Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54 results about "Tert-butylacrylamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

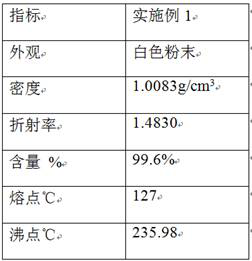

N-tert-Butylacrylamide 97% CAS Number 107-58-4. Linear Formula CH 2 =CHCONHC(CH 3) 3. Molecular Weight 127.18 . Beilstein Registry Number 1742331 . EC Number 203-505-6. MDL number MFCD00026271. PubChem Substance ID 24865764

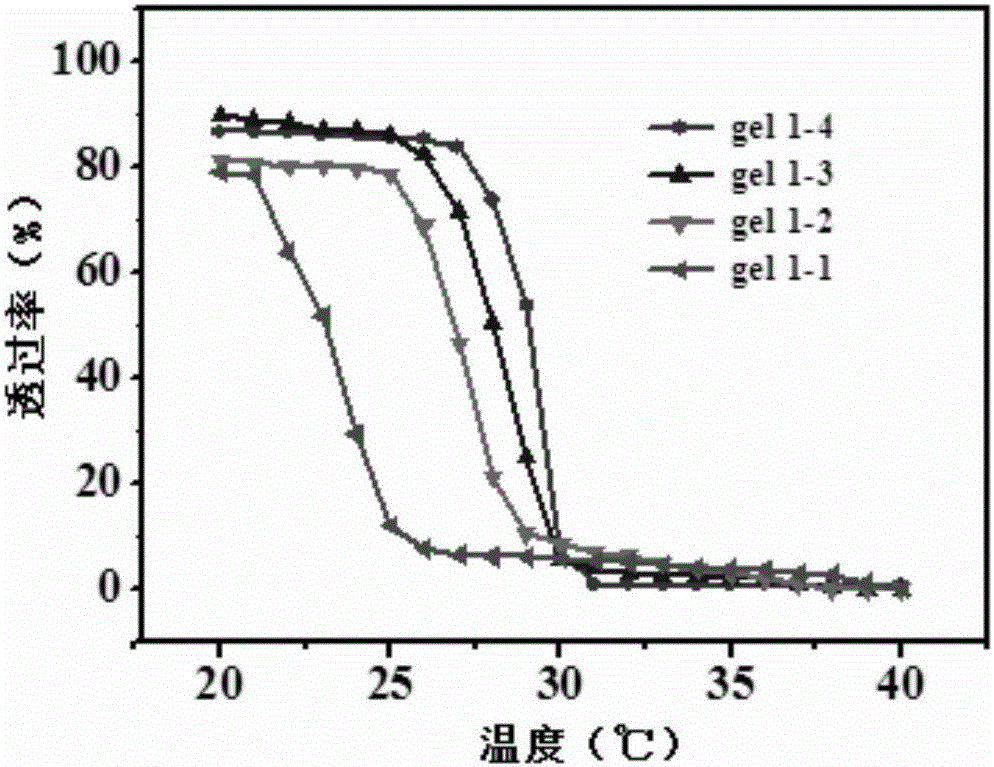

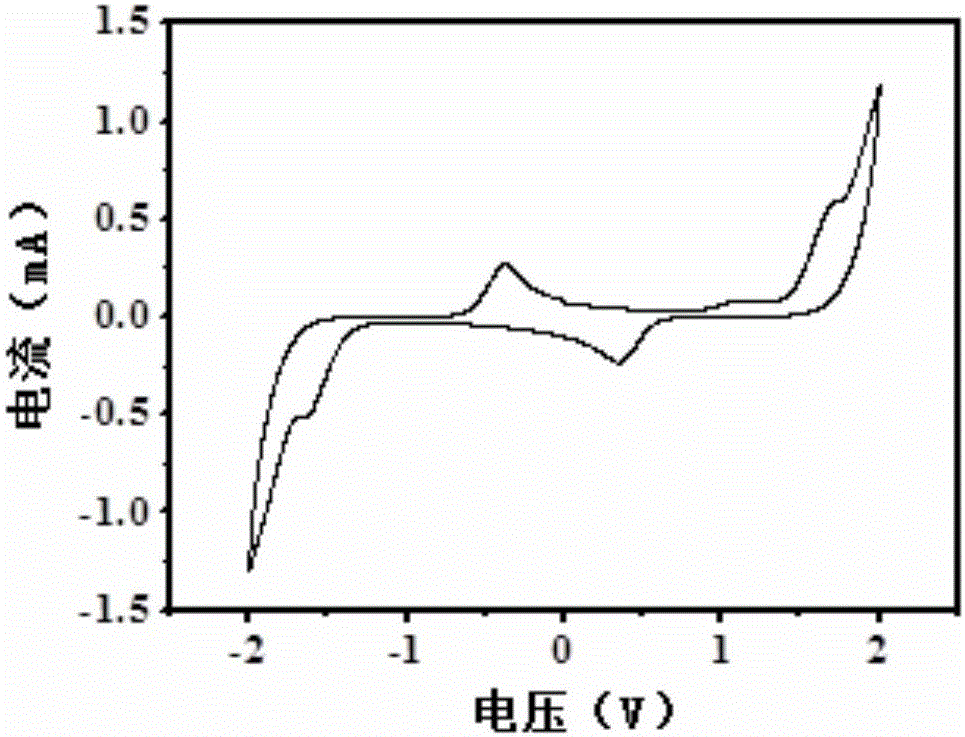

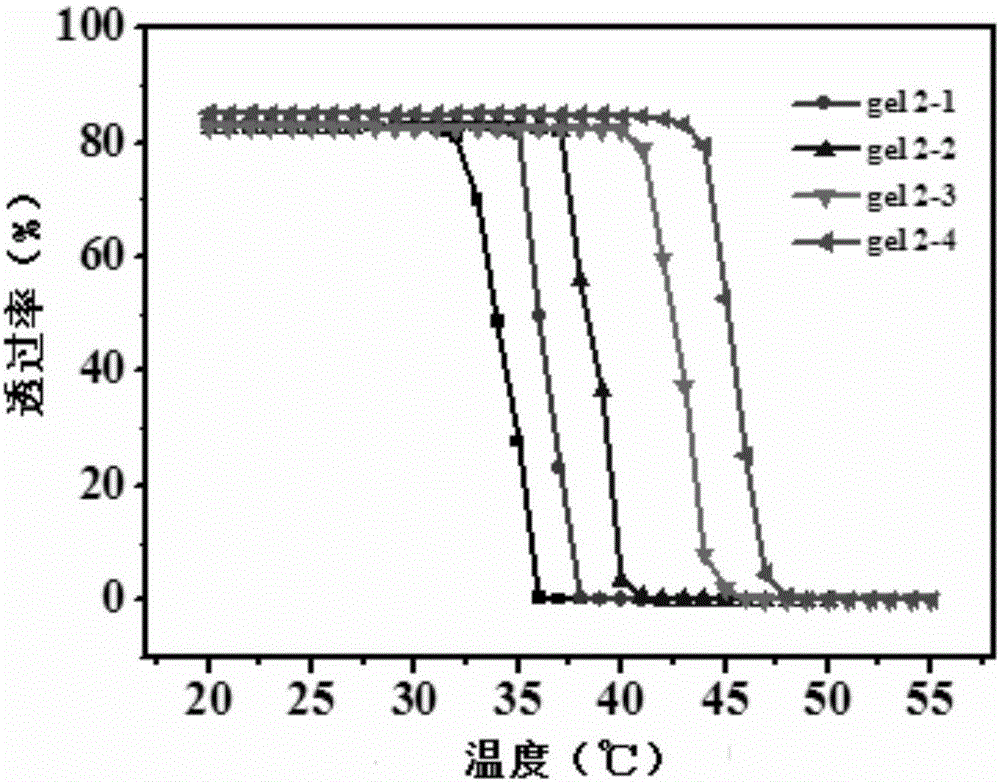

Heat/electric responding gel color changing glass material

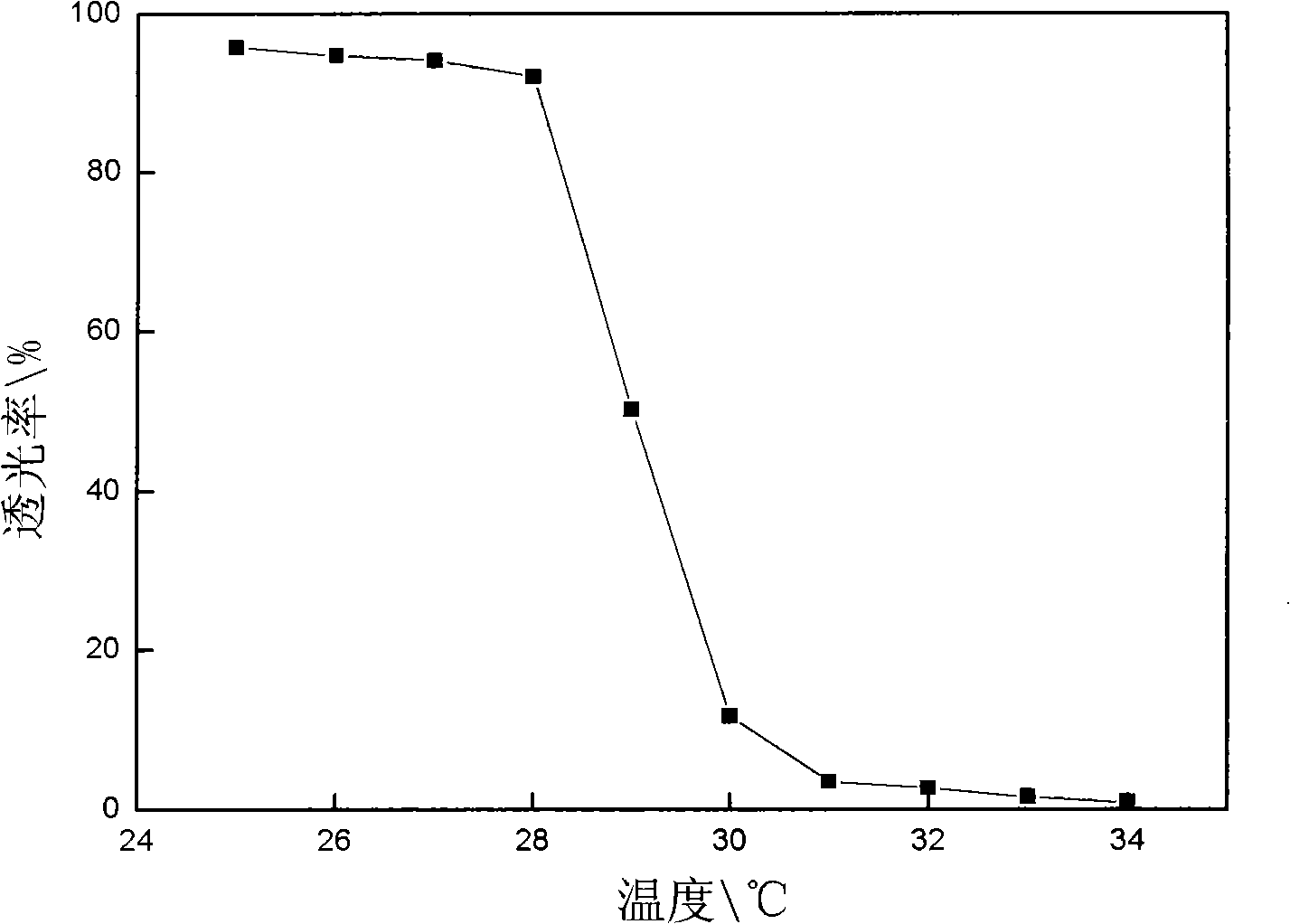

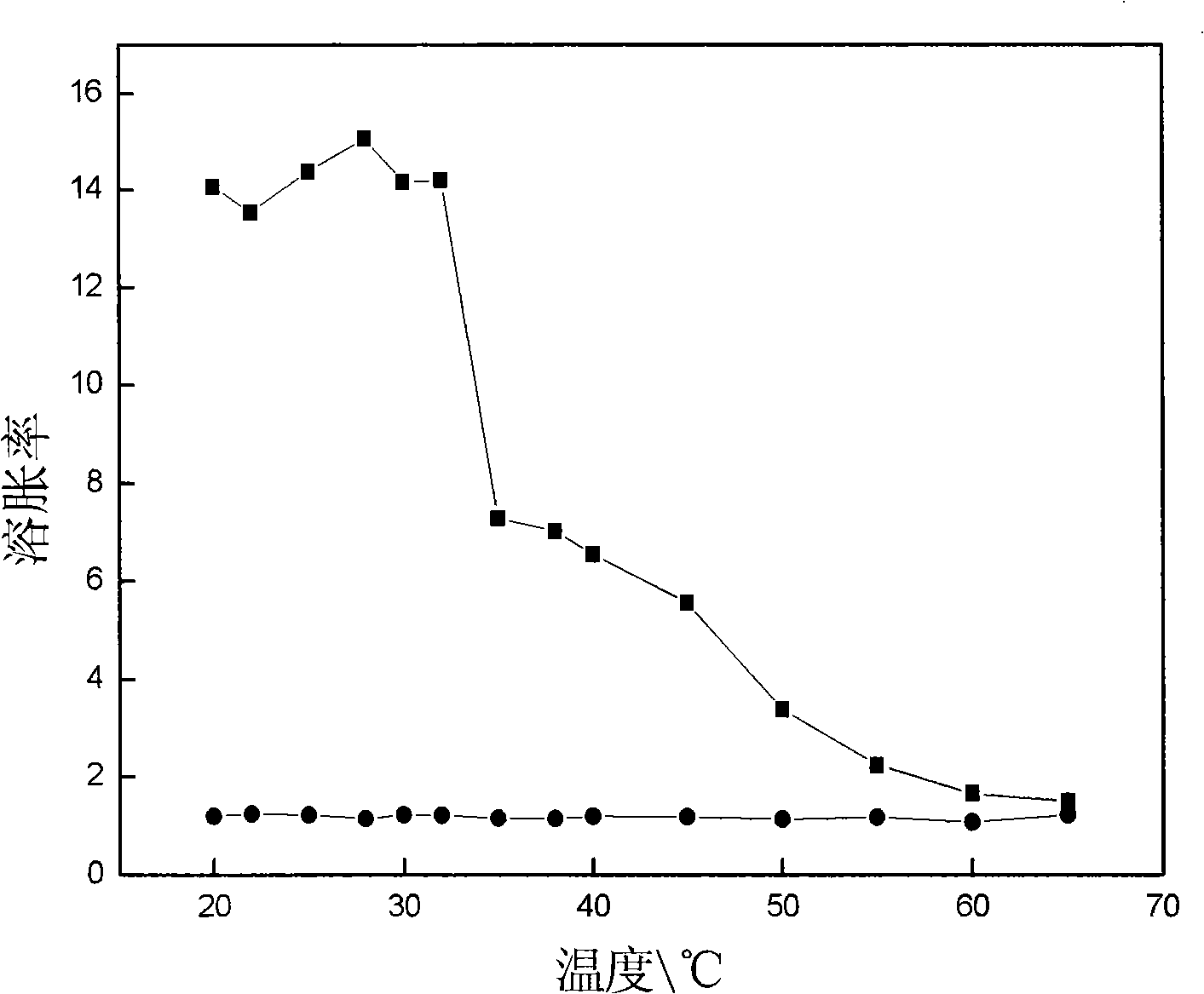

ActiveCN106188388AHigh temperature controllabilityImprove stabilityChemical structureStructural formula

The invention relates to a heat / electric responding hydrogel color changing glass material based on ionic liquid modification. The material is obtained by dissolving a heat responding monomer, an ionic liquid, a crosslinking agent, an initiator, and a catalyst into water to carry out polymerization; wherein the heat responding monomer is a mixture composed one or more of N-isopropyl acrylamide, N-tert-butyl acrylamide, and N-vinyl caprolactam. The chemical structural formula of the ionic liquid is shown in the description, in the formula, R1, R2, and R3 independently represent a C1-C8 alkyl group, and X<-> represents Cl<->, Br<->, I<->, NO3<->, SO4<2->, PO4<3->, or OH<->. The crosslinking agent is divinyl purpurine derivatives. Through the technical scheme mentioned above, a heat / electric responding hydrogel color changing glass material can be obtained; the responding property to the change of environmental conditions is enhanced, and the temperature controllability, stability, and service life of color changing devices are all improved.

Owner:SUZHOU UNIV

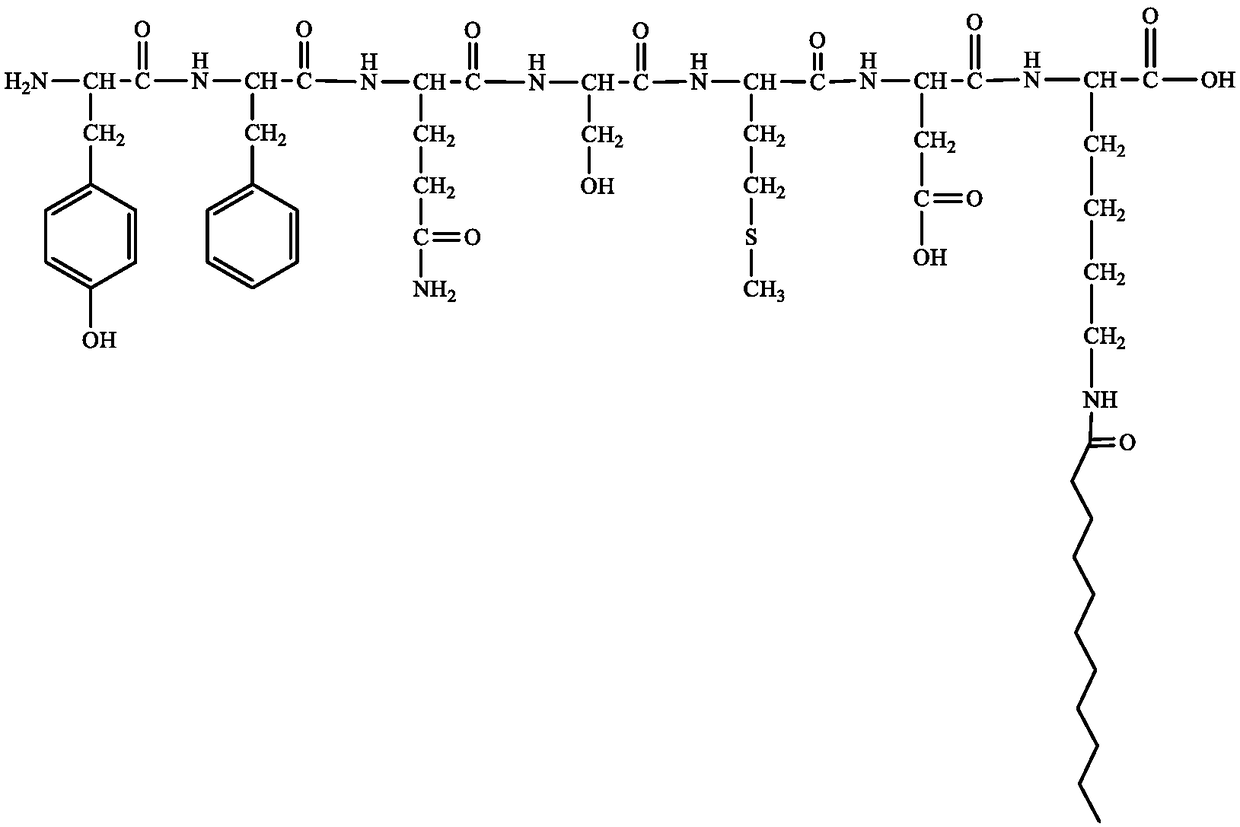

Preparation method, product and application of molecularly imprinted polymer

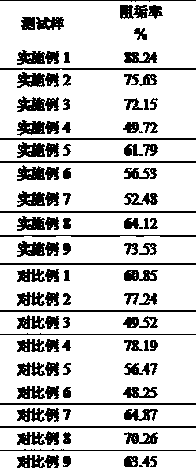

ActiveCN108409908AHigh selectivityAchieve targetedOther chemical processesPharmaceutical non-active ingredientsSolventTert butyl

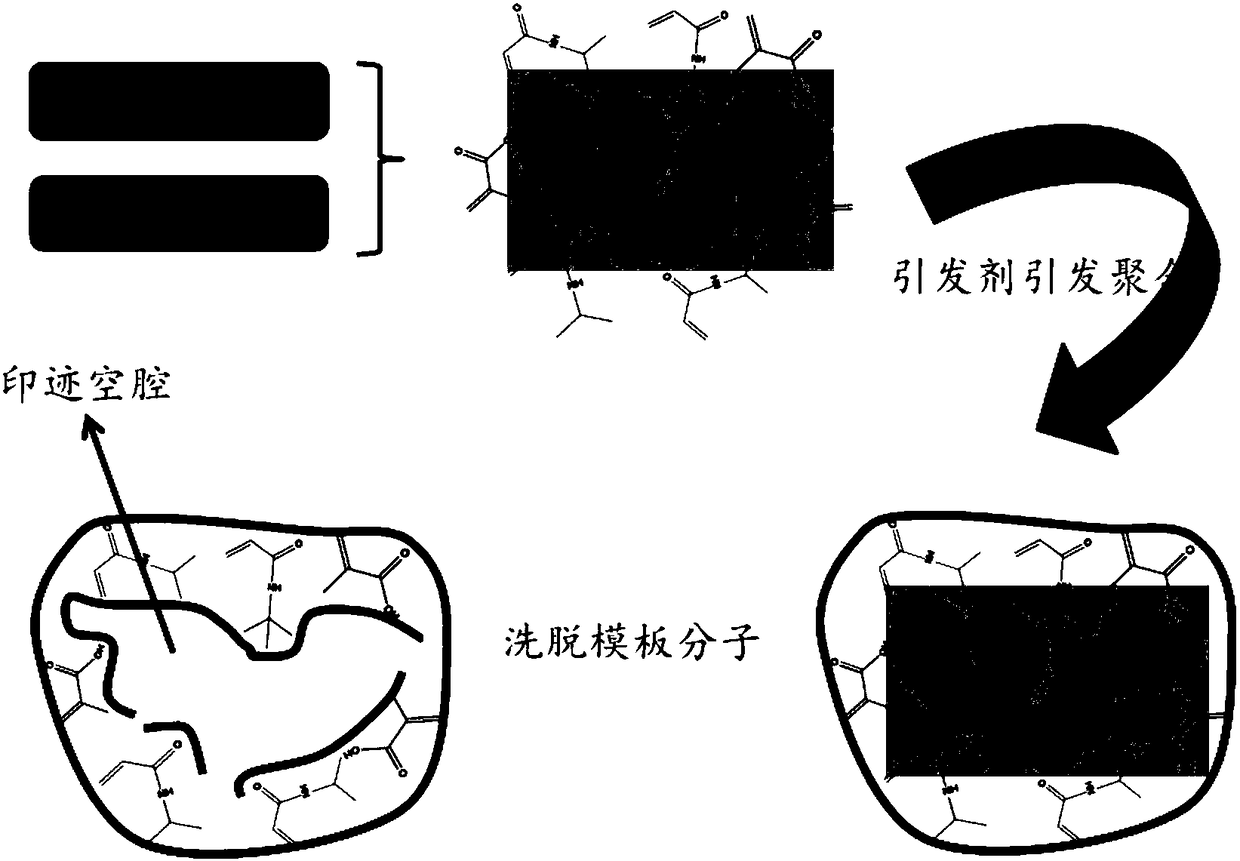

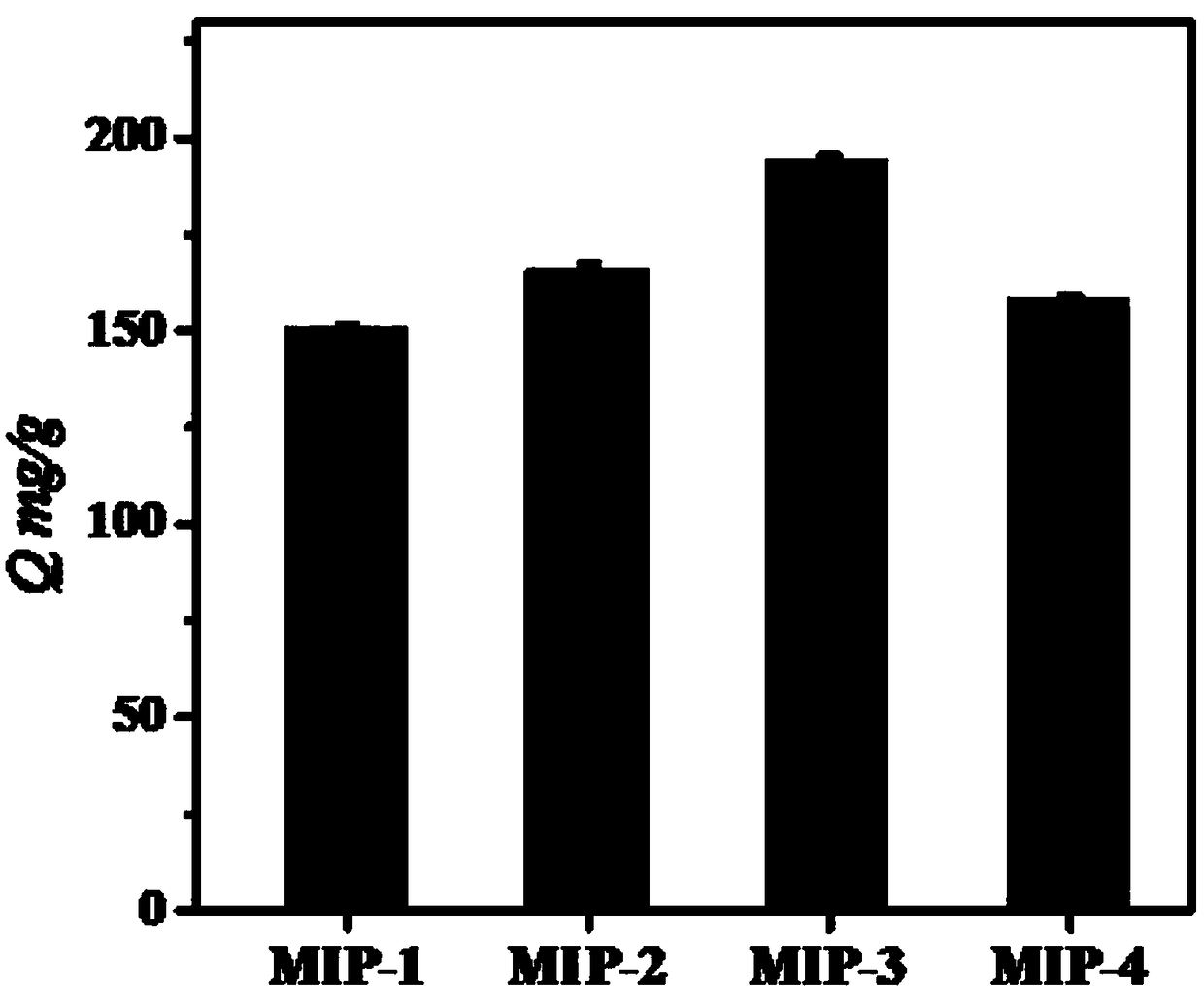

The invention provides a preparation method, a product and an application of a molecularly imprinted polymer. The preparation method of the molecularly imprinted polymer mainly includes the steps: performing interaction on yfqsmdk-C10 short peptides serving as template molecules with methacrylic acid, N-isopropylacrylamide, N, N-dimethyl bisacrylamide and N-n-tert-butyl acrylamide by non-covalentbonds (such as hydrogen bonds and Van der Waals force); adding an appropriate quantity of initiators to perform polymerization reaction, and imprinting the surface of the polymer with short peptide molecules; eluting the short peptide molecules imprinted on the surface by proper solvents (namely, extraction agents) after polymerization reaction to reserve a cavity capable of specifically recognizing the short peptide molecules. As the short peptide molecules are highly expressed on the surface of a tumor, after the short peptides are eluted, the formed cavity can specifically recognize the short peptide molecules highly expressed on the surface of the tumor, and selectivity and targeting ability of the molecularly imprinted polymer for tumor cells are finally realized.

Owner:刘飞

Method for preparing temperature sensitive intelligent anti-dip facing material and product thereof

InactiveCN101302718ATemperature-sensitive intelligenceReduce voidsTextiles and paperCarboxylic acidTert butyl

Owner:TIANJIN POLYTECHNIC UNIV

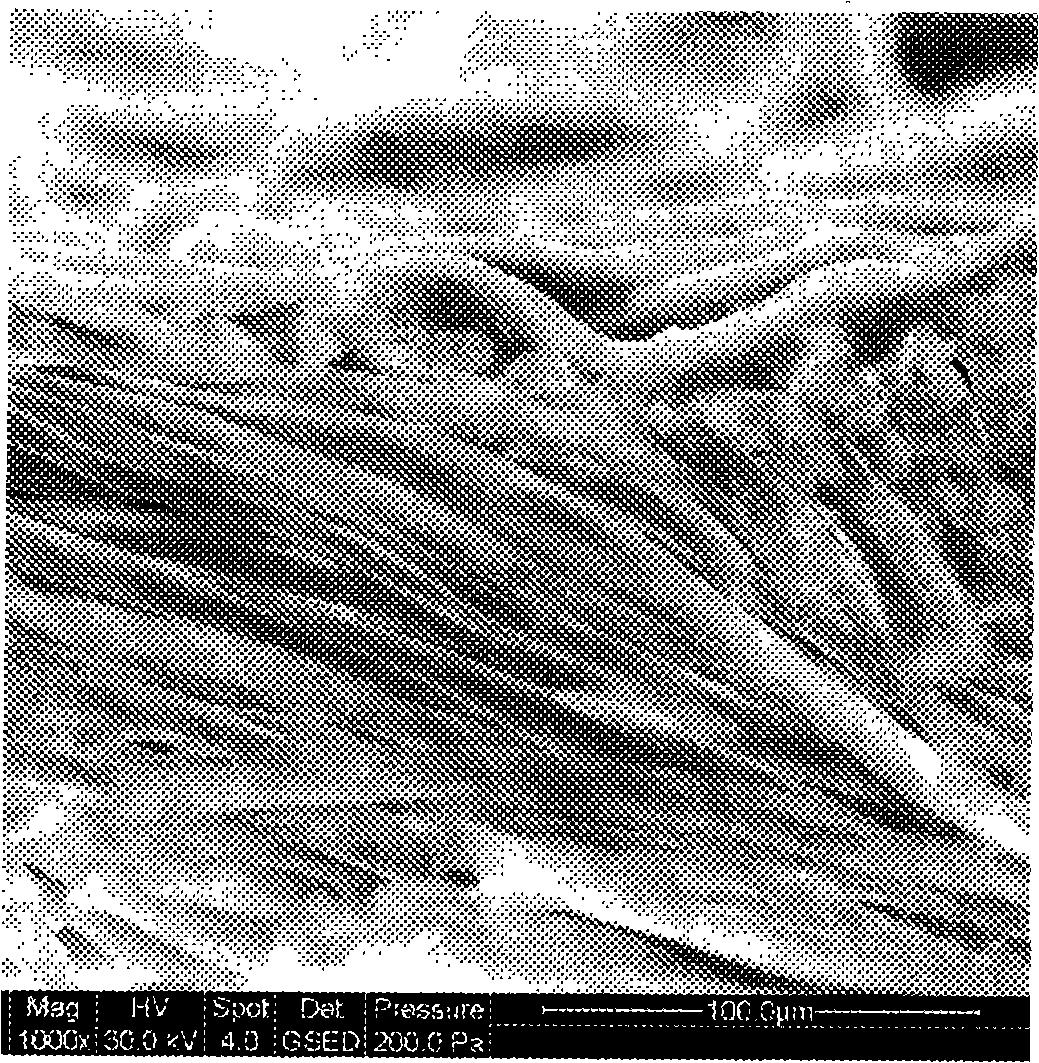

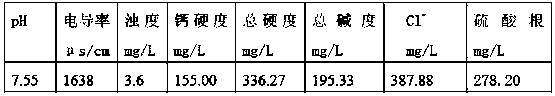

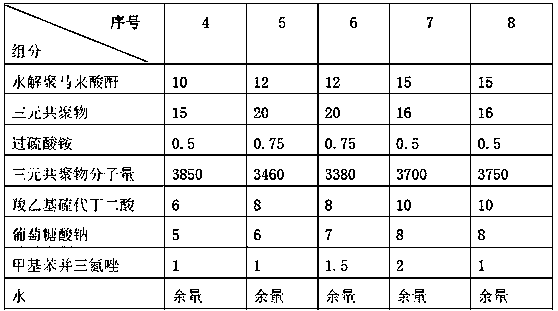

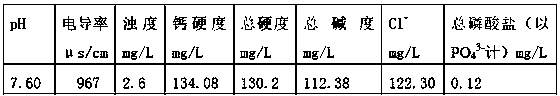

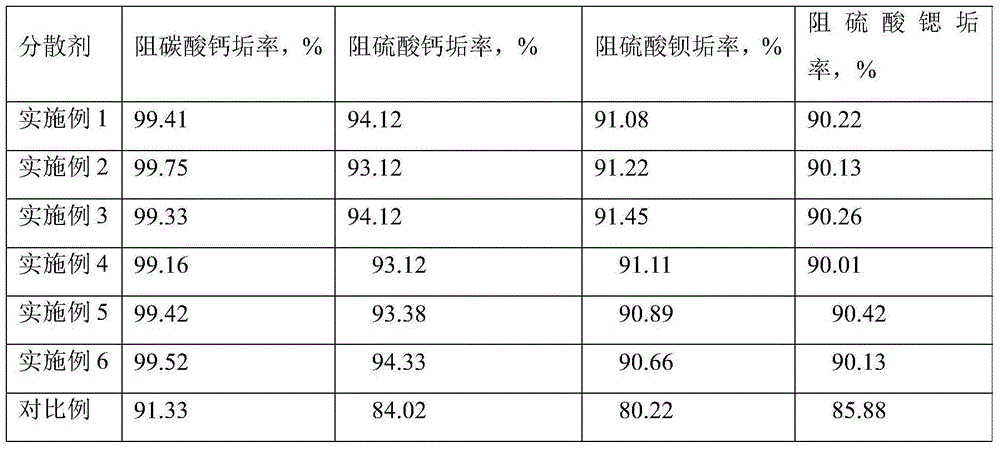

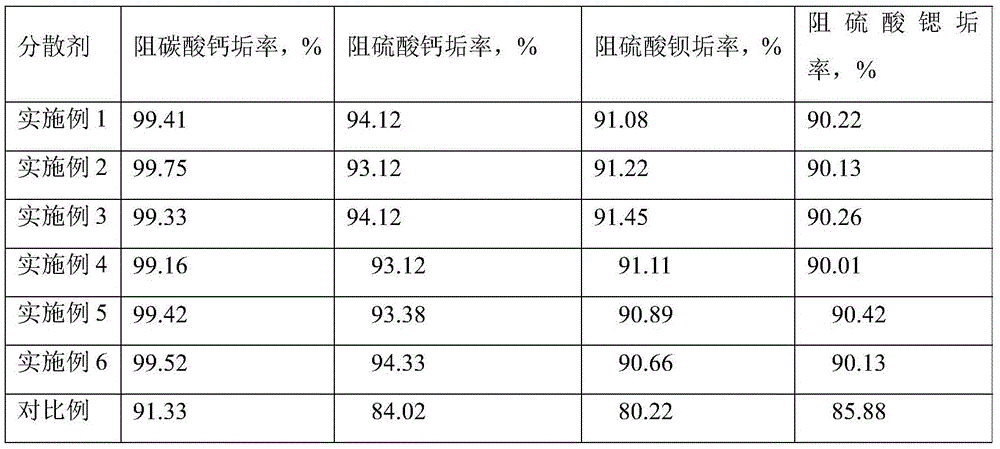

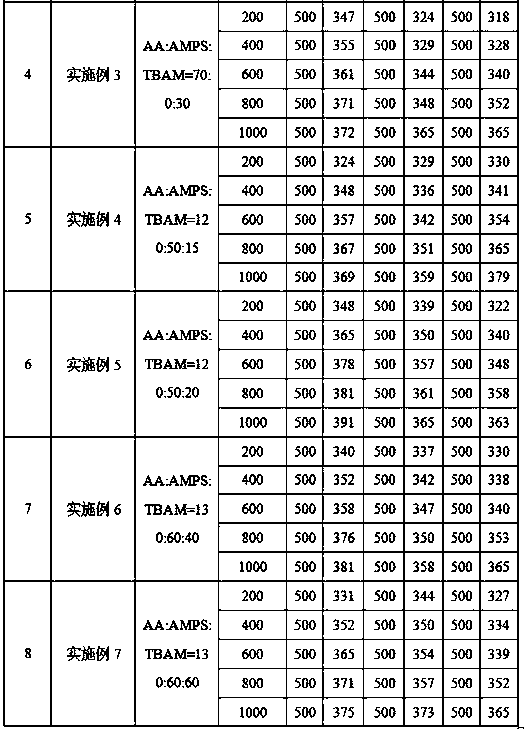

Environmentally-friendly scale and corrosion inhibitor and preparation method thereof

PendingCN109052675AGood scale and corrosion inhibitionGood anti-scaling and dispersing effectSpecific water treatment objectivesScale removal and water softeningGluconic acidTert butyl

The invention discloses an environmentally-friendly scale and corrosion inhibitor and a preparation method thereof. The environmentally-friendly scale and corrosion inhibitor comprises the following ingredients in parts by weight relative to the total mass of scale and corrosion inhibitor: 10-15% of hydrolytic polymaleic anhydride, 14-20% of acrylic acid / 2-acrylamide-2-methyl propanesulfonic acid / n-tert-butyl acrylamide terpolymer, 0.5-1% of ammonium persulfate, 5-10% of carboxyalkylthiosuccinic acid, 5-8% of sodium gluconate, 1-2% of methylbenzotriazole and the balance of deionized water. The scale and corrosion inhibitor has the advantages of no phosphorus or zinc, environment protection and excellent scale and corrosion inhibition effect.

Owner:CHANGZHOU KEWEI TIANSHI ENVIRONMENTAL TECH

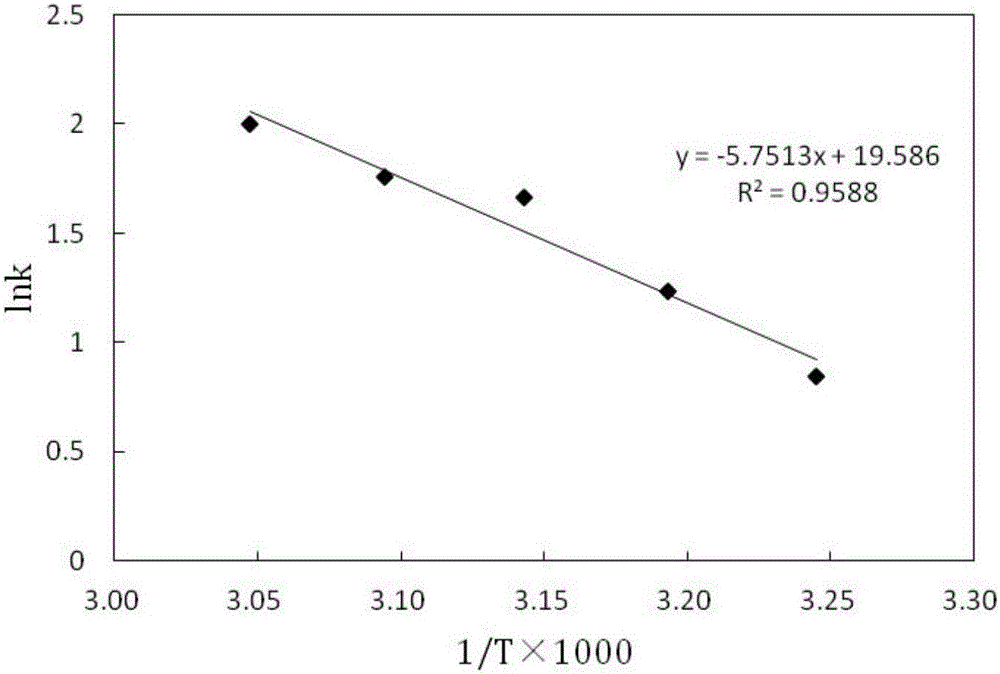

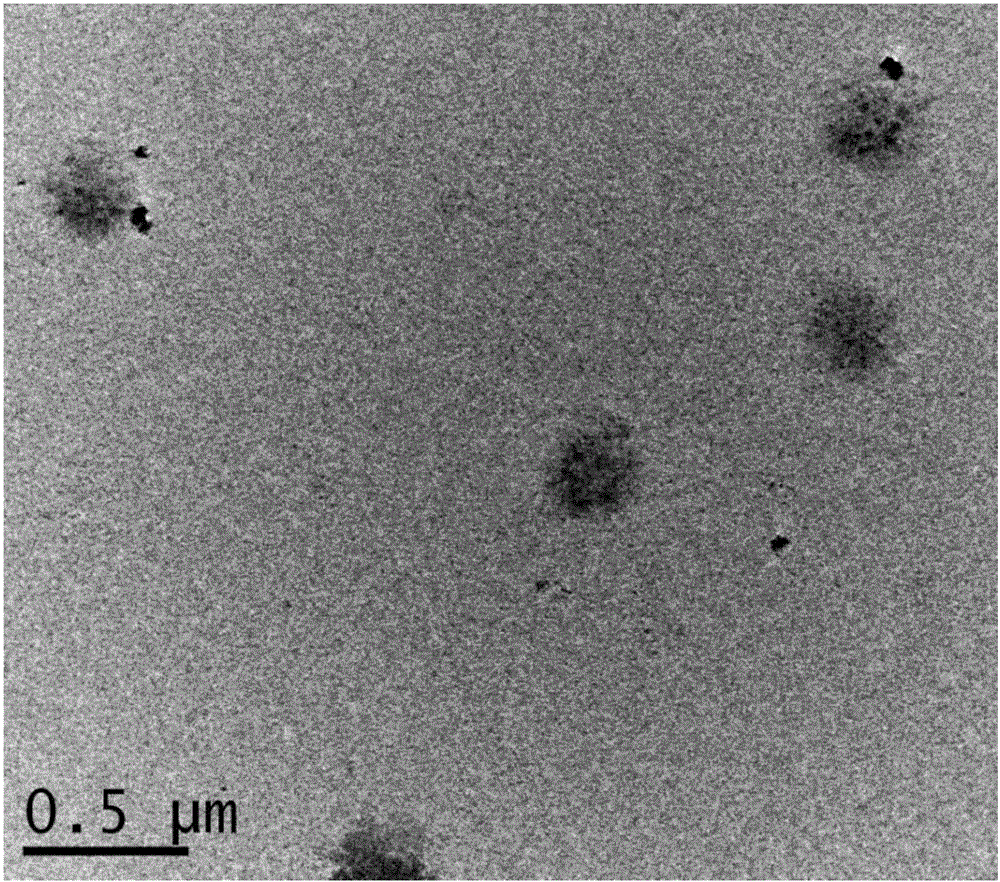

Preparation method of difunctional copolymerized nanoparticle inhibitor and application thereof in inhibition and detoxification of amyloid beta protein aggregation

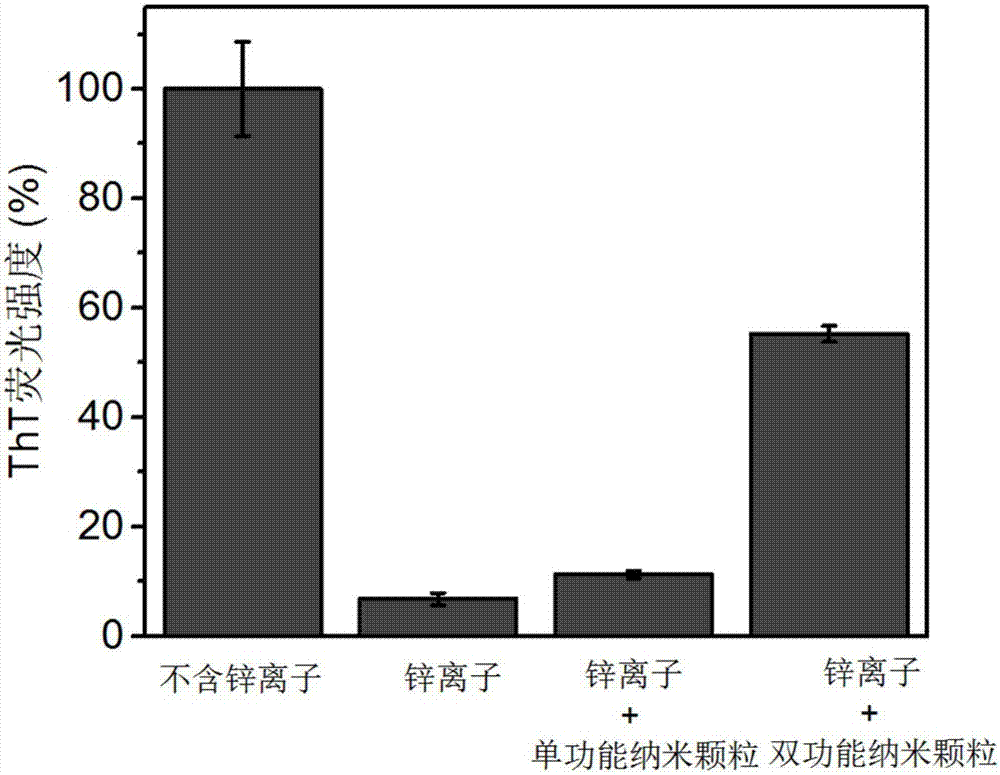

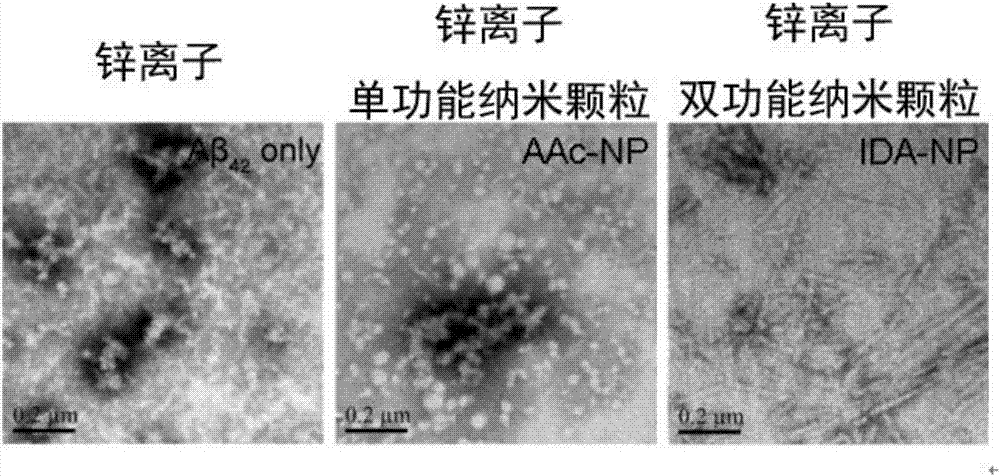

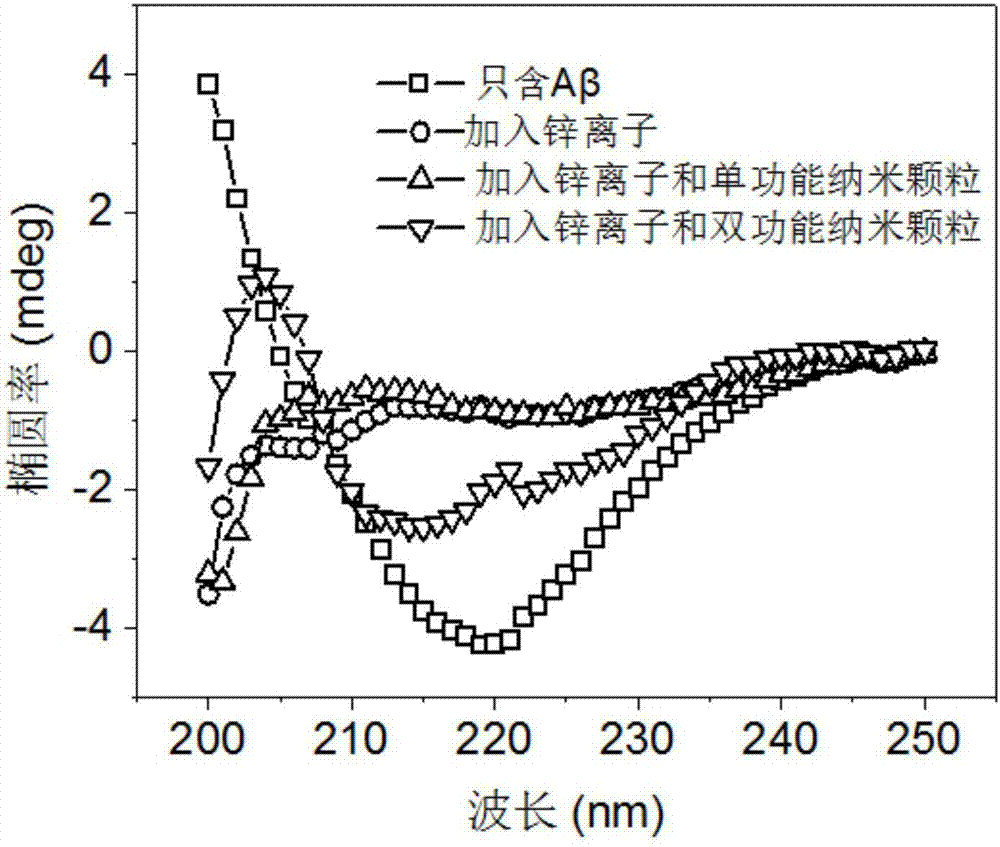

InactiveCN107254016AInhibits fibrotic aggregation processInhibits fibrosis aggregationOrganic active ingredientsNervous disorderDiseaseGlycidyl methacrylate

The invention relates to a preparation method of difunctional copolymerized nanoparticle inhibitor and application thereof in inhibition and detoxification of amyloid beta protein aggregation. The preparation method includes: using a connection product GMA-IDA of iminodiacetic acid (IDA) and glycidyl methacrylate (GMA) as a monomer; subjecting the monomer to free radical copolymerization reaction with monomers like N-isopropylaccrylamide (NIPAm) and n-tertbutyl acrylamide (TBAm) to synthesize the difunctional nanoparticle inhibitor having metal chelation ability and protein aggregation inhibiting ability. Average particle diameter of difunctional copolymerized nanoparticles synthesized by the method is 80-120nm. Metal ion chelation capacity of the nanoparticles synthesized by the method is higher than 700umol / g, and the nanoparticles can chelate metal ions in environment and inhibit fibrosis aggregation of Abeta42 and are a potential new drug raw material for treating Alzheimer's disease.

Owner:TIANJIN UNIV

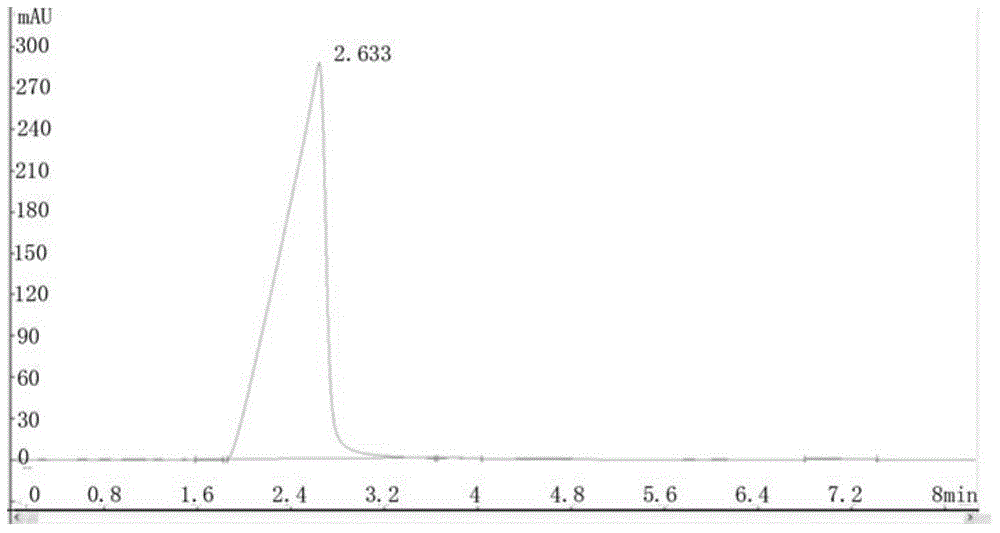

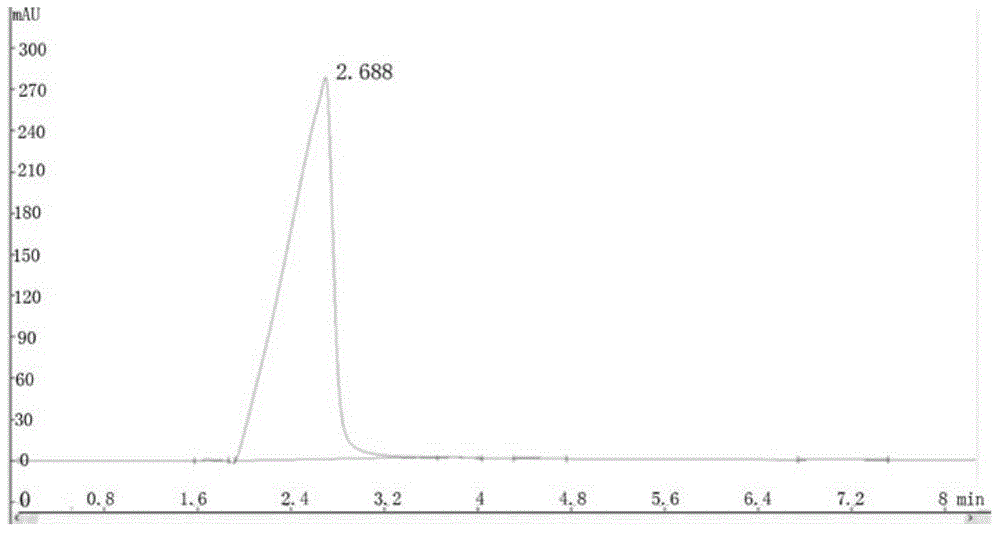

Synthesis method of tert-butyl acrylamide sulfonate

The invention discloses a synthesis method of tert-butyl acrylamide sulfonate, which comprises the following steps of: providing a first solution and a second solution, wherein the first solution is obtained through contact between acrylonitrile and a first sulfonating agent at -30 to 15 DEG C, and the second solution is obtained through contact between acrylonitrile and a second sulfonating agent at -30 to 15 DEG C; at -20 to 50 DEG C, enabling the first solution to contact with isobutene accounting for 10-100% of isobutene feed and the second solution to obtain a third solution; at -20 to 50 DEG C, enabling the third solution to contact with isobutene accounting for 0-90% of the isobutene feed to obtain a paste product; and separating and purifying the paste product to obtain tert-butyl acrylamide sulfonate. Through the method disclosed by the invention, other substances are not required in a reaction system, the production cost is greatly reduced, and the purity is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

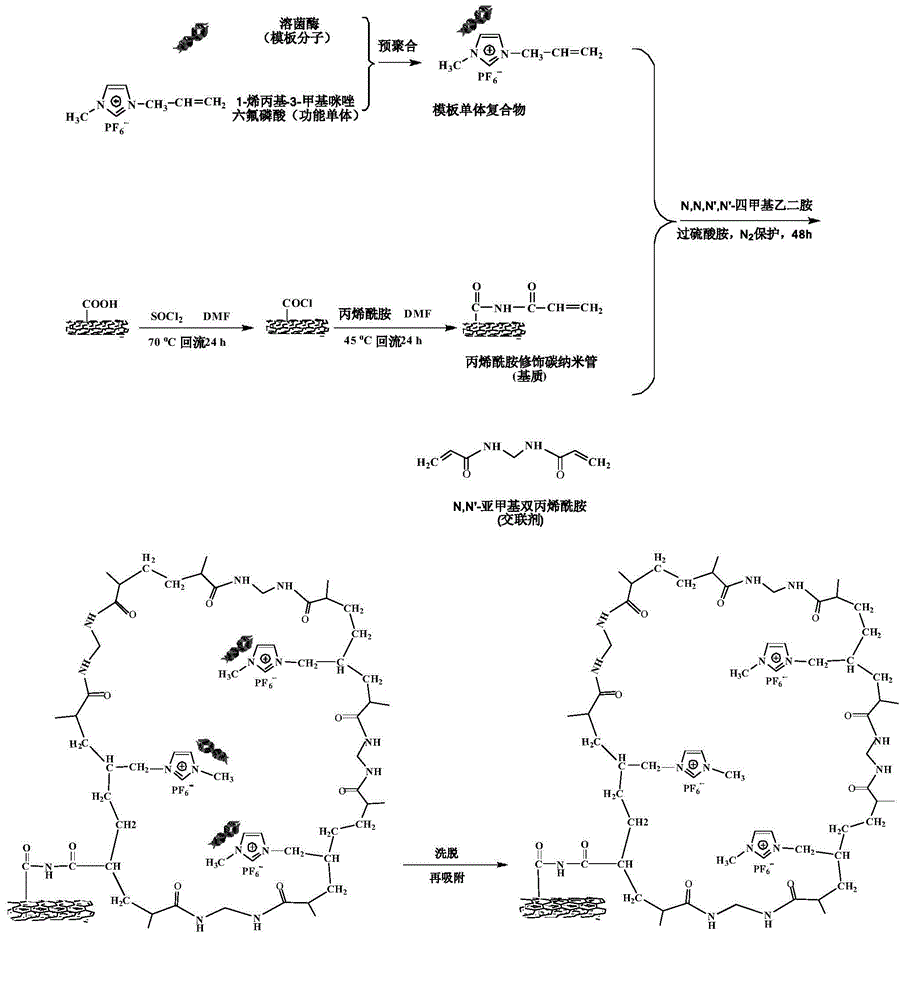

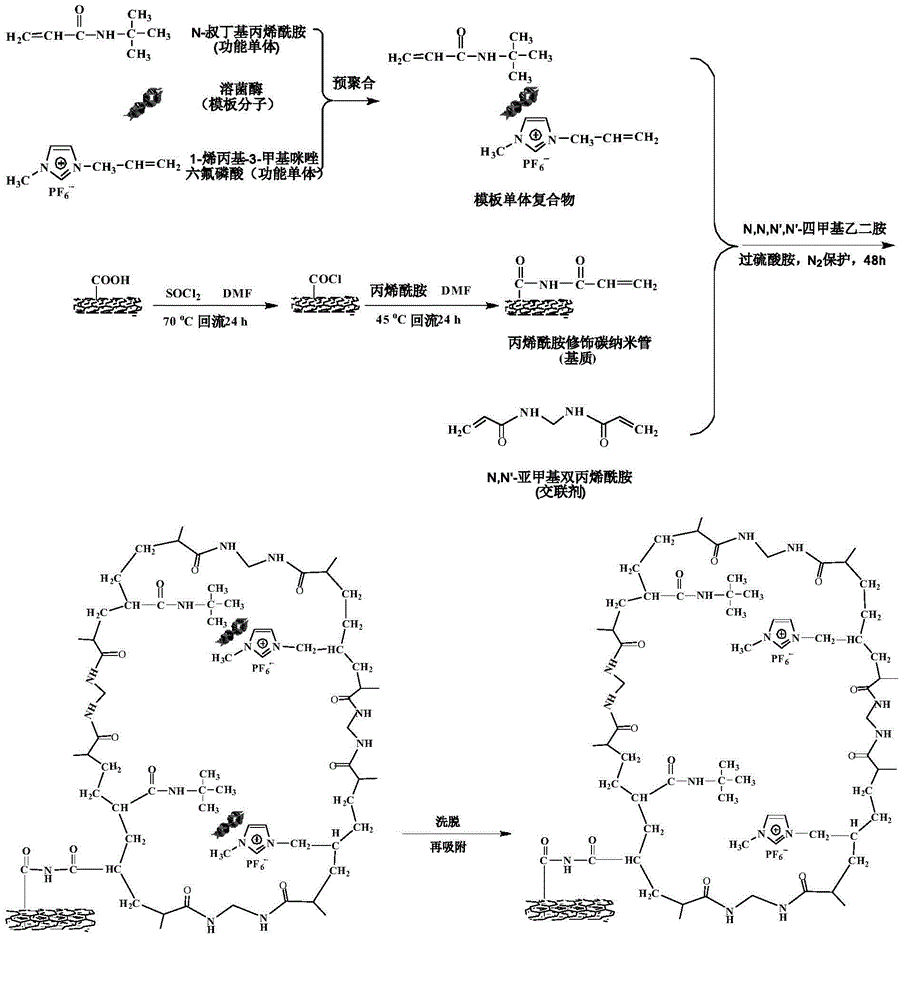

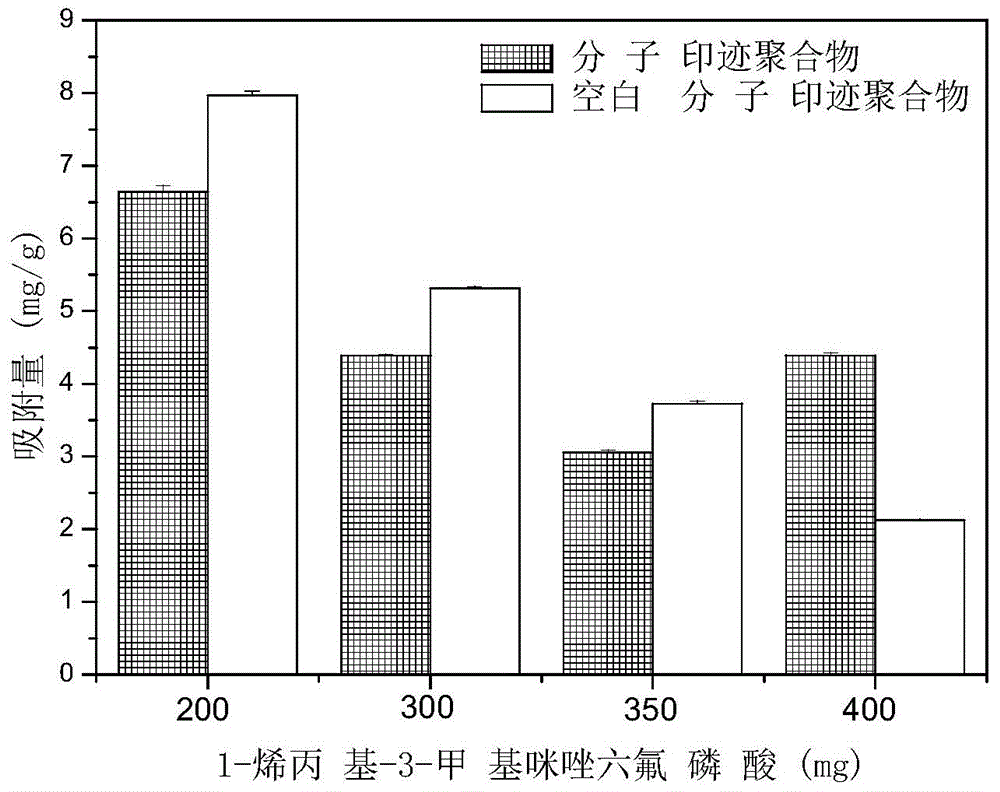

Carbon nano tube surface lysozyme molecularly-imprinted polymer and preparation method thereof

InactiveCN104945579AGood blotImprove adsorption capacityPigment treatment with non-polymer organic compoundsPolymer scienceFunctional monomer

The invention discloses a carbon nano tube surface lysozyme molecularly-imprinted polymer. The carbon nano tube surface lysozyme molecularly-imprinted polymer adopts lysozyme as a template molecule, adopts 1-allyl-3-methylimidazolium hexafluorophate ionic liquid and N-tert-butyl acrylamide as a mixing functional monomer, adopts an acrylamide modified carbon nanotube as a matrix, adopts a Tris-HCl buffer solution with the pH being 9 as a reaction system, is obtained under the effect of a cross-linking agent, an initiating agent and a catalyst and has the selective recognition capacity for lysozyme. The number of acting sites is multiple when the template molecule and the functional monomer are combined, the acting force is higher, more effective recognition sites can be formed in the preparation process of the molecularly-imprinted polymer, and therefore the printing effect and the preferential adsorption capacity for lysozyme are better.

Owner:HUAZHONG AGRI UNIV

Method for comprehensive utilization of 2-acrylamide-2-methylpropanesulfonic acid production process waste residue

InactiveCN105481714AReduce decompositionLow efficiencyOrganic compound preparationCarboxylic acid amide separation/purificationSolvent evaporationSolvent

The present invention relates to a method for comprehensive utilization of 2-acrylamide-2-methylpropanesulfonic acid production process waste residue. The method comprises: mixing AMPS production waste residue and a solvent, filtering, carrying out vacuum heating on the filtrate, continuously heating the remaining solid after evaporating the solvent so as to sublime the remaining solid, recovering the sublimed product to obtain N-t-butyl acrylamide, and obtaining 2-acrylamide-2-methylpropanesulfonic acid from the unsublimated remaining solid, wherein the purity of the recovered N-t-butyl acrylamide is more than or equal to 98%, and the purity of the 2-acrylamide-2-methylpropanesulfonic acid is more than or equal to 96%. The invention further provides a recovery apparatus for the method, wherein the recovery apparatus comprises a heatable separation container for heating the 2-acrylamide-2-methylpropanesulfonic acid production waste residue, a temperature-adjustable collection container for collecting the sublimed N-t-butyl acrylamide, and a vacuum system.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of production method of tert-butylacrylamide sulfonic acid

The invention relates to a production method of tert-butylacrylamide sulfonic acid, comprising: 1) forming an acrylonitrile solution containing a sulfonating agent; 2) passing the solution continuously into the horizontal stirring reactor to contact with isobutylene, forming a slurry product; 3) filtering the slurry product to obtain a filter cake and filtrate containing tert-butylacrylamide sulfonic acid; 4) drying the filter cake obtained in step 3) to obtain crude tert-butylacrylamide sulfonic acid product; 5) recrystallize and purify the crude product of tert-butylacrylamide sulfonic acid obtained in step 4) using aqueous acetic acid to obtain tert-butylacrylamide sulfonic acid and remaining waste liquid with a mass content of more than 99.3%; 6) The filtrate in step 3) and / or the remaining waste liquid in step 4 are evaporated to obtain a waste residue, and the waste residue is mixed and contacted with a treatment solvent, and then solid-liquid separation is performed to obtain tert-butylacrylamidesulfonic acid and tert-butylacrylamide.

Owner:CHINA PETROLEUM & CHEM CORP +1

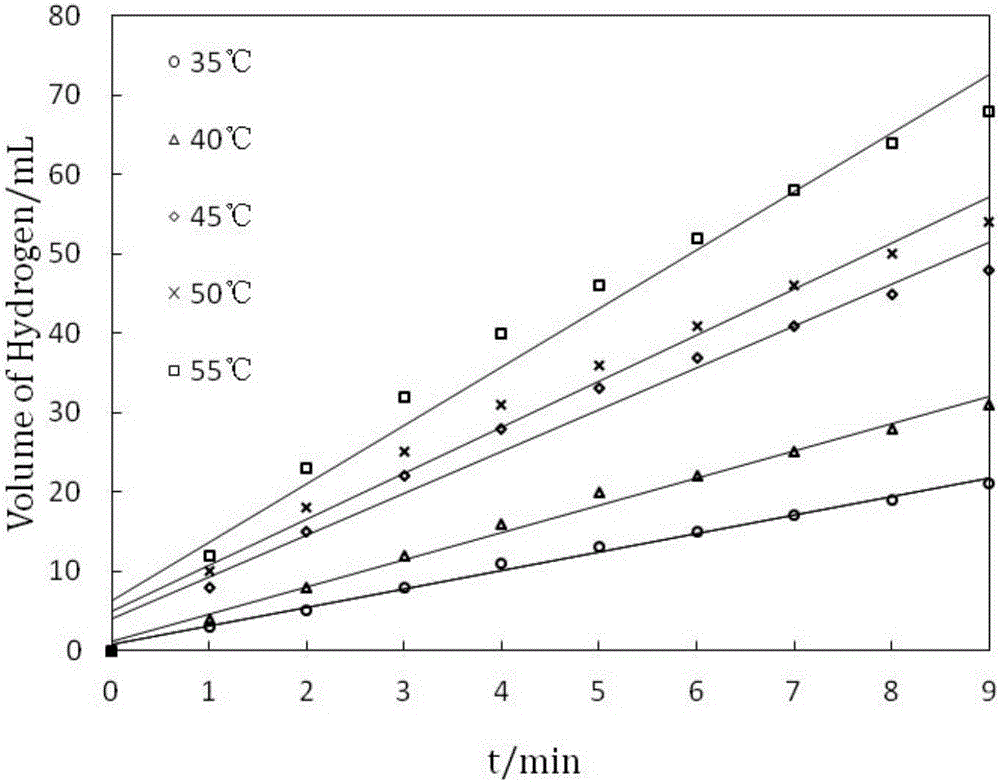

Preparation method of high-efficient copolymer silicon scale inhibitor

InactiveCN108640299ALarge specific surface areaHigh in situ deoxygenation capacityScale removal and water softeningIndustrial waterAqueous solution

The invention discloses a preparation method of a high-efficient copolymer silicon scale inhibitor, and the high-efficient copolymer silicon scale inhibitor is a terpolymer scale inhibitor prepared from 10 to 90 parts by weight of N-t-butyl acrylamide, 5 to 45 parts by weight of acrylic acid and 5 to 45 parts by weight of 2-acrylamide-2-methyl propane sulfonic acid as raw materials by a free radical aqueous solution polymerization method. The high-efficient copolymer silicon scale inhibitor has good scale inhibition performances, and can effectively prevent scaling problems of inorganic saltssuch as silicates on the surface of equipment during petroleum exploitation and industrial water circulation.

Owner:宁波金特信钢铁科技有限公司

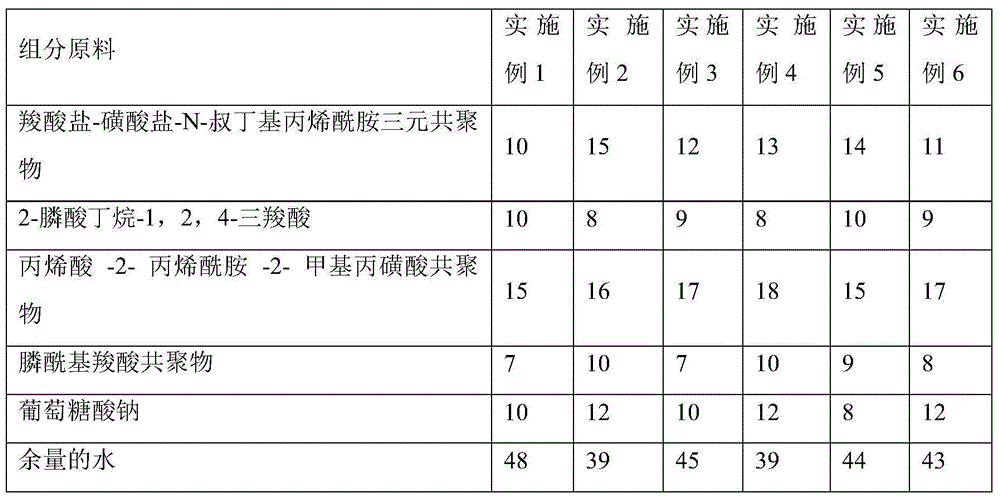

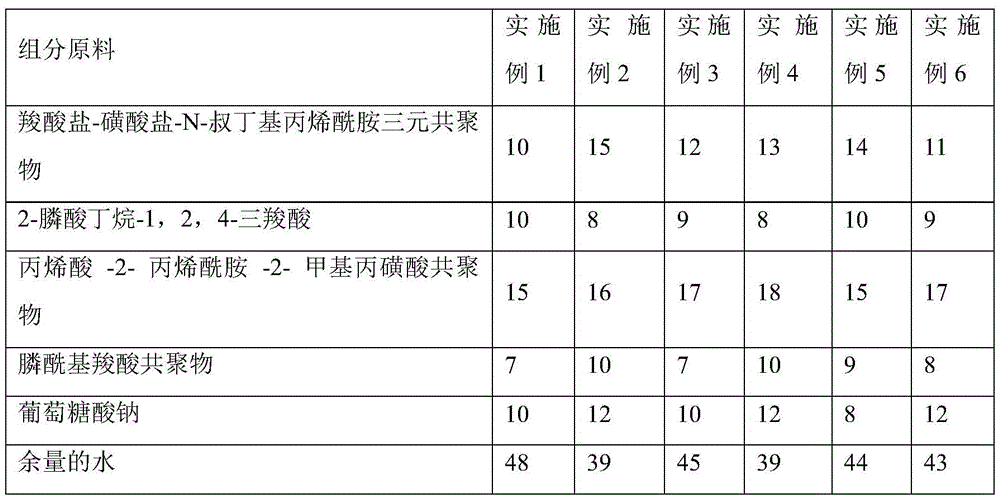

Low-phosphorus high-efficiency scale inhibition and dispersion agent

ActiveCN104528967AGood anti-scaling effectScale removal and water softeningTricarboxylic acidCarboxylic acid

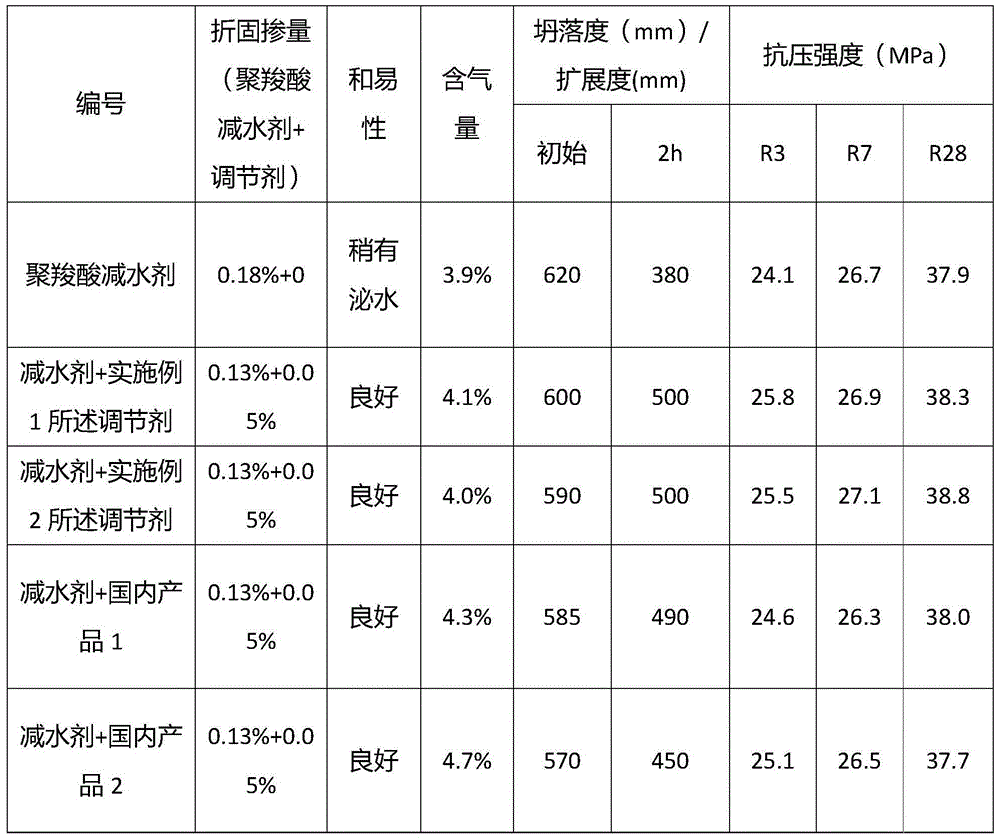

The invention relates to a water treatment agent and in particular relates to a low-phosphorus high-efficiency scale inhibition and dispersion agent. The scale inhibitor consists of the following components in percentage by weight: 10-15 percent of a carboxylate-sulfonate-N-tert-butyl acrylamide terpolymer, 8-10 percent of 2-phosphono butane-1,2,4-tricarboxylic acid PBTCA, 15-18 percent of an acrylic acid-2-acrylamide-2-methyl propane sulfonic acid copolymer, 7-10 percent of a phosphono carboxylic acid copolymer, 8-12 percent of sodium gluconate and the balance of water, wherein the raw materials of the components are commercially available industrial products. The low-phosphorus high-efficiency scale inhibition and dispersion agent disclosed by the invention is mainly used for treatment of industrial circulating water.

Owner:XINJIANG DELAND

Tert-butyl acrylamide sulfonic acid production method

The present invention relates to a tert-butyl acrylamide sulfonic acid production method, which comprises: 1) forming an acrylonitrile solution containing a sulfonating agent; 2) continuously introducing the solution into a horizontal stirring reactor to contact isobutene so as to form a slurry product; 3) filtering the slurry product to obtain the filter cake containing tert-butyl acrylamide sulfonic acid and the filtrate; 4) drying the filter cake obtained in the step 3) to obtain a tert-butyl acrylamide sulfonic acid crude product; 5) adopting an acetic acid aqueous solution to carry out recrystallization purification on the tert-butyl acrylamide sulfonic acid crude product obtained in the step 4) to obtain the tert-butyl acrylamide sulfonic acid with the mass content of more than 99.3% and the remaining waste liquid; and 6) evaporating the filtrate in the step 3) and / or the remaining waste liquid in the step 4) to obtain the waste residue, carrying out mixing contact on the waste residue and a treatment solvent, and carrying out solid-liquid separation to obtain the tert-butyl acrylamide sulfonic acid and the tert-butyl acrylamide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of acrylamido tertiary butyl sulfonic acid

ActiveCN104250219ARealize continuous productionHigh yieldSulfonic acid preparationAcrylonitrileSlurry

The invention relates to a production method of acrylamido tertiary butyl sulfonic acid. The production method comprises the following steps of 1, mixing acrylonitrile and a sulfonating agent to obtain a sulfonating agent-containing acrylonitrile solution, 2, providing a horizontal stirring reactor, and continuously feeding the mixed solution obtained by the step into the horizontal stirring reactor so that the mixed solution contacts with isobutene and product slurry is formed, 3, continuously discharging the product slurry from the horizontal stirring reactor, and filtering the product slurry to obtain acrylamido tertiary butyl sulfonic acid-containing filter cake, and 4, drying the filter cake obtained by the step 3 to obtain an acrylamido tertiary butyl sulfonic acid crude product having mass content more than 96.0%.

Owner:CHINA PETROLEUM & CHEM CORP +1

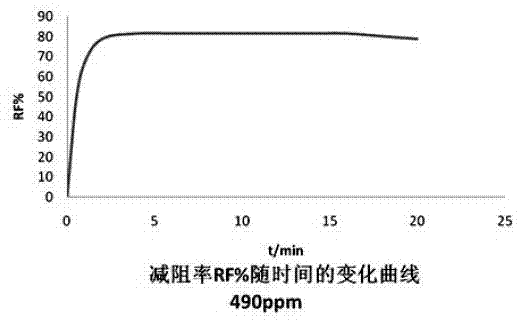

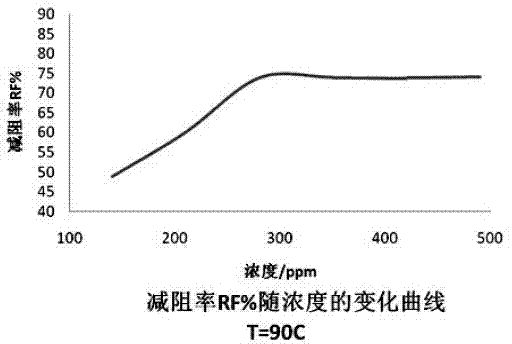

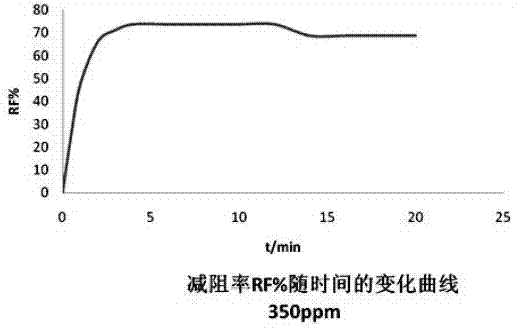

Preparation technology of water phase transmission drag reducer for slickwater fracturing

ActiveCN103539893AExcellent drag reduction rateIncrease productivityOrganic compound preparationCarboxylic acid amide separation/purificationWater qualityHydrolysis

The invention discloses a preparation technology of a water phase transmission drag reducer for slickwater fracturing, and belongs to the field of oil field chemical water phase drag reduction technology. The preparation technology comprises following steps: an acrylamide monomer aqueous solution with a mass concentration of 18.5 to 25.5% is prepared; tert-butylacrylamide is added, wherein the content of tert-Butylacrylamide is 0.2 to 2.0wt% of that of the acrylamide monomer aqueous solution; sodium carbonate is added, wherein the content of sodium carbonate is 2.5 to 8.0wt% of that of the acrylamide monomer aqueous solution; a chelating agent, a chain transfer agent, a chain extender and a water soluble azo-compound are added; the mixture is subjected to polymerization and hydrolysis so as to obtain gel blocks; the gel blocks are processed so as to obtain polyacrylamide powder; and the polyacrylamide powder is mixed with sodium chloride particles so as to obtain the water phase transmission drag reducer. An optimized application concentration of the water phase transmission drag reducer ranges from 250 to 500ppm; compatibility with common bactericides, antiswelling agents and discharge aiding agents is excellent; solution formed by the water phase transmission drag reducer is stable; drag reduction efficiency is high and lasts long; influence of water mineralization degree on preparation of slickwater is less; and the water phase transmission drag reducer is suitable for water with more than 10% calcium chloride.

Owner:上海三浦生物科技有限公司

Synthesis process of sulfonic group containing dirt dispersion agent

The invention provides a synthesis process of a sulfonic group containing dirt dispersion agent. The synthesis process comprises the following steps: (1) adding sodium hypophosphite into a kettle residual mixed solution in the process for producing 2-acrylamido-2-methyl propane sulfonic acid, wherein the weight ratio of the mixed solution to the sodium hypophosphite is 90 to (1-2); (2) heating the mixed solution in the step (1), and stopping the heating when the temperature rises to 80 to 85 DEG C; (3) dropwise adding crylic acid and initiator into the mixed solution of the step (2), wherein the weight ratio of the cryic acid to the initiator is 20 to (1-2); (4) maintaining the temperature for 1 to 1.5 hours, and cooling the mixed solution to 45 to 55 DEG C; (5) adding sodium hydroxide of concentration of 50% into the mixed solution of the step (4), adjusting the pH to 3 to 4, and obtaining brownish red clear liquid. By adopting the synthesis process of the sulfonic group containing dirt dispersion agent, the problem for treating the kettle residue after acrylonitrile is distilled and recovered in the process for producing 2-acrylamido-2-methyl propane sulfonic acid or for co-producing N-tert-butyl acrylamide can be solved.

Owner:HEFEI ALL PLUS ENVIRONMENTAL TECH CO LTD

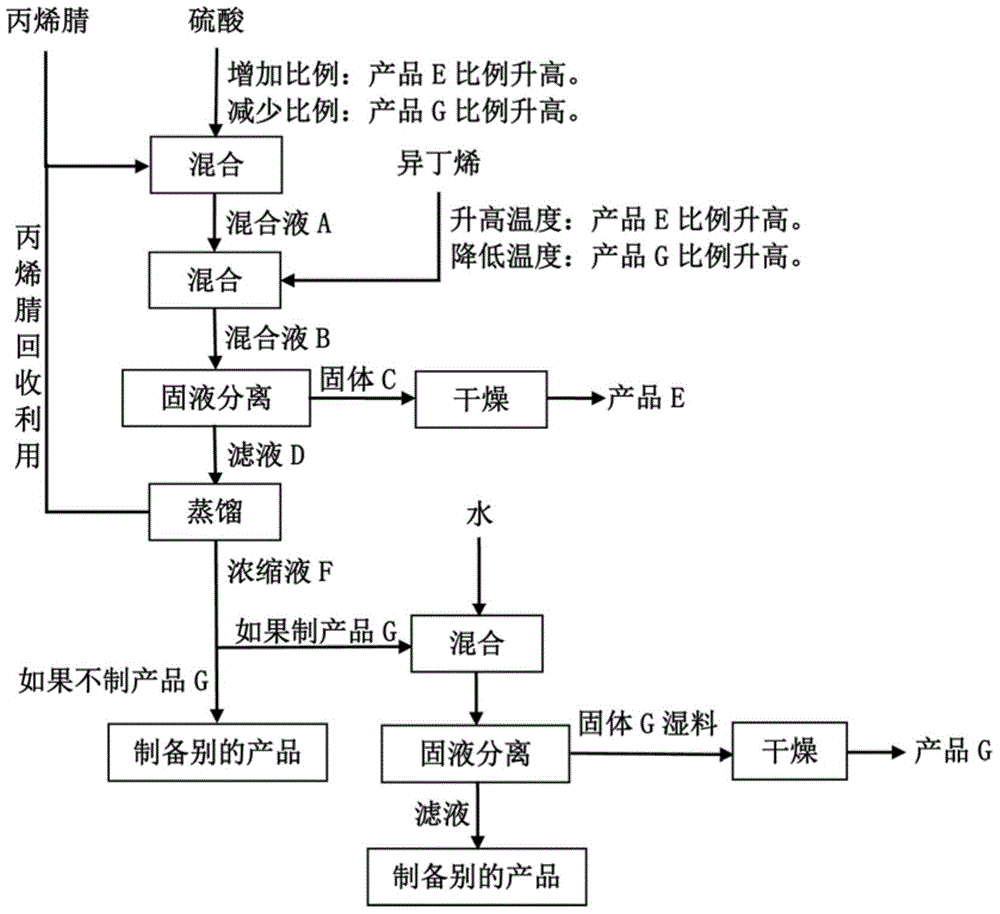

Combined production method

InactiveCN104926697AIncrease productionHigh purityOrganic compound preparationCarboxylic acid amides preparationFiltrationAcrylonitrile

The invention provides a combined production method which comprises the following steps: according to a weight ratio of acrylonitrile to concentrated sulfuric acid being 5:(1-2), sufficiently mixing acrylonitrile and concentrated sulfuric acid to obtain a mixture A; according to a weight ratio of the mixture A to isobutene being 13:(1-3), sufficiently mixing the mixture A and isobutene to obtain a mixture B, wherein a solid in the mixture B is precipitated; conducting solid-liquid separation on the mixture B to obtain a solid C and a filtration liquid D; drying the solid C to obtain a product E, namely 2-acrylamide-2-methylpropane sulfonic acid; distilling the filtration liquid D to obtain an acrylonitrile solution and a concentrated solution F through recovery; adding water of which the weight is the same as the concentrated solution F into the concentrated solution F to ensure that a solid is precipitated from the concentrated solution F, and then carrying out filtration to obtain a solid product G, namely N-tert-butyl acrylamide. The combined production method has the advantages that residues from the production of 2-acrylamide-2-methyl-1-propanesulfonic acid are utilized, so that resource conservation is realized, and the production cost is reduced.

Owner:HEFEI ALL PLUS ENVIRONMENTAL TECH CO LTD

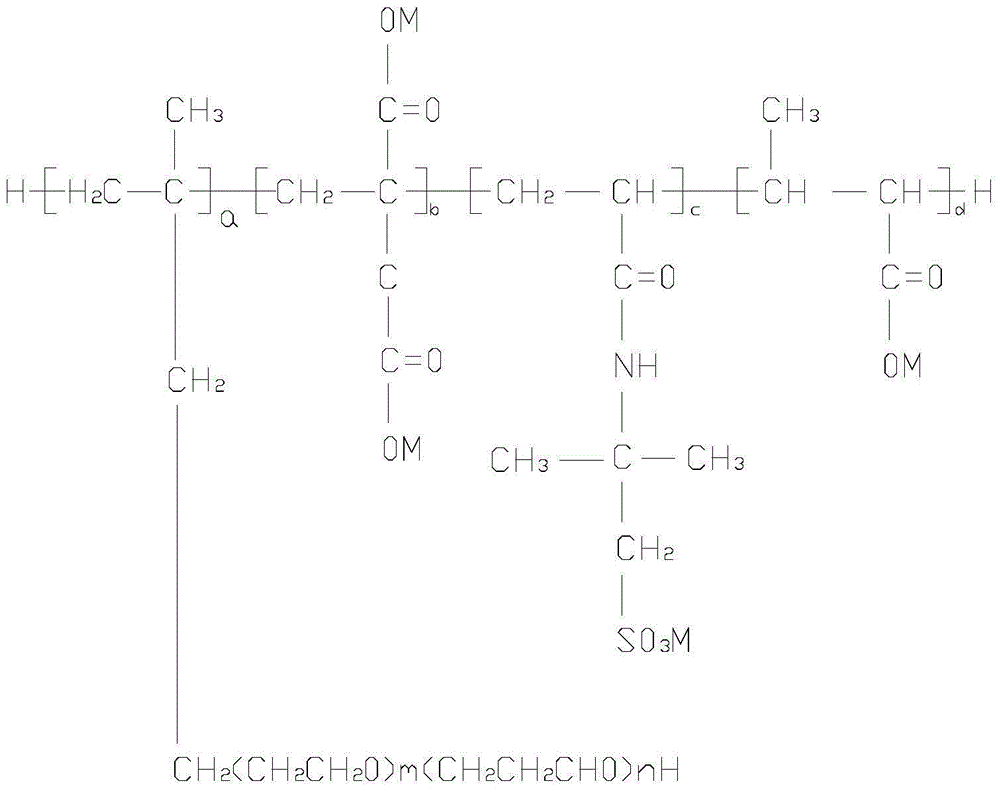

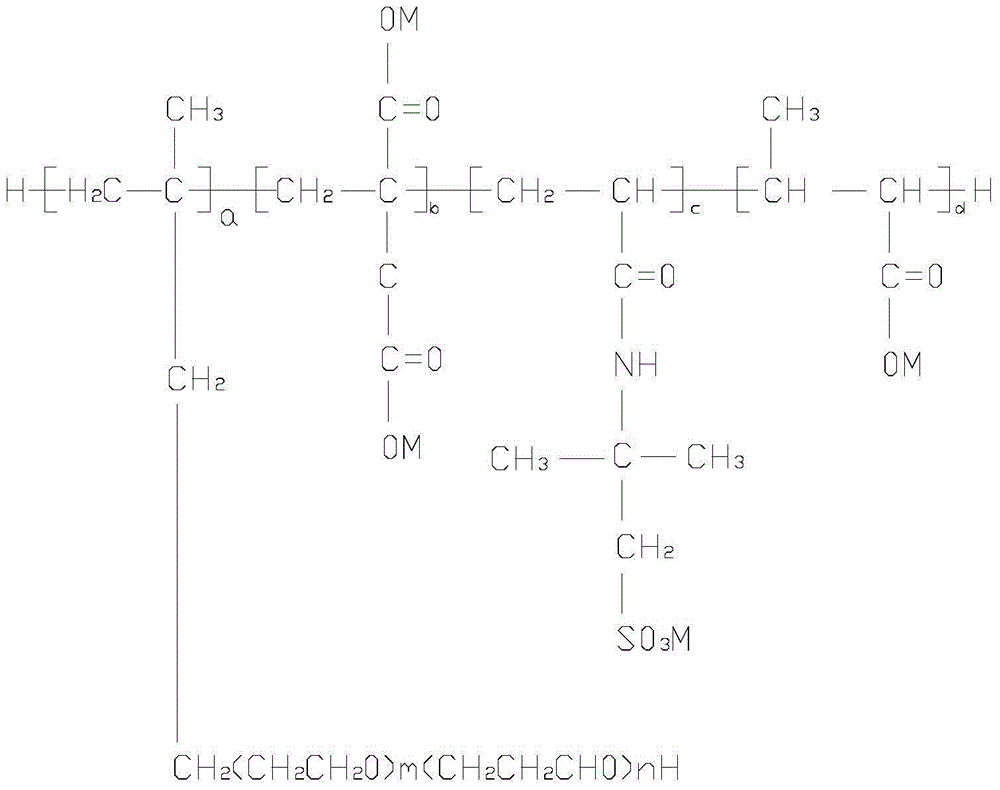

Modifier for polycarboxylate-type water reducer for concrete and preparation method of modifier

The invention relates to a modifier for a polycarboxylate-type water reducer for concrete and a preparation method of the modifier. The modifier is prepared by polymerizing polyethylene glycol isoamyl allyl ether, itaconic anhydride, t-butyl acrylamide sulfonic acid and crotonic acid unsaturated monomers in the presence of an initiator and a molecular weight modifier in a water solution. The modifier has the advantages that the doping amount is low, the cement adaptability is good, the holding capacity of slump constant of concrete is strong, the cost is low and synthesizing process is carried out at normal temperature. The preparation method of the modifier has the beneficial effects that the process is simple, the energy is saved in a synthetic production process, and the production cost is effectively lowered.

Owner:CHONGQING XINCAI CONCRETE GRP

Method and apparatus for recovering N-t-butyl acrylamide

InactiveCN105481713AHigh purityGood lookingCarboxylic acid amide separation/purificationSolvent evaporationSorbent

The present invention relates to a method for recovering N-t-butyl acrylamide. The method comprises: mixing waste residue obtained after 2-acrylamide-2-methylpropanesulfonic acid production, a solvent and an adsorbent, filtering, carrying out vacuum heating on the filtrate, continuously heating the remaining solid after evaporating the solvent so as to sublime the remaining solid, and recovering the sublimed product to obtain the N-t-butyl acrylamide, wherein the vacuum heating is performed at a temperature of 40-120 DEG C under a pressure of 1-50k Pa, and the purity of the recovered N-t-butyl acrylamide is more than or equal to 99.5%. The present invention further provides a recovery apparatus for the method, wherein the recovery apparatus comprises a heatable separation container for heating the waste residue obtained after the 2-acrylamide-2-methylpropanesulfonic acid production, a temperature-adjustable collection container for collecting the sublimed N-t-butyl acrylamide, and a vacuum system.

Owner:CHINA PETROLEUM & CHEM CORP +1

A low-phosphorus and high-efficiency scale-inhibiting dispersant

ActiveCN104528967BGood anti-scaling effectScale removal and water softeningTricarboxylic acidGluconic acid

The invention relates to a water treatment agent and in particular relates to a low-phosphorus high-efficiency scale inhibition and dispersion agent. The scale inhibitor consists of the following components in percentage by weight: 10-15 percent of a carboxylate-sulfonate-N-tert-butyl acrylamide terpolymer, 8-10 percent of 2-phosphono butane-1,2,4-tricarboxylic acid PBTCA, 15-18 percent of an acrylic acid-2-acrylamide-2-methyl propane sulfonic acid copolymer, 7-10 percent of a phosphono carboxylic acid copolymer, 8-12 percent of sodium gluconate and the balance of water, wherein the raw materials of the components are commercially available industrial products. The low-phosphorus high-efficiency scale inhibition and dispersion agent disclosed by the invention is mainly used for treatment of industrial circulating water.

Owner:XINJIANG DELAND

Thermally-induced physical cross-linked colored hydrogel and preparation method thereof

ActiveCN112812327AThe method is simpleSimple processAgainst vector-borne diseasesHydrophilic monomerPolymer science

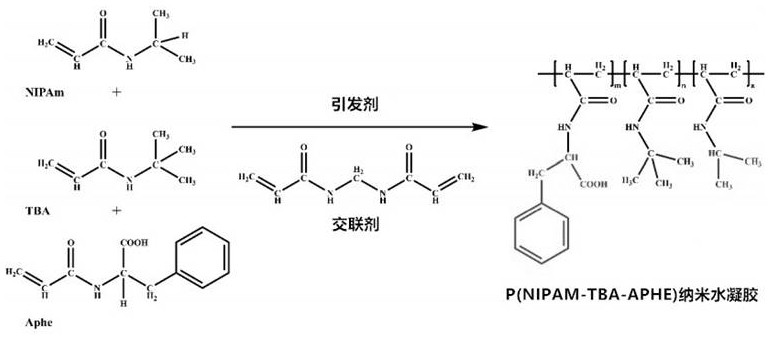

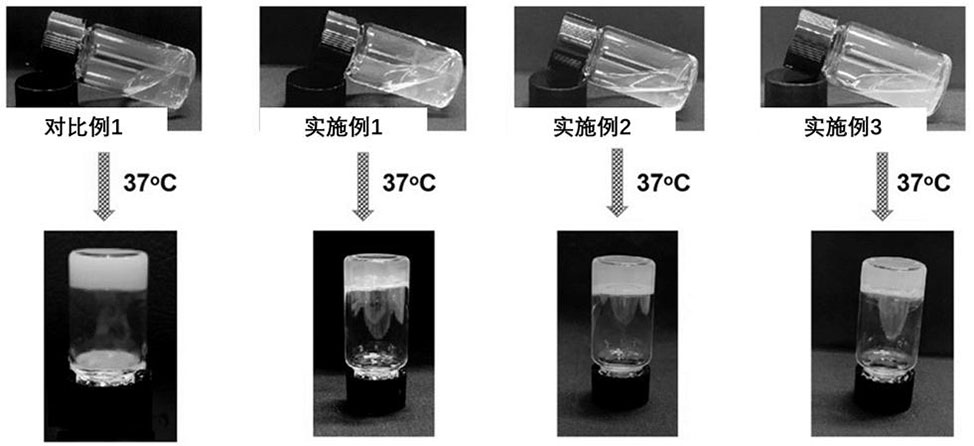

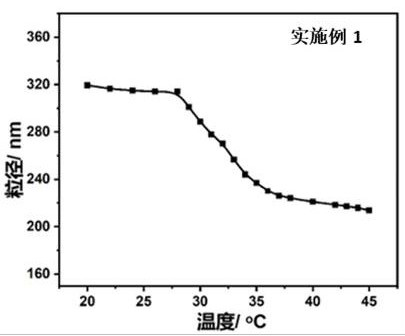

The invention particularly relates to thermally-induced physical cross-linked colored hydrogel and a preparation method thereof. The preparation method comprises the following steps: firstly, by taking N-isopropylacrylamide (NIPAm) as a functional monomer for providing temperature sensitivity for a polymer, taking N-tert-butyl acrylamide (TBA) as a hydrophobic monomer and taking L-N-propionyl phenylalanine (Aphe) as a hydrophilic monomer, carrying out copolymerization by controlling and adjusting the introduction amount of the Aphe, so as to obtain the P (NIPAm-TBA-Aphe) ternary copolymerized nano hydrogel with temperature responsiveness. Then, temperature is adopted to trigger in-situ implementation of a sol-gelation process and keep a bright structural color: the nano hydrogel is heated within a certain temperature range, the concentration range of the nano hydrogel is adjusted, the nano hydrogel is converted from a flowable solution state to a non-flowable macroscopic jelly-like hydrogel state, meanwhile, the hydrogel has the bright structural color, and in addition, the in-situ sol-gel conversion has reversibility.

Owner:ANHUI MICRODELIVERY SMART MICROCAPSULE SCI & TECH CO LTD

Method for extracting N-tert-butyl acrylamide

The invention provides a method for extracting N-tert-butyl acrylamide, which comprises the following steps: by using kettle residues for producing 2-acrylamide-2-methyl propanesulfonic acid as a rawmaterial, the kettle residues is mixed with water with stirring to obtian slurry; and the slurry is subjected to filter pressing, a filter cake obtained after filter pressing is an N-tert-butyl acrylamide crude product, and then N-tert-butyl acrylamide crude product treatment is carried out. The method is high in extraction yield, and the extracted N-tert-butyl acrylamide is high in purity and good in quality.

Owner:寿光市荣晟新材料有限公司

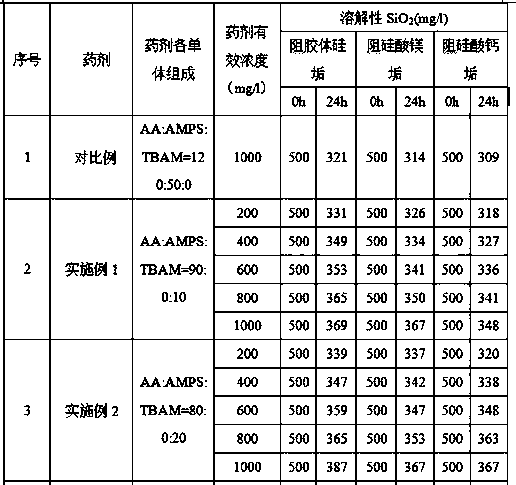

Silica scale inhibitor, preparation method and application

InactiveCN109438610AThe synthesis process is simpleEasy to operateScale removal and water softeningNon-contaminated water treatmentBiological bodyColloid

The invention discloses a silica scale inhibitor, and a preparation method and application thereof. The silica scale inhibitor is formed by performing copolymerization on crylic acid, 2-acrylamido-2-methylpropane sulfonic acid and N-tert-butyl acrylamide, simple in preparation technology and low in production cost, and has an excellent inhibition effect; moreover, the silica scale inhibitor has notoxic and / or side effect on organism, is safe to use, can meet the requirements on silica scale inhibition in the field of industrial circulating cooling water treatment, and is particularly applicable to inhibition of colloid silica scale or silicate scale in a circulating systems, with high silicon content, in raw water or circulating water.

Owner:SHANDONG UNIV +1

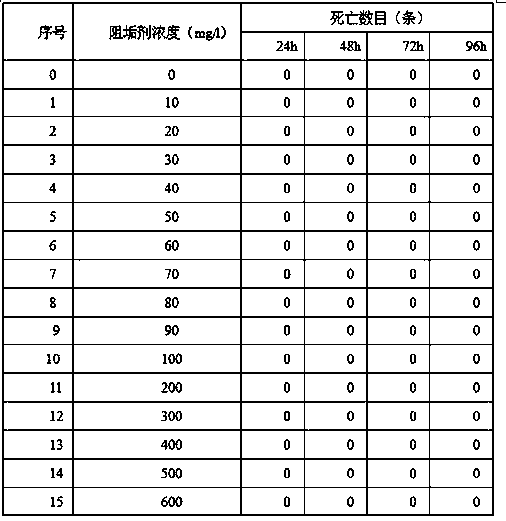

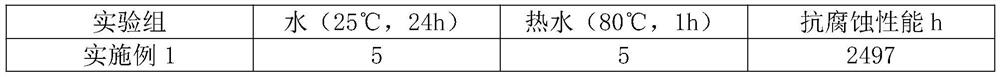

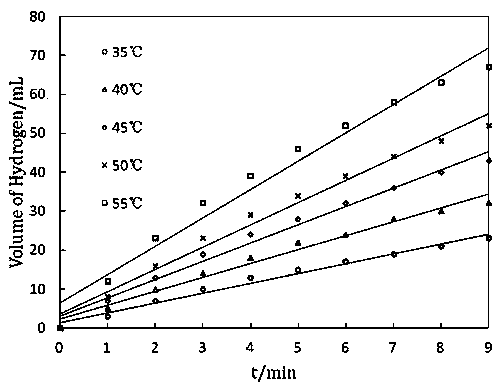

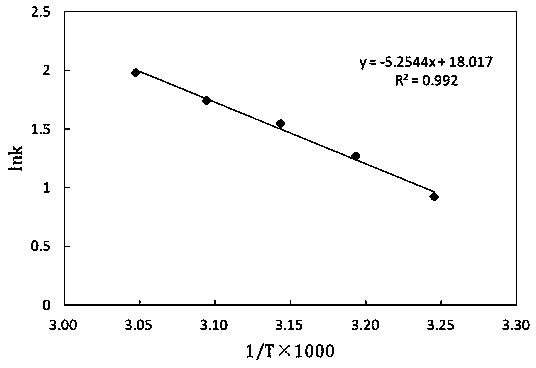

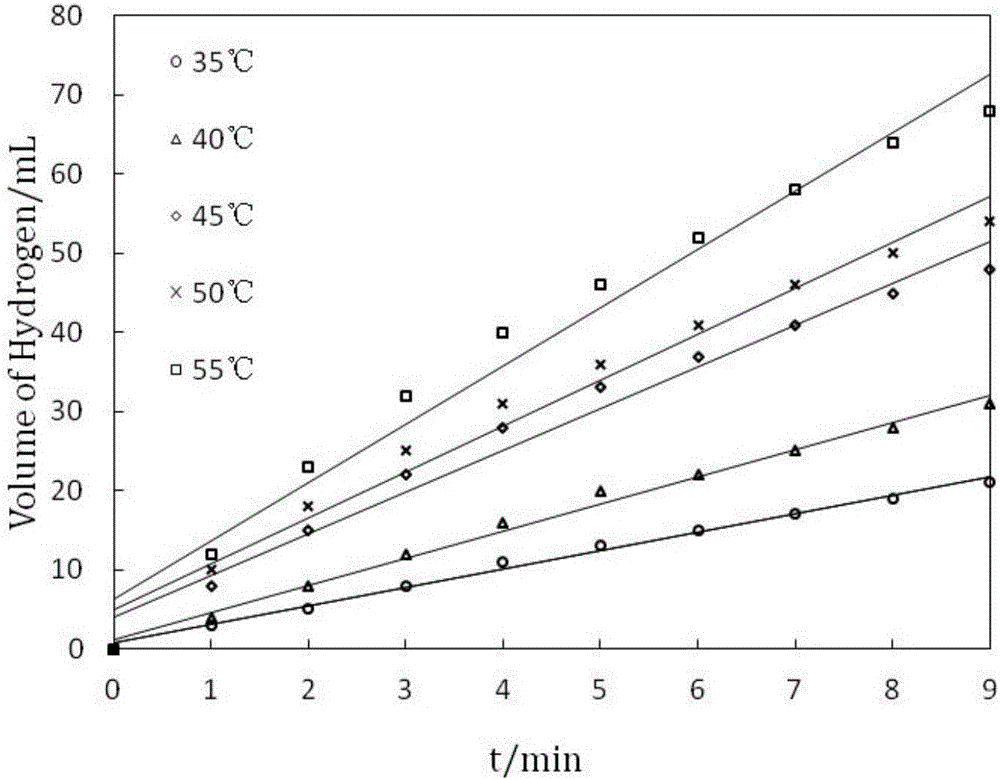

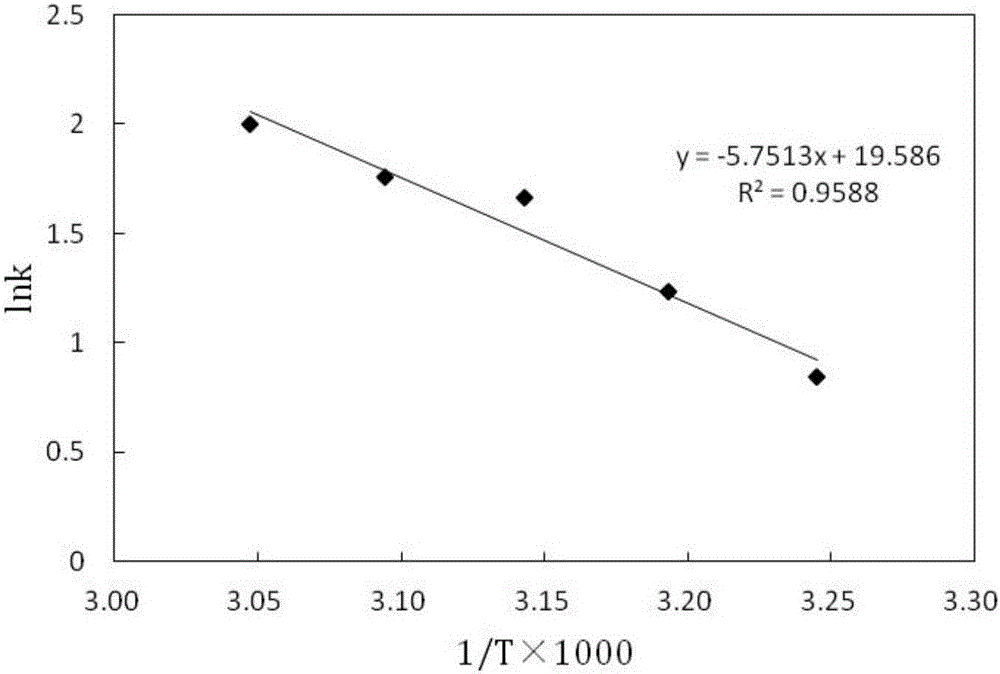

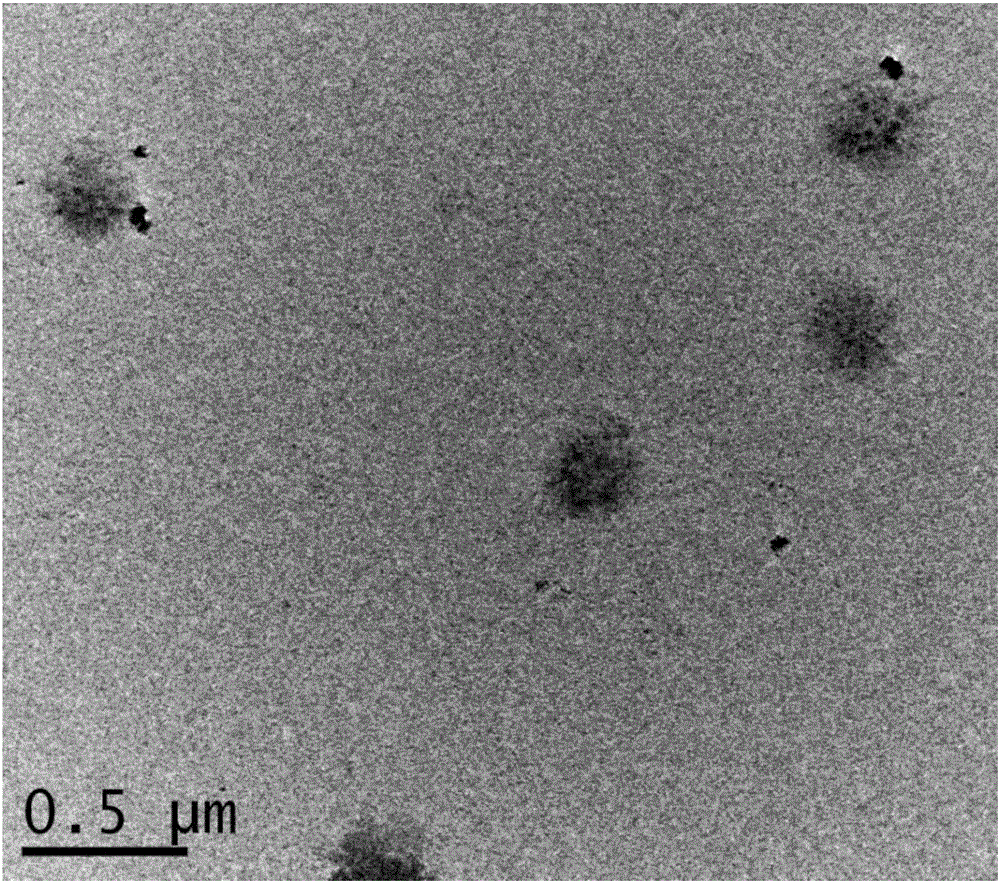

Terpolymer nanosphere loaded Ni-B catalyst

InactiveCN105817268AHigh reactivityHigh hydrogen yieldOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsCross-linkSynthesis methods

The invention provides a terpolymer nanosphere loaded Ni-B catalyst. The catalyst adopts N-isopropyl acrylamide, 2-acrylamide-2-methyl propanesulfonic acid and n-tert-butyl acrylamide as copolymerized monomers, adopts N,N'-methylene bisacrylamide as a cross-linking agent, and adopts potassium peroxodisulfate as an initiator, and terpolymer nanospheres are synthesized through a soap-free emulsion polymerization method; the nanospheres are dispersed into a nickel sulfate solution for absorbing nickel ions, and adsorbed nickel ions are reduced into nickel metal after centrifuging is performed; the terpolymer nanospheres containing a small amount of nickel metal are dispersed into a nickel plating solution for chemical nickel plating, and the terpolymer nanosphere loaded Ni-B catalyst is obtained. According to the catalyst, raw materials are easy to obtain, the synthesis method is simple, the catalysis efficiency is high, the reaction operation is simple, repeated usage can be achieved, and the terpolymer nanosphere loaded Ni-B catalyst is suitable for catalyzing a sodium borohydride hydrolysis hydrogen production reaction.

Owner:SHAOXING UNIVERSITY

Epoxy floor coating with formaldehyde absorption performance and preparation method thereof

The invention discloses an epoxy floor coating with formaldehyde absorption performance and a preparation method thereof. The epoxy floor coating is composed of a component A and a component B, wherein the component A and the component B are mixed according to a mass ratio of 1: (1-2). The component A comprises the following raw materials: 15-20 parts by weight of china clay, 3-5 parts by weight of an adhesive, 1-3 parts by weight of a dispersant, 0.5-1 part by weight of a water-resistant agent, 3-4 parts by weight of anhydrous sodium sulfate, 5-9 parts by weight of N-tert-butyl acrylamide, 2-5 parts by weight of 2-naphthol and 1-3 parts by weight of a rheological modifier. The component B comprises the following components in parts by weight: 10-15 parts of epoxy resin, 2-4 parts of a stabilizer, 6-8 parts of titanium dioxide, 1-3 parts of a rheological modifier, 2-4 parts of methallyl chloride, 5-7 parts of sodium m-aminobenzene sulfonate, 5-7 parts of 2-aminophenol-4-sulfonylaniline and 1-3 parts of a defoaming agent. According to the invention, low-toxicity and pollution-free titanium dioxide is added, so the decomposition efficiency of the product on organic pollutants such as formaldehyde is improved, and the effect that use efficiency is reduced due to the fact that the coating is caked can also be prevented.

Owner:江苏德莱利建筑装饰工程有限公司

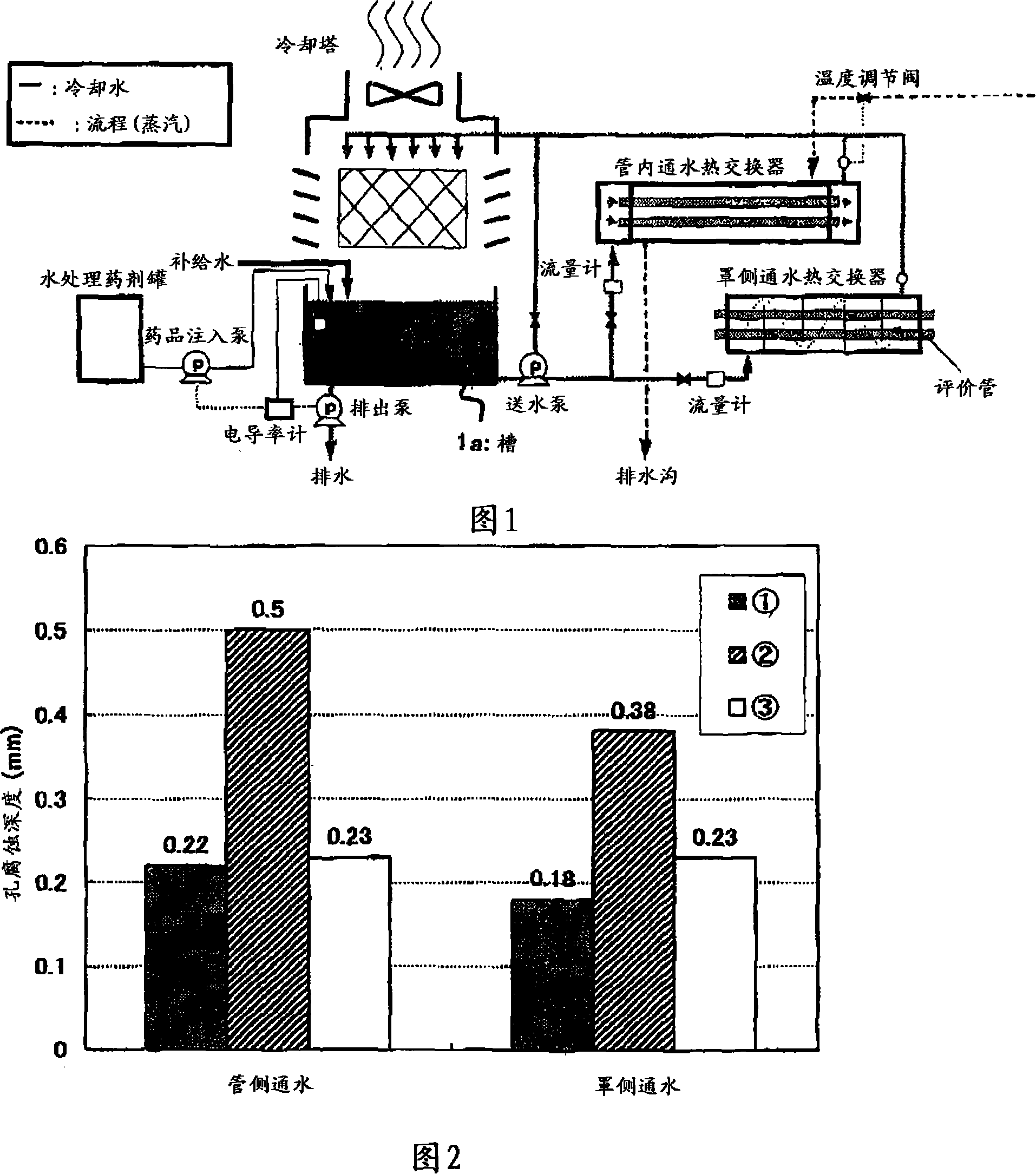

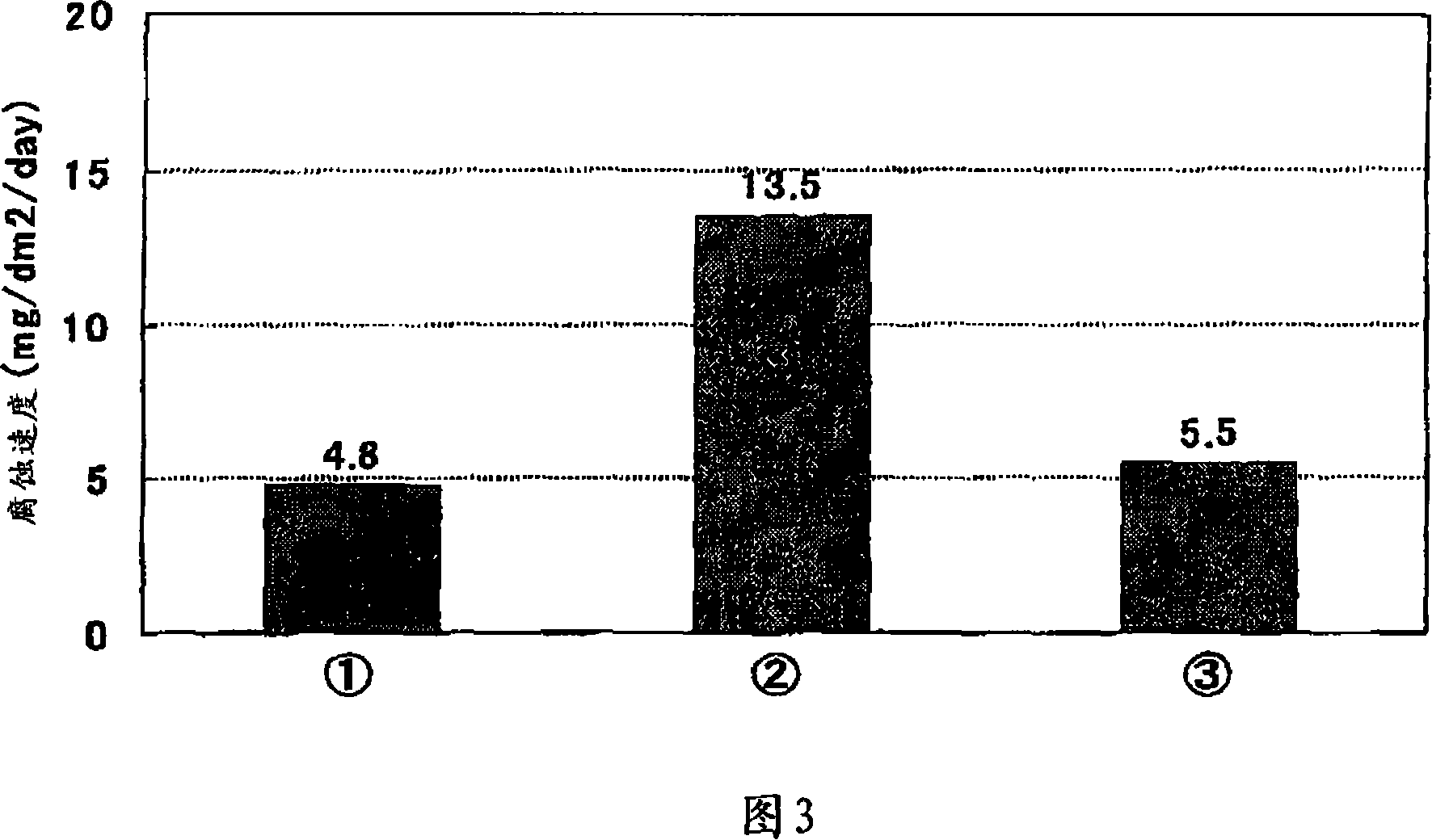

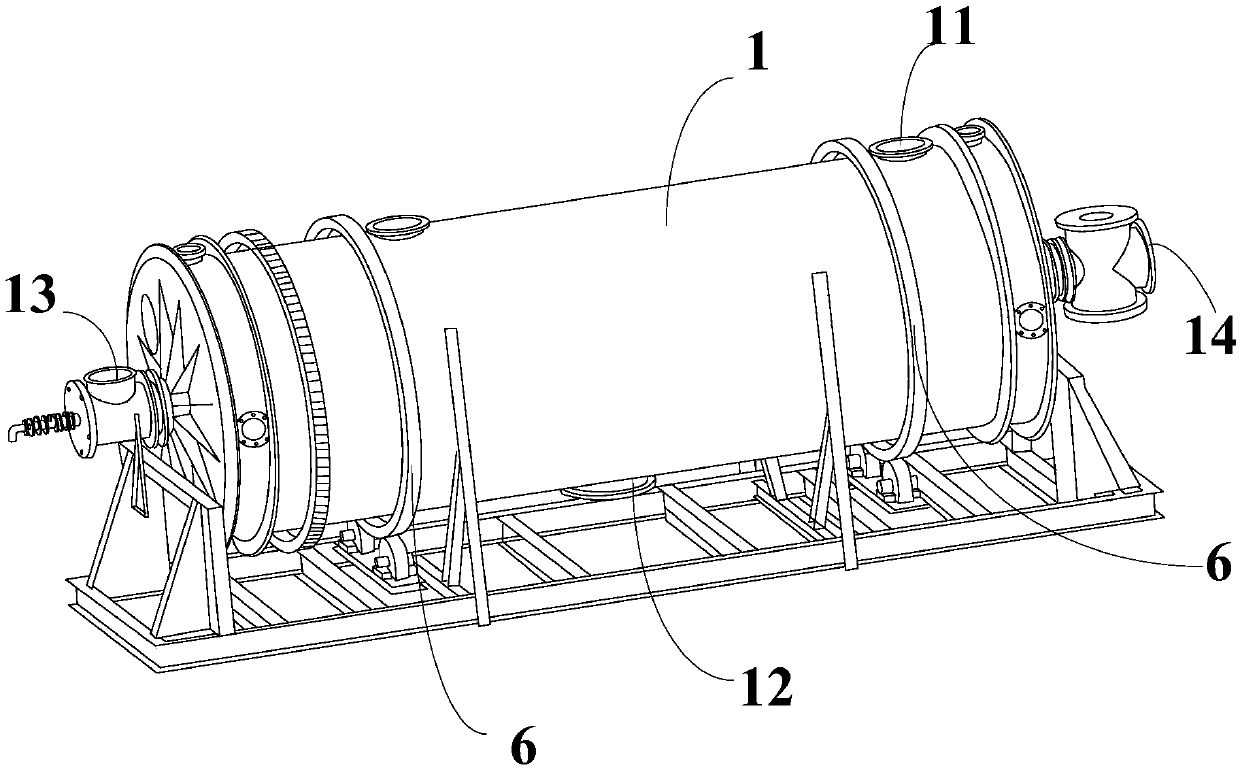

Anticorrosive agent and anticorrosive method

The present invention provides an anticorrosive agent which has excellent corrosion prevention especially pit corrosion prevention effect in the non-phosphor and non-metal system, and a corrosion inhibition method by using the anticorrosive agent. The anticorrosive agent includes silicic acid or the salt of the silicic acid and the sulphonic acid system polymer, and includes alkali under the condition of liquefaction. The sulphonic acid system polymer can be at least one of the propenoic acid and 2-acrylamide-2-cymene propanesulfonic acid system copolymer, propenoic acid and isoprene sulphonic acid and 3-allyloxy-2-hydroxy-group propanesulfonic acid system terpolymer, propenoic acid and 2-acrylamide -2-cymene propanesulfonic acid and tert-butyl group acrylamide system terpolymer. In addition, the present invention prevents the corrosion especially the pit corrosion of the object water system by adding effective amount of the anticorrosive agent.

Owner:KURITA WATER INDUSTRIES LTD

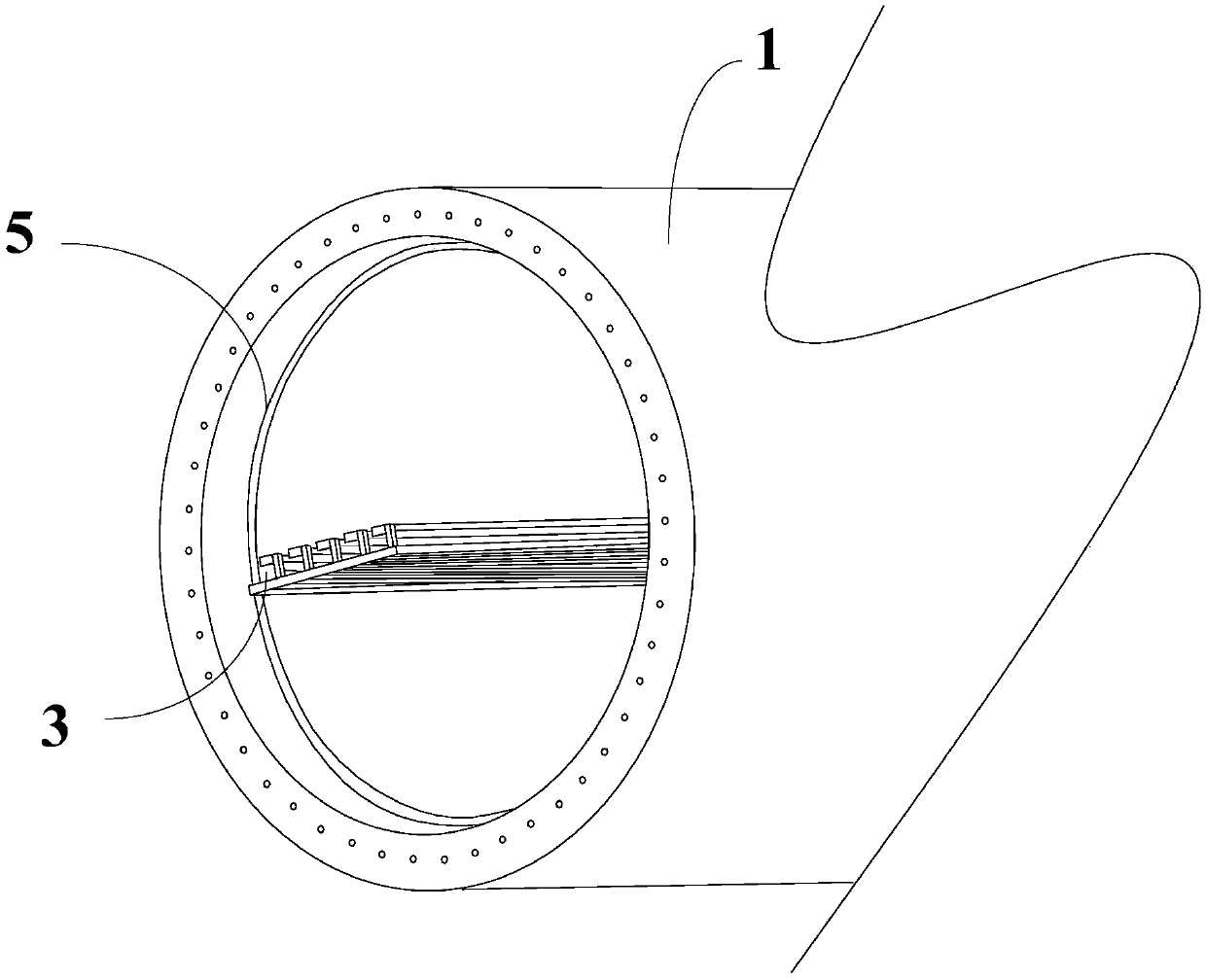

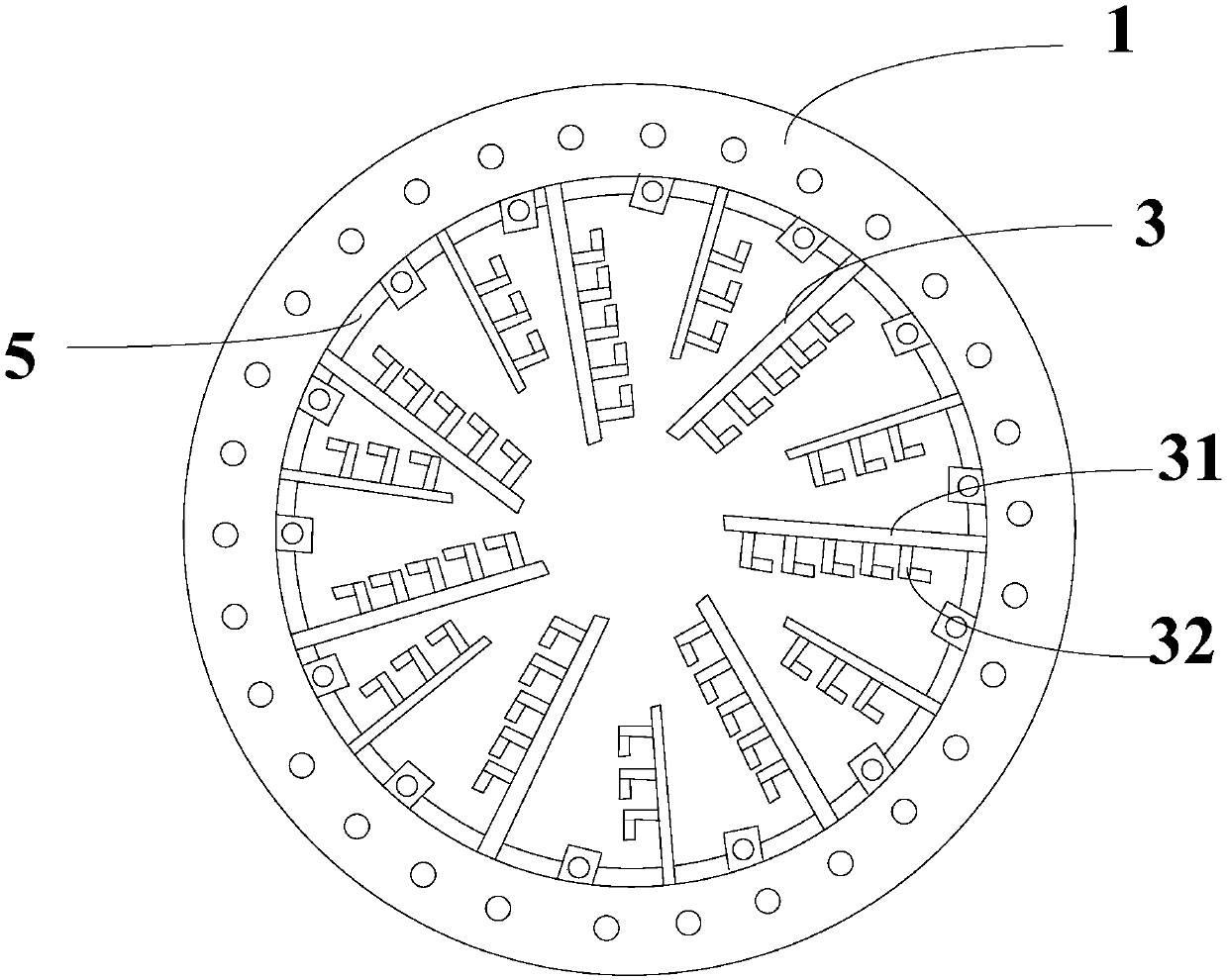

Roller type heat exchange equipment capable of being used for n-tert-butyl acrylamide production

PendingCN109654834AIncrease the heat exchange areaImprove drying efficiencyDrying gas arrangementsDrying chambers/containersPulp and paper industryTert butyl

The invention relates to roller type heat exchange equipment. The roller type heat exchange equipment comprises a roller which is horizontally arranged, is supported on a base through a supporting roller, and is rotatably connected relative to the base, a plurality of groups of heat exchange tubes which are horizontally arranged in the roller, and an inlet and an outlet for a heat exchange medium,wherein when the roller is in on a still position, a charge hole is formed in the top of the roller, and a discharge hole is formed in the bottom of the roller; a gas inlet is formed in one side endsurface, in the axial direction, of the roller, and a gas exhaust hole is formed in the other side end surface, in the axial direction, of the roller; sides of each group of heat exchange tubes are hung on the roller wall of the roller, and the other sides of each group of the heat exchange tubes are free ends; the heat exchange tubes extend by certain length in the roller or extend to the other end of the roller from one end of the roller; the inlet and the outlet are formed in the roller; the inlet communicates with ends of each group of heat exchange tubes through branch pipelines arrangedin the roller; and the outlet communicates with a pipeline which is jointed with the other ends of each group of heat exchange tubes. The roller type heat exchange equipment increases a heat exchangearea in the roller, and improves drying efficiency.

Owner:HEFEI ALL PLUS ENVIRONMENTAL TECH CO LTD

Low phosphorus scale inhibitor for reverse osmosis membranes for reuse of reclaimed water

InactiveCN108854564AGood water quality scale inhibition and dispersion effectStrong adaptability to water qualitySemi-permeable membranesReverse osmosis plantTert butyl

The invention relates to the technical field of water treatment, in particular to a low phosphorus scale inhibitor for reverse osmosis membranes for reuse of reclaimed water. The low phosphorus scaleinhibitor is a composition prepared by compounding an acrylic acid-sulfonated styrene copolymer, a methacrylic acid-acrylate copolymer, an acrylic acid-2-acrylamide-2-methacrylic acid-N-tert-butyl acrylamide copolymer and N-xanthogenated chitosan. The low-phosphorus scale inhibitor provided by the invention has good scale inhibition and dispersion effects on the water quality of the reclaimed water, is very excellent in scale inhibition and dispersion effects, can guarantee the normal and efficient operation of a reverse osmosis system, has high adaptability to the complex water quality of thereclaimed water, and can prevent sewage blocking and scaling of the reverse osmosis system in a process of treating the reclaimed water; furthermore, the low-phosphorus scale inhibitor provided by the invention adopts a low-phosphorus formula, and the compounding materials are cheap and easy to obtain, and the preparation is simple. The low phosphorus scale inhibitor can enable the total phosphorus content of the concentrated water to be lower than the requirement of the national standard for the total phosphorus in disposal sewerage, thereby reducing the subsequent treatment cost of an enterprise.

Owner:史怀国

Macromolecule inorganic composite nanosphere supported Ni-B catalyst and preparation method and application thereof

InactiveCN104014375AEasy to separateHigh reactivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionMetal catalystEmulsion polymerization

The invention provides a macromolecule inorganic composite nanosphere supported Ni-B catalyst and a preparation method and application thereof. The preparation method comprises the following steps: with N-isopropyl acrylamide, 2-acrylamide-2-methylacrylsulfonate, and N-tert-butylacrylamide as comonomers, an N,N'-methylene bisacrylamide as a crosslinking agent and potassium persulphate as an initiator, synthesizing a terpolymer by a soap-free emulsion polymerization method, centrifuging and drying; dispersing a defined amount of terpolymer in ethanol, pouring in a titanium tetrabutoxide ethanol solution, ultrasonically treating, centrifuging and drying; and dispersing composite nanospheres in a nickel-plated solution for chemical nickel-plating to obtain the macromolecule inorganic composite nanosphere supported Ni-B catalyst. According to the preparation method, a macromolecule material and an inorganic material are compounded and then supported to the metal catalyst, no agglomeration of the metal catalyst in a reaction process can be ensured, and the reaction activity can be effectively improved.

Owner:SHAOXING UNIVERSITY

Application of terpolymer nanosphere loaded Ni-B catalyst to sodium borohydride catalysis and hydrolysis hydrogen generation reaction

InactiveCN106006551AEasy to separateHigh reactivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionPotassium persulfateSynthesis methods

Owner:GAOYOU CITY ORGANIC CHEM FACOTRY

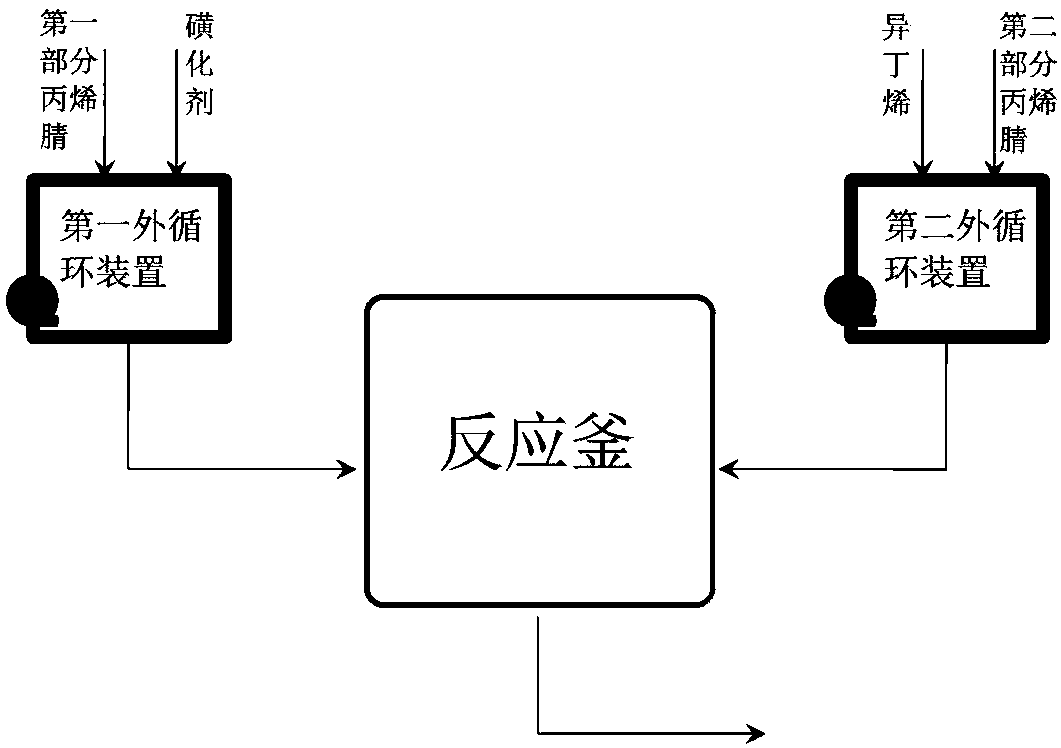

Method for producing tert-butyl acryloyl sulfonic acid

InactiveCN108017562AReduce generationImprove uniformityOrganic compound preparationSulfonic acid preparationAcrylonitrileSlurry

The invention provides a method for producing tert-butyl acryloyl sulfonic acid. The method includes providing of a first external circulation device and a second external circulation device, adding of a first portion of acrylonitrile and a sulfonating agent into the first external circulation device to form a first mixture, and adding of a second portion of the acrylonitrile and isobutylene intothe second external circulation device to form a second mixture; mixing of the first mixture from the first external circulation device and the second mixture from the second external circulation device in a reaction kettle for reacting to produce tert-butylacryloyl sulfonic acid slurry; transferring of the tert-butylacryloyl sulfonic acid slurry to a maturation tank for maturation to produce maturated tert-butylacryloyl sulfonic acid slurry; solid-liquid separation of the maturated tert-butylacryloyl sulfonic acid slurry, and vacuum drying of a separated solid to obtain crude tert-butyl acryloyl sulfonic acid. The method can effectively reduce the formation of by-products and increase production efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com