Anticorrosive agent and anticorrosive method

An anti-corrosion agent and anti-corrosion technology, which is applied in the field of anti-corrosion agents and anti-corrosion, can solve problems such as corrosion, and achieve the effect of preventing corrosion and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

[0038] Hereinafter, examples and comparative examples of the present invention will be described.

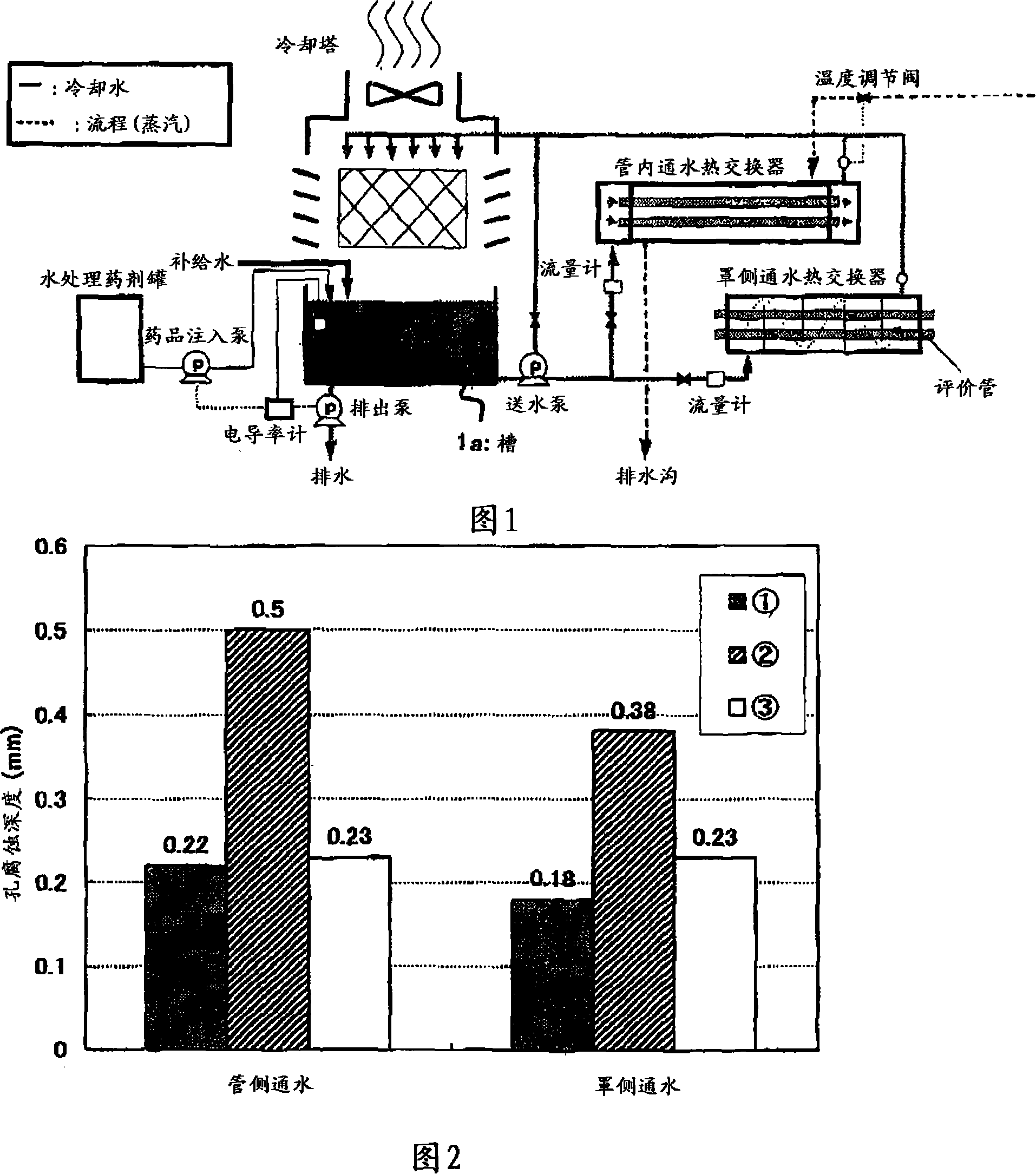

[0039] Fig. 1 shows a test device for evaluation.

[0040] In Fig. 1, a cooling tower 1 having a tank 1a at the bottom is installed, and the test water flows from the tank to the hood-side water-passing heat exchanger 2 provided with the evaluation tube and the in-pipe water-passing heat exchanger provided with the evaluation tube. water. The test water passed through each heat exchanger is returned to the cooling tower 1, and recycled after cooling. Make-up water is added to the evaporated part. In each heat exchanger, steam is supplied as a heat source. In addition, the water treatment chemicals used in the examples and comparative examples were supplied from the water treatment chemical tank 4 to the tank 1a.

[0041] In this test device, the flow rate of water passing through the pipe side is set to 0.3m / s, steam heating is implemented, and the temperature difference bet...

Embodiment 2 and comparative example 2

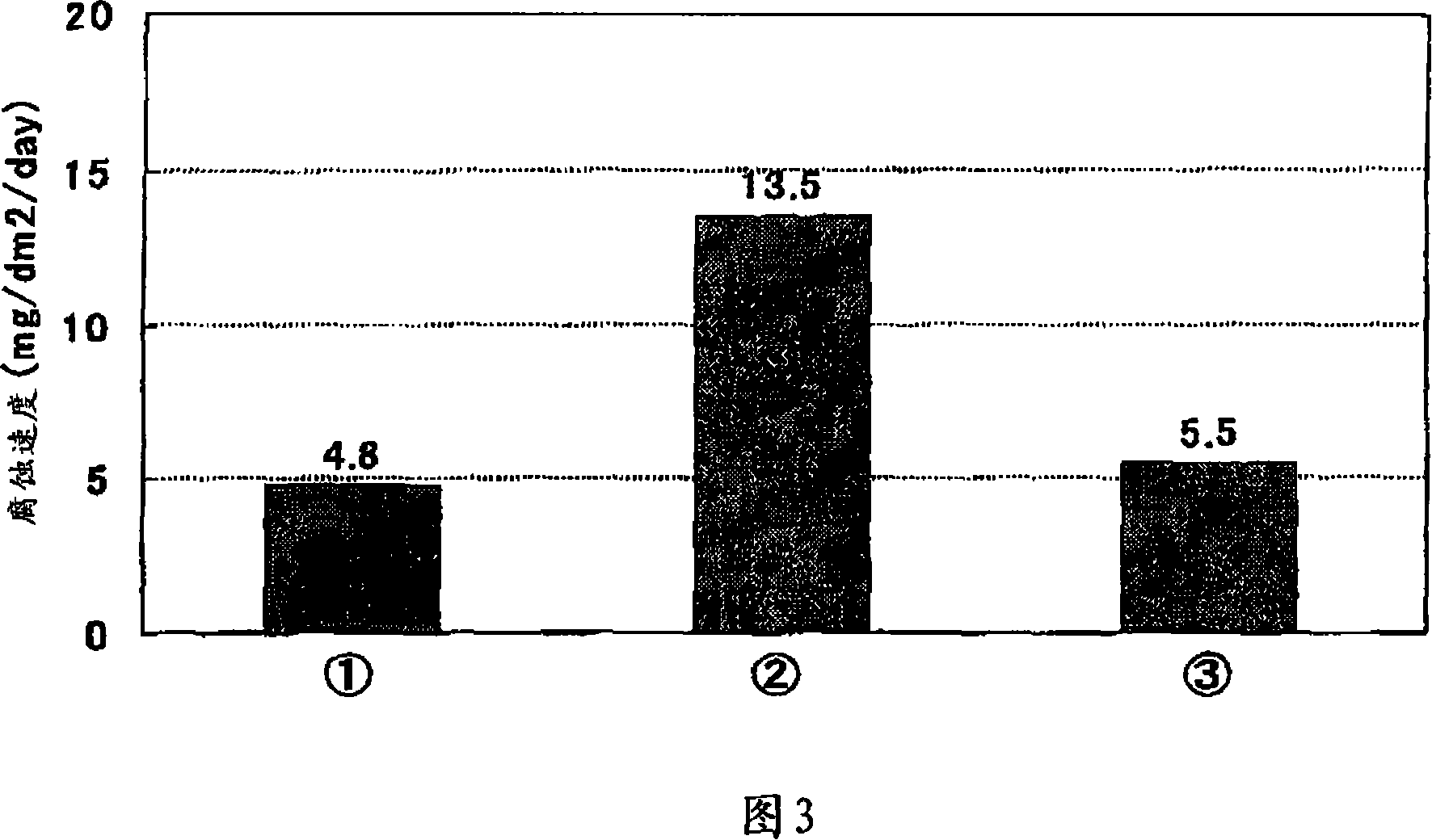

[0048] A rotating disk corrosion test in a 1 L beaker was carried out. The test water was implemented based on city water in the oak area, and the water temperature was 50° C., the stirring speed: 150 rpm, and the test was carried out for 1 week. The pre-weight of the SPCC used for the test was measured in advance, and the corrosion rate was calculated from the difference from the weight after the test. The medicine that is used for test is identical with above-mentioned embodiment 1) phosphorus-zinc series medicine, 2) non-phosphorus non-metal treatment medicine, 3) anti-pitting corrosion agent of the present invention, and the addition of each medicine is also identical with above-mentioned embodiment.

[0049] The results are shown in Figure 3.

[0050] As can be seen from Fig. 3, even in the rotating disc corrosion test, compared with the non-phosphorus non-metallic treatment chemical treatment, the anti-corrosion of the present invention, especially the anti-corrosion ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com