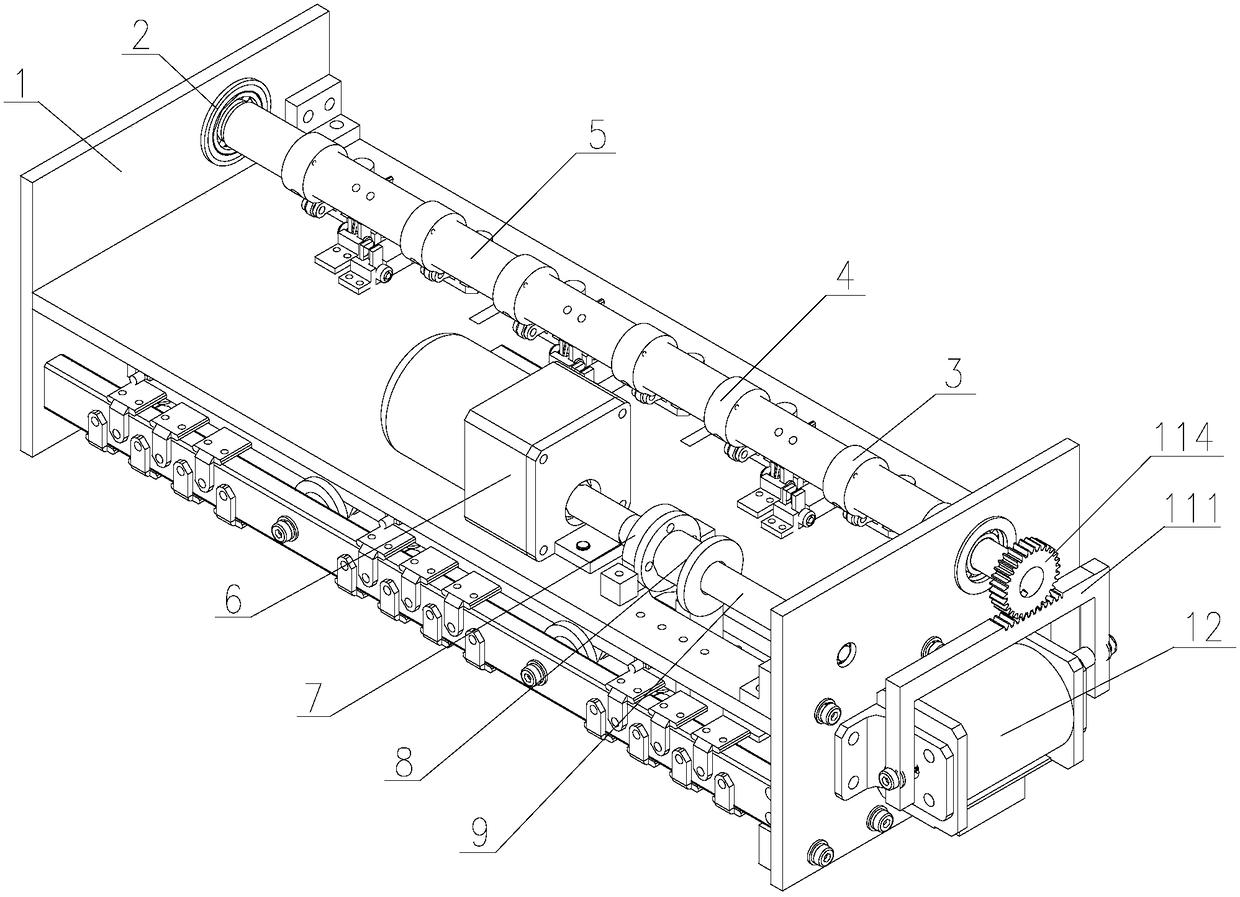

[0039] The difference between this embodiment and embodiment 1 is: as figure 2 As shown, the permanent magnet mechanism 12 is provided with a rack 111, and one end of the rotating shaft 5 is provided with a gear 114, the rack 111 meshes with the gear 114, and the rack 111 promotes the rotation of the gear 114 to drive the rotation of the rotating shaft 5 .

[0040] like Figure 7 As shown, after the present invention receives the voltage regulation instruction, the deceleration motor is started first, and the first movable contact is driven by the screw rod and the screw rod slider to select the gear position. After the gear position is selected, the motor stops, and then returns the signal Command the permanent magnet action, the shaft rotates through the first cam and the second cam so that one vacuum tube is switched from the open state to the closed state, and the other vacuum tube is switched from the closed state to the open state. During the rotation of the shaft, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com