Thermally-induced physical cross-linked colored hydrogel and preparation method thereof

A physical crosslinking and hydrogel technology, which is applied in the field of thermally induced physical crosslinking color hydrogel and its preparation, can solve the problems of cumbersome preparation process, non-reversibility, irreversible sol-gel process, etc. To achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

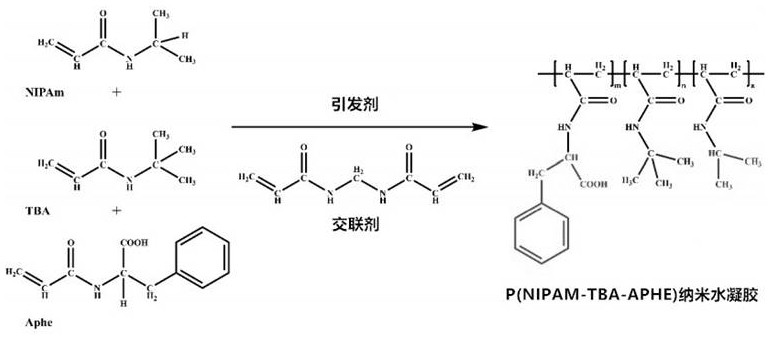

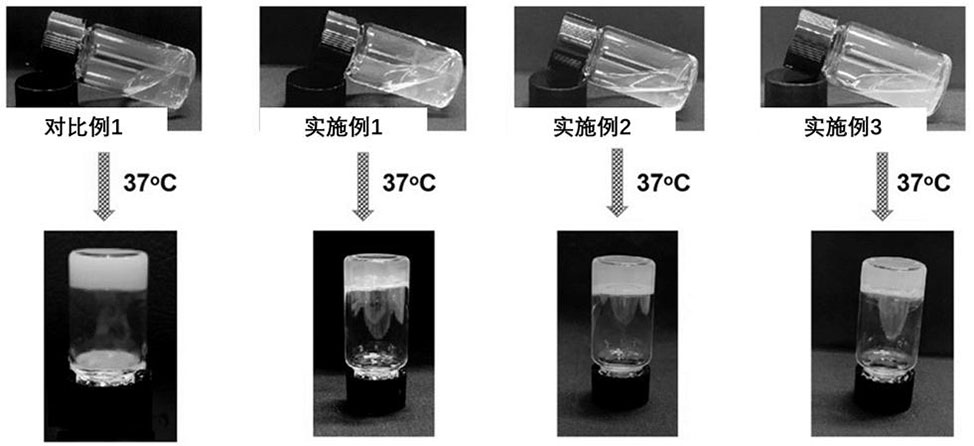

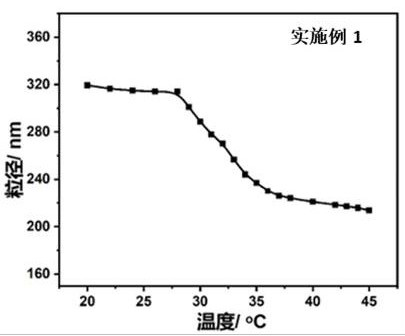

[0031] Examples 1-9 are examples of preparation of P(NIPAm-TBA-Aphe) copolymerized nano-hydrogels of the present invention. Through thermally induced physical crosslinking, a macroscopic jelly-like colored hydrogel is obtained and has reversibility.

Embodiment 1

[0054] Take about 0.9231g monomeric N-isopropylacrylamide (NIPAm), 0.1526g monomeric N-tert-butylacrylamide, 0.0962g monomeric L-N-propionylphenylalanine (Aphe), 0.0295g crosslinker Dissolve N,N'-methylenebisacrylamide, 0.0408g emulsifier sodium lauryl sulfate in 95 ml deionized water, and bubble N at room temperature 2 Deoxygenation, magnetic stirring for 30 minutes;

[0055] The reaction temperature was raised to 70 °C, and under N 2 Keep warm for 30 minutes under protection;

[0056] Then about 0.0679 g of initiator ammonium persulfate was dissolved in 5 ml of deionized water, and added to the above solution, keeping N 2 atmosphere, continue to react for 4 hours;

[0057] Then soak the obtained reactant in deionized water and dialyze for 7 days, change the water three times a day to remove residual reaction raw materials and electrolytes in the reaction system. The molecular weight cut-off of the dialysis bag used is 8000-14000. That is, P (NIPAm-TBA-Aphe) ternary copo...

Embodiment 2

[0063] Take about 0.9062g monomeric N-isopropylacrylamide (NIPAm), 0.1512g monomeric N-tert-butylacrylamide, 0.1298g monomeric L-N-propionylphenylalanine (Aphe), 0.0306g crosslinker Dissolve N,N'-methylene bisacrylamide, 0.0398g emulsifier sodium lauryl sulfate in 95 ml deionized water, and bubble N at room temperature 2 Deoxygenation, magnetic stirring for 30 minutes;

[0064] The reaction temperature was raised to 70 °C, and under N 2 Keep warm for 30 minutes under protection;

[0065] Then about 0.0615 g of initiator ammonium persulfate was dissolved in 5 ml of deionized water, and added to the above solution, keeping N 2 atmosphere, continue to react for 4 hours;

[0066] Then soak the obtained reactant in deionized water and dialyze for 7 days, change the water three times a day to remove residual reaction raw materials and electrolytes in the reaction system. The molecular weight cut-off of the dialysis bag used is 8000-14000. That is, P (NIPAm-TBA-Aphe) ternary cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com