Macromolecule inorganic composite nanosphere supported Ni-B catalyst and preparation method and application thereof

An inorganic composite and nanosphere technology, applied in the field of material science, can solve the problems of carrier rupture, catalyst activity decline, active metal shedding, etc., and achieve the effects of easy separation, high hydrogen yield, and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

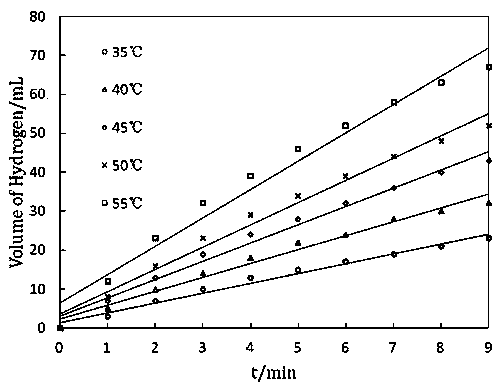

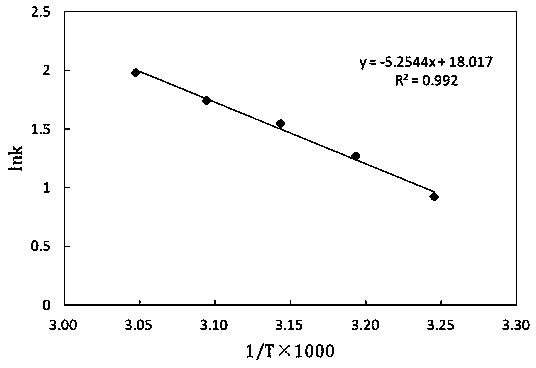

Examples

Embodiment 1

[0033] Preparation of Ni-B catalyst

[0034] 1. Preparation of terpolymer nanospheres:

[0035] Weigh 1.13g N-isopropylacrylamide (NIPAM), 0.104g 2-acrylamide-2-methylpropanesulfonic acid (AMPS), 0.254g N-tert-butylacrylamide (NtBAM), 0.046g N,N Add 45mL of distilled water to a 100mL three-neck flask, stir and dissolve at 70°C under nitrogen atmosphere, then add 5mL aqueous solution containing 0.053g of potassium persulfate, continue to pass through nitrogen for 10min, then close and seal the reaction 5h. The reacted emulsion is centrifuged, dried and set aside.

[0036] 2. Preparation of composite nanospheres:

[0037] Weigh 0.2g of the dried terpolymer and disperse it in 30mL of ethanol to obtain emulsion a; pipette 1mL of n-butyl titanate (TBOT) into 19mL of ethanol, stir vigorously for 5min to obtain solution b. Transfer the a emulsion to the b solution, sonicate for 30 minutes, centrifuge, transfer to a petri dish, place at 35°C for 12h, and then dry at 80°C for 3h to...

Embodiment 2

[0041] The preparation method is the same as in Example 1, except that in the preparation of the Ni-B catalyst, the amount of sodium borohydride used in the nickel plating solution is changed to 0.1 g.

Embodiment 3

[0043] The preparation method is the same as in Example 1, except that in the preparation of the Ni-B catalyst, the amount of sodium borohydride used in the nickel plating solution is changed to 0.2 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com