Combined production method

A technology of mixture and mixing temperature, applied in chemical instruments and methods, preparation of organic compounds, preparation of sulfonic acid, etc., can solve problems such as no co-production method, achieve resource saving, high yield and purity, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

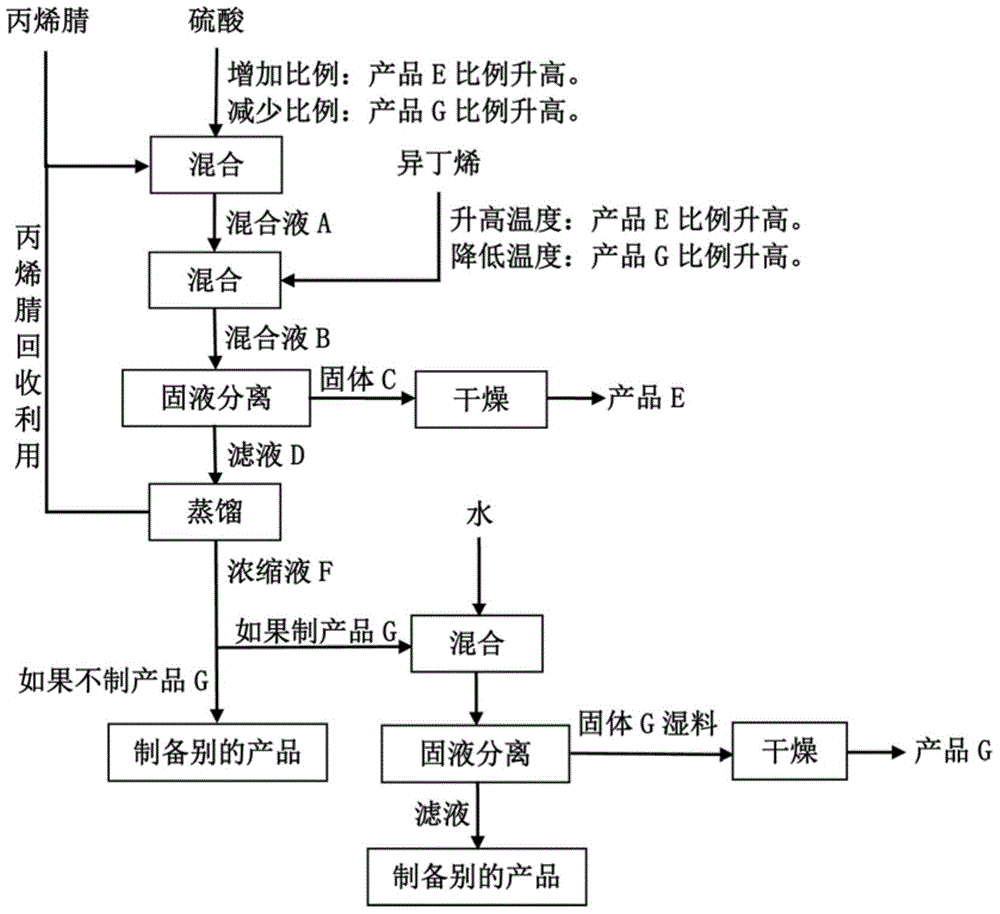

[0022] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 Shown, coproduction method of the present invention comprises the following steps:

[0024] (1) Fully mix acrylonitrile and concentrated sulfuric acid at a weight ratio of 5:1-2 to obtain mixture A. If the proportion of concentrated sulfuric acid is increased in the mixing ratio of acrylonitrile and concentrated sulfuric acid, the 2-acrylamide group in the final product will - The proportion of 2-methylpropanesulfonic acid increases, if the proportion of concentrated sulfuric acid is reduced, the proportion of product E in the final product increases; the mixing temperature of acrylonitrile and concentrated sulfuric acid is -5°C-20°C, the preferred mixing temperature It is 10°C-15°C.

[0025] (2) Fully mix mixture A and isobutene at a weight ratio of 13:1-3 to obtain mixture B with solid precipitation; the mixing temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com