Preparation method of high-efficient copolymer silicon scale inhibitor

A technology of copolymer and scale inhibitor, which is applied in the field of preparation of high-efficiency copolymer silica scale inhibitor, which can solve the problems of single scale inhibitor performance, limited application and development, eutrophication of water body, etc., and achieve in-situ deoxidation ability High, strong regeneration ability, good adsorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

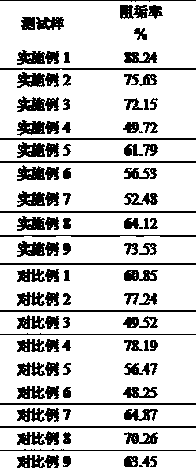

Examples

Embodiment 1

[0010] 1) Dissolve 40 parts of acrylic acid and 40 parts of 2-acrylamido-2-methylpropanesulfonic acid in 200 parts by weight of deionized water and mix well, add alkaline reagents to adjust the pH to 7~8, and then add 20 parts N-tert-butylacrylamide, stir evenly, add 0.2 parts of disodium edetate to the mixed monomer solution, and transfer the mixed solution into the reaction kettle after completely dissolving;

[0011] 2) Take 0.3 parts by weight of the active agent urea nitrate, dissolve them in 10 parts by weight of deionized water to make a solution, and set aside; add the modified activated carbon fiber material to the reaction kettle while stirring, then fill in nitrogen, and heat the solution to 70 ℃, slowly and alternately add the active agent into the reaction kettle, the dropwise addition is completed within 80 minutes, the temperature is raised to 85 ℃ and the reaction is kept at a constant temperature for 2 hours, and the reaction is stopped and cooled to room tempe...

Embodiment 2

[0015] It is exactly the same as Example 1, except that 45 parts of acrylic acid, 45 parts of 2-acrylamido-2-methylpropanesulfonic acid, and 10 parts of N-tert-butylacrylamide are added.

Embodiment 3

[0017] It is exactly the same as Example 1, except that 35 parts of acrylic acid, 35 parts of 2-acrylamido-2-methylpropanesulfonic acid, and 30 parts of N-tert-butylacrylamide are added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com