Translation type umbrella workpiece automatic reversible table

A large workpiece, automatic flip technology, applied in the direction of electrical components, coil manufacturing, inductance/transformer/magnet manufacturing, etc., can solve the problems of stability, poor safety, low degree of automation, troublesome operation and other problems in the flipping process, and achieve a stable flipping process , high degree of automation and easy operation

Inactive Publication Date: 2010-12-01

HONGYANG MACHINERY FACTORY

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Medium and large workpieces need to be turned over during the processing process. The existing turning process of medium and large workpieces, especially medium and large cubic workpieces with high mass, is mostly completed by the hoisting and turning method of cables and truss trucks. The two ends are diagonally connected to the upper cable, and one end of the cable is fixed on the platform, and the other end of the cable is connected to the truss truck. The lifting force generated by the truss truck movement turns the right-angled platform 90 degrees. The whole process is subject to the truss truck movement. The overturning process is intermittent. This kind of overturning method not only requires manual installation of cables before overturning, but the operation is troublesome, and the overturning process has poor stability, safety, and low degree of automation.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

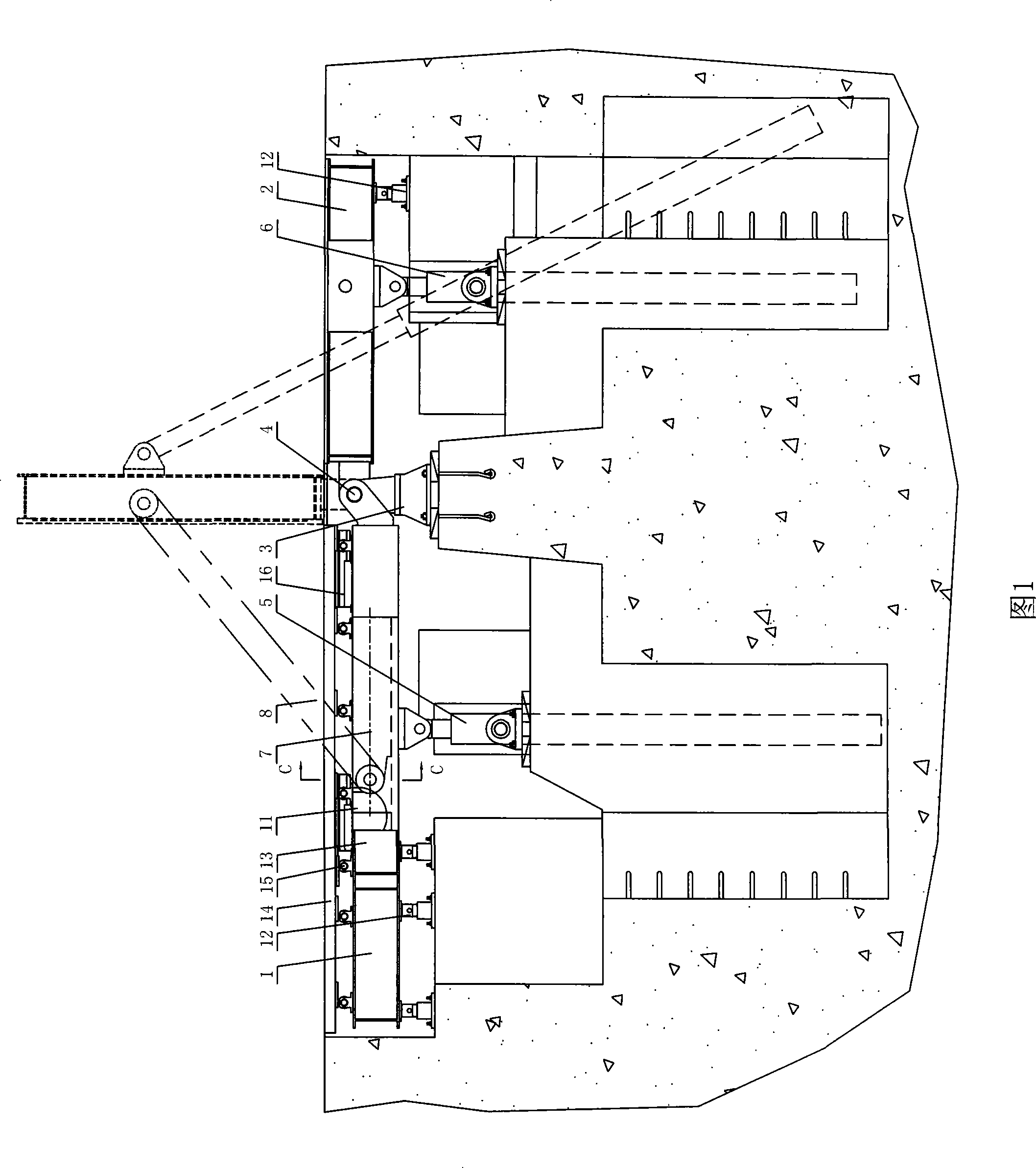

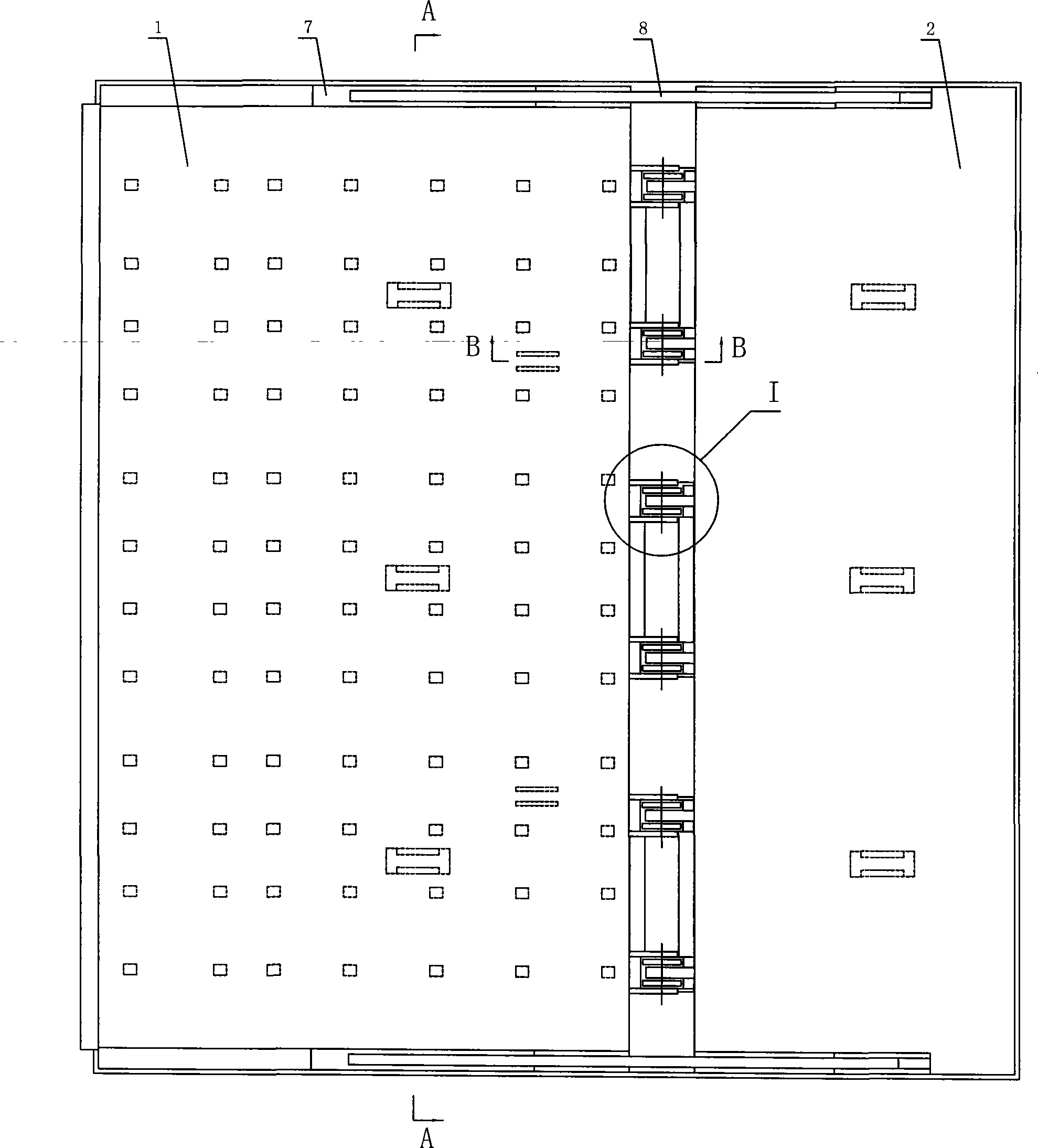

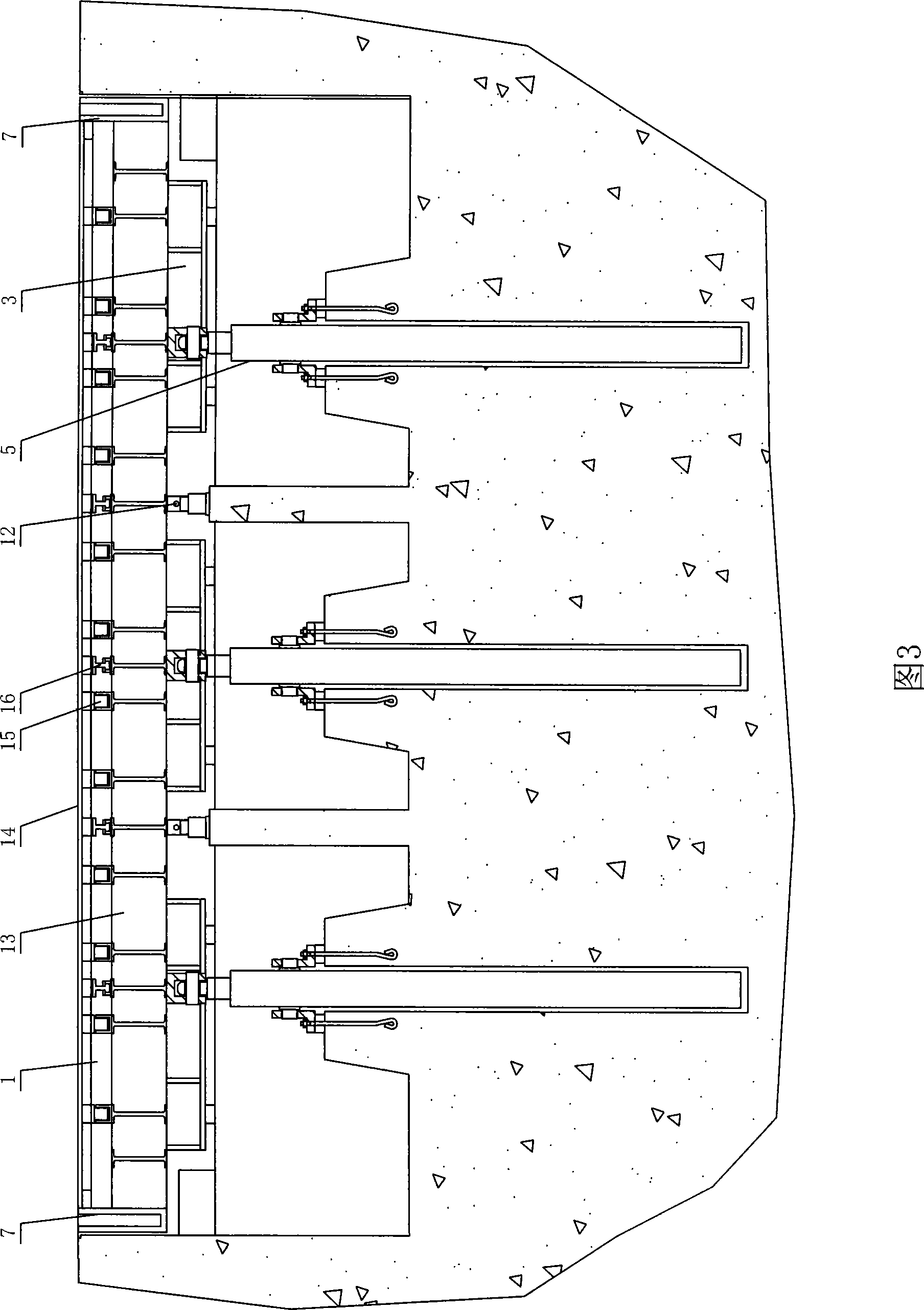

The invention relates to a translation type large workpiece automation tilting table for the turn of 90 degrees used in the large workpiece particularly to the middle and large cube workpiece, including a main platform and a side platform, the corresponding side of which is axially hinged with the hinge mount connected with the groundwork or the base; the lower part of the main platform is hingedwith the main lift cylinder, while the lower part of the side platform is hinged with a side lift cylinder. The cylinders of the main lift cylinder and the side lift cylinder are hinged with a fixed hinge mount, wherein a moving platform is arranged above the main platform. The invention has the beneficial effect in that: 1. the invention has high automation degree, convenient operation, which not only simplifies the producing technology, but also advances the production efficient; 2. the turning working procedure adopts the hydraulic pressure drive, the loading is large, the turn is stable with no impact, safety and reliability, and the main platform is arranged with the translation function, which ensures the workpiece tightly jointed with the side platform, ensures the turning procedure more stable; 3. the invention has simple structure and reasonable arrangement.

Description

Translational large workpiece automatic turning table technical field The invention relates to a translational large workpiece automatic turning table for turning medium and large workpieces, especially medium and large cubic workpieces by 90 degrees. Background technique Medium and large workpieces need to be turned over during the processing process. The existing turning process of medium and large workpieces, especially medium and large cubic workpieces with high mass, is mostly completed by the hoisting and turning method of cables and truss trucks. The two ends are diagonally connected to the upper cable, and one end of the cable is fixed on the platform, and the other end of the cable is connected to the truss truck. The lifting force generated by the truss truck movement turns the right-angled platform 90 degrees. The whole process is subject to the truss truck movement. Due to the limitation of the overturning process, the overturning process is intermittent. This ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01F41/06H01F41/02

Inventor 宋雁飞罗刚

Owner HONGYANG MACHINERY FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com