Method for preparing temperature sensitive intelligent anti-dip facing material and product thereof

A technology of temperature sensitivity and fabrics, applied in textiles and papermaking, etc., can solve the problems of airtightness, affecting work efficiency, poor comfort, etc., and achieves the effect of simple preparation method, reduced voids, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method (referred to as the preparation method) of the temperature-sensitive intelligent anti-soaking fabric (abbreviated as the anti-soaking fabric) designed by the present invention comprises the following steps:

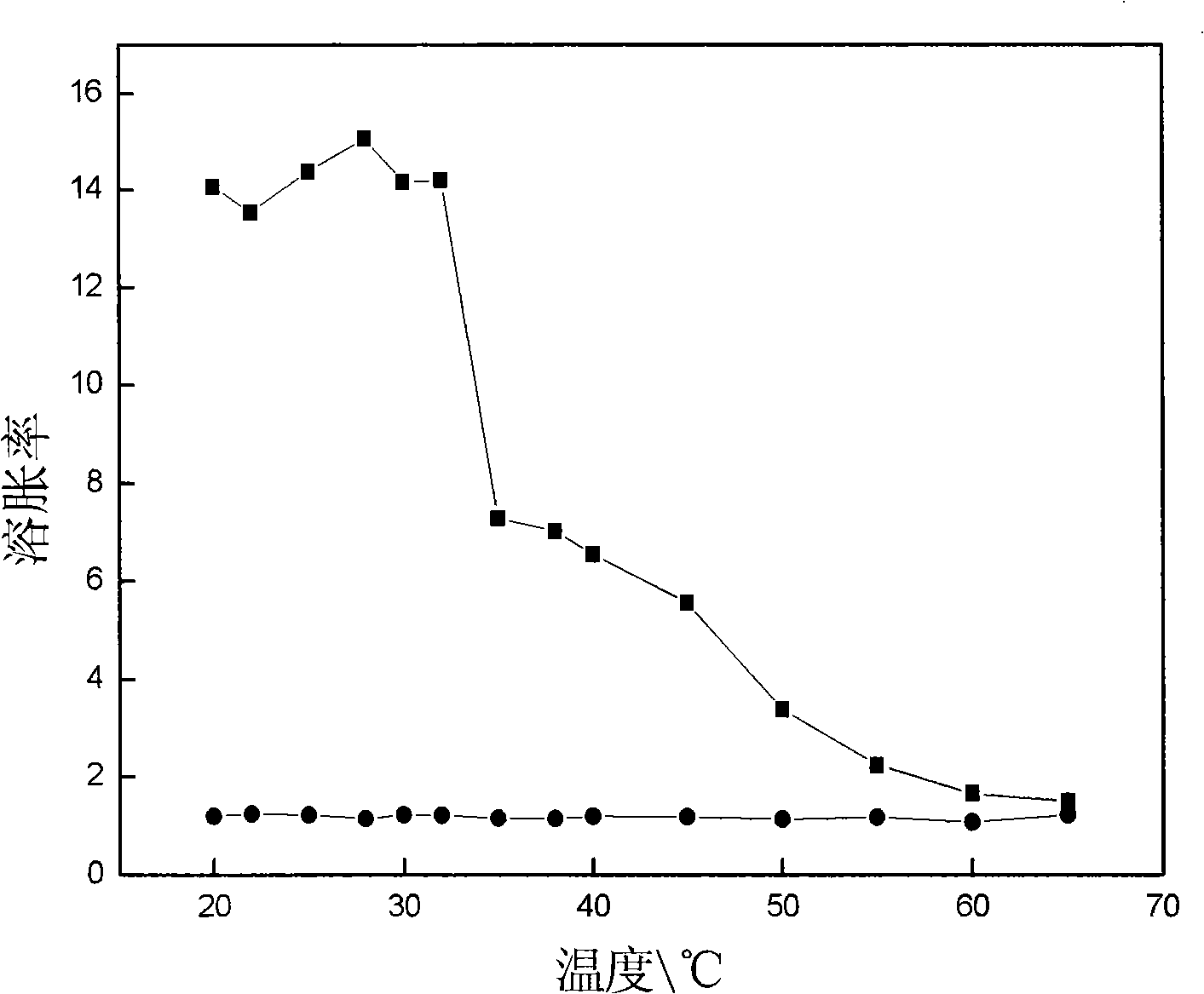

[0019] 1. Synthetic temperature-sensitive N-tert-butylacrylamide and acrylamide copolymer; adopt the N-tert-butylacrylamide and acrylamide that feed molar ratio is 60~40: 40~60 (preferably 50:50) in Free radical polymerization occurs in methanol with ammonium persulfate or azobisisobutyronitrile (preferably ammonium persulfate) as the initiator; the reacted mixed solution is vigorously stirred, and the copolymer is precipitated with acetone and dissolved 3-5 times Precipitation gave a pure, white solid of N-tert-butylacrylamide and acrylamide copolymer. The aqueous solution of the obtained copolymer is temperature sensitive, and can be dissolved in water at a certain temperature, and it will not dissolve at a temperature higher than this temp...

Embodiment 1

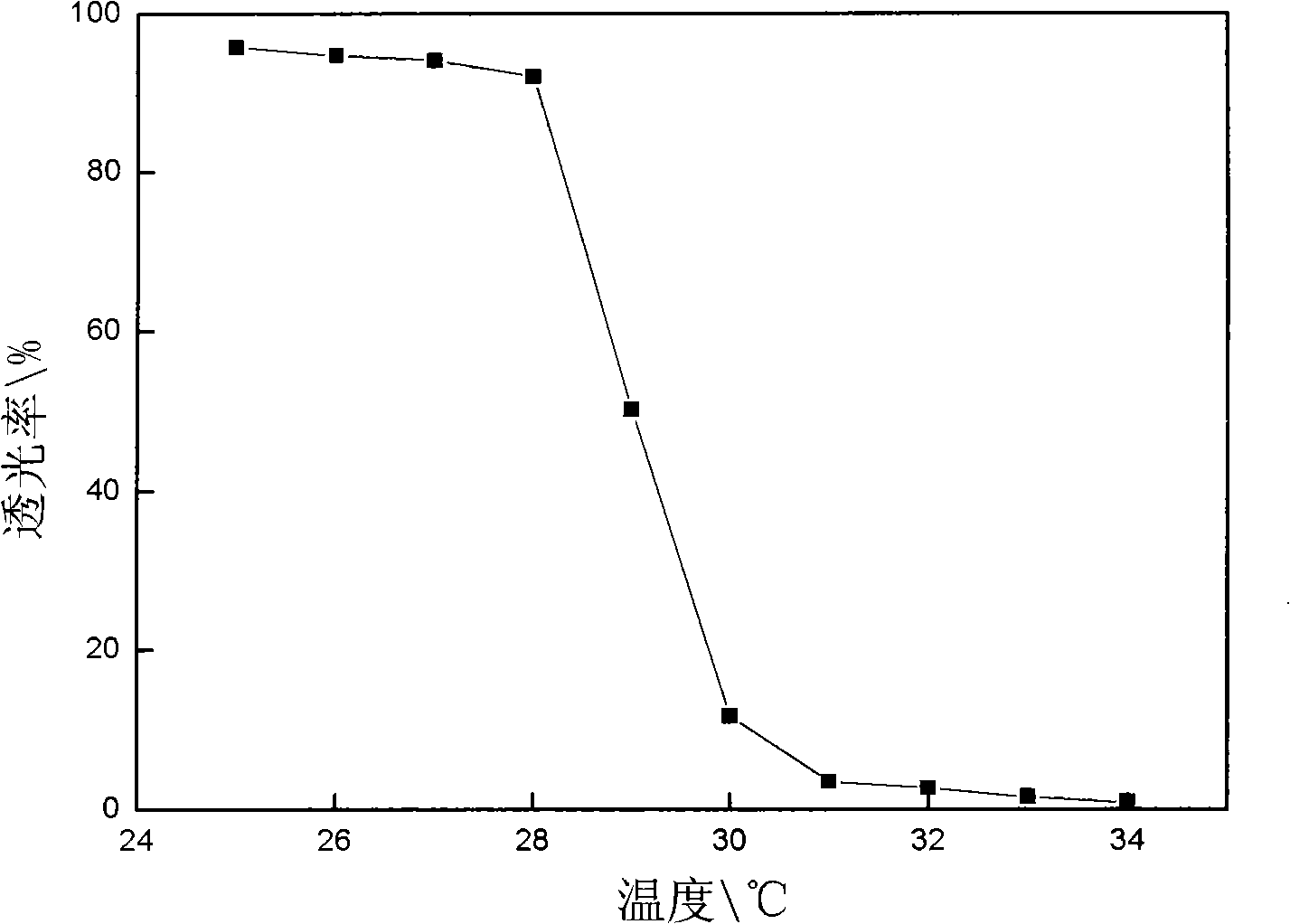

[0028] 1. Synthesis of temperature-sensitive N-tert-butylacrylamide and acrylamide copolymer; N-tert-butylacrylamide and acrylamide with a feed molar ratio of 50:50 are used in methanol to generate ammonium persulfate as an initiator Free radical polymerization reaction; the reacted mixed solution was vigorously stirred, and the copolymer was precipitated with acetone, and dissolved and precipitated 5 times to obtain pure, white solid N-tert-butylacrylamide and acrylamide copolymer. Gained copolymer adopts spectrophotometry to measure its LCST to be 28.2 ℃ (referring to figure 1 ).

[0029] 2. Preparation of coating liquid: 8% (mass, the same below) of the copolymer obtained in the first step, 2.3% of the crosslinking agent BTCA and 2.2% of the catalyst SHP are formulated into an aqueous solution, stirred and put into the refrigerator for defoaming At least 24 hours, and make it further dissolve and mix, during which it can be stirred frequently to speed up the dissolution an...

Embodiment 2

[0033]1. Synthetic temperature-sensitive N-tert-butylacrylamide and acrylamide copolymer; adopting a feed molar ratio of N-tert-butylacrylamide and acrylamide in methanol with azobisisobutyronitrile as 40: 60 The initiator undergoes a free radical polymerization reaction; the reacted mixed solution is vigorously stirred, and the copolymer is precipitated with acetone, and after 4 times of dissolution and precipitation, a pure, white solid N-tert-butylacrylamide and acrylamide copolymer are obtained. The LCST of the obtained copolymer measured by spectrophotometry was 39.0°C.

[0034] 2. prepare coating liquid: the multipolymer of 15% (mass, the same below) the 1st step gained, the cross-linking agent BTCA of 5.0% and the catalyst SHP of 2.5% are formulated into the mixed homogeneous aqueous solution, all the other are the same as embodiment 1.

[0035] 3. Fabric coating: Coat the pre-treated pure cotton fabric twice with the coating solution prepared in step 2, and dry the fab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com