Silica scale inhibitor, preparation method and application

A technology of scale inhibitor and silica scale, which is applied in the direction of scale removal and water softening, chemical instruments and methods, natural water treatment, etc., can solve the problems of high production cost and complicated preparation process, and achieve high utilization rate and simple synthesis process , The effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

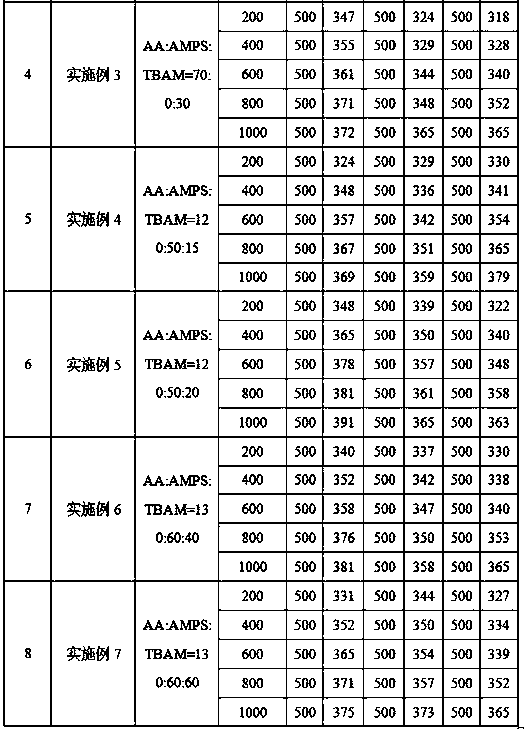

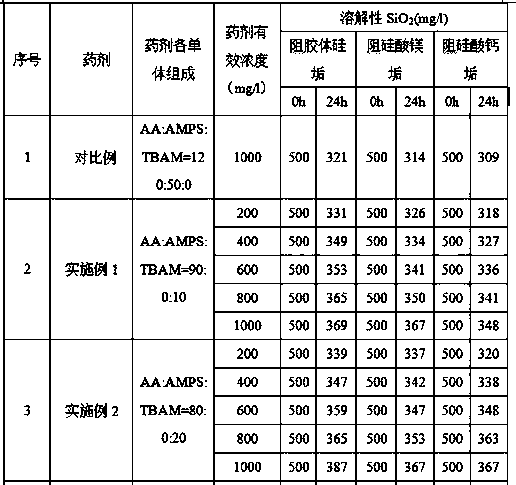

Examples

Embodiment 1

[0024] Add 90 parts of acrylic acid, 10 parts of N-tert-butylacrylamide and 180 parts of deionized water into the reaction kettle in sequence, stir and raise the temperature to 70±2°C, and start to add sodium persulfate and sodium hypophosphite dropwise, among which sodium persulfate The weight ratio of sodium hypophosphite and comonomer is 1:55, and the weight ratio of sodium hypophosphite and comonomer is 1:18. At the same time, sodium hydroxide is added dropwise to control the pH of the solution between 3 and 4, and the temperature is kept at 70°C for 65 minutes. Finally, the silica scale antiscalant is obtained, the viscosity average molecular weight is 4830, and the molecular weight distribution is 3.1~3.8.

Embodiment 2

[0026] Add 80 parts of acrylic acid, 20 parts of N-tert-butylacrylamide and 160 parts of deionized water into the reaction kettle in sequence, stir and raise the temperature to 70±2°C, start to add sodium persulfate and sodium hypophosphite dropwise, among which sodium persulfate The weight ratio of sodium hypophosphite and comonomer is 1:54, and the weight ratio of sodium hypophosphite and comonomer is 1:17. At the same time, sodium hydroxide is added dropwise to control the pH of the solution between 3 and 4, and the temperature is kept at 68°C for 60 minutes. Finally, the silica scale antiscalant was obtained, with a viscosity-average molecular weight of 5347 and a molecular weight distribution of 3.3-4.0.

Embodiment 3

[0028] Add 70 parts of acrylic acid, 30 parts of N-tert-butylacrylamide and 140 parts of deionized water into the reaction kettle in sequence, stir and raise the temperature to 70±2°C, and start to add sodium persulfate and sodium hypophosphite dropwise, among which sodium persulfate The weight ratio of sodium hypophosphite and comonomer is 1:58, and the weight ratio of sodium hypophosphite and comonomer is 1:17. At the same time, sodium hydroxide is added dropwise to control the pH of the solution between 3 and 4, and the temperature is kept at 70°C for 60 minutes. Finally, the silica scale antiscalant is obtained, the viscosity average molecular weight is 5182, and the molecular weight distribution is 3.1~3.7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com