Modifier for polycarboxylate-type water reducer for concrete and preparation method of modifier

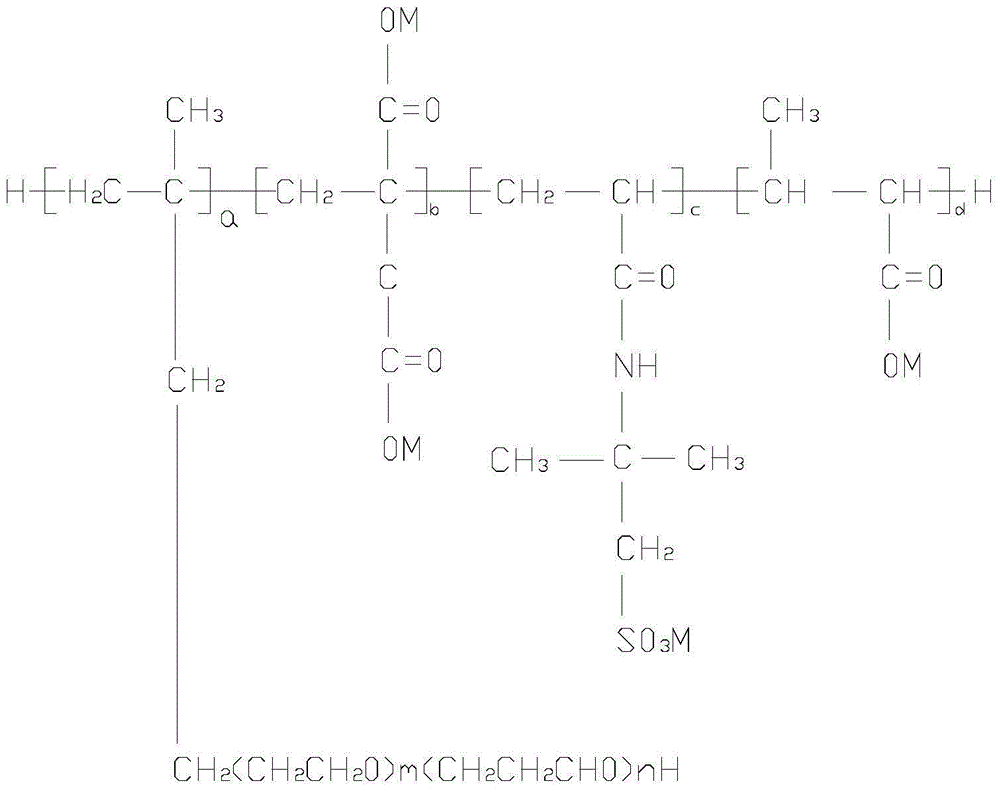

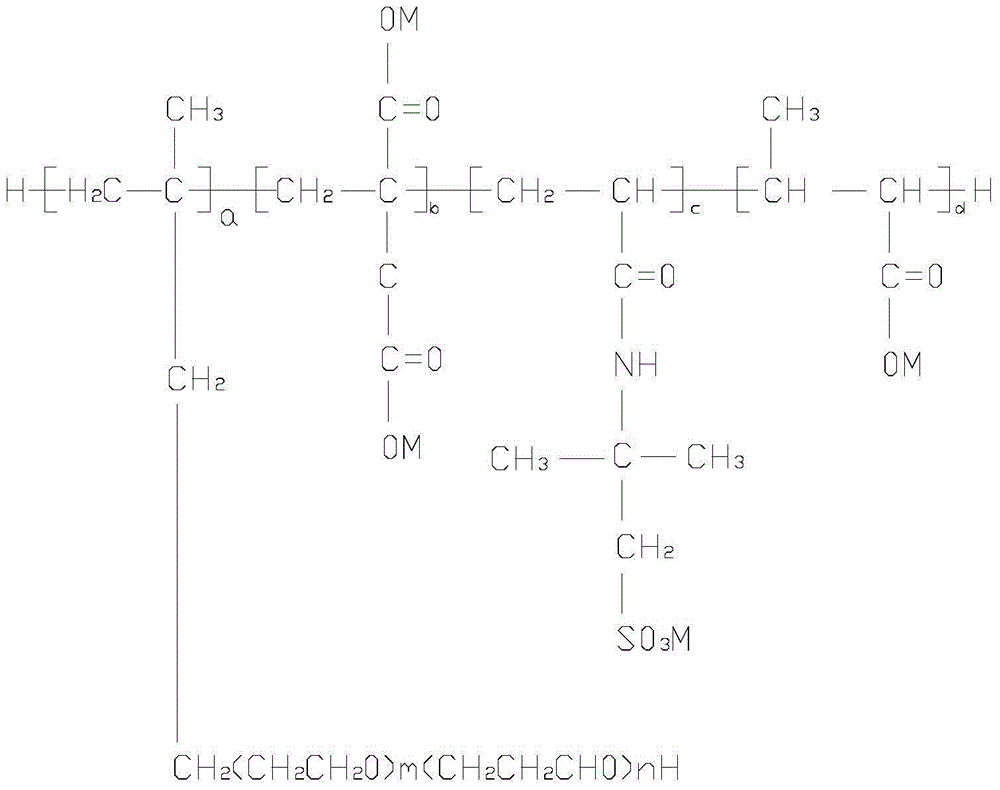

The technology of a polycarboxylic acid system and a regulator is applied in the field of concrete admixtures, which can solve problems such as uneven quality, and achieve the effects of improving slump retention performance, simple raw material formulation, and good slump retention performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

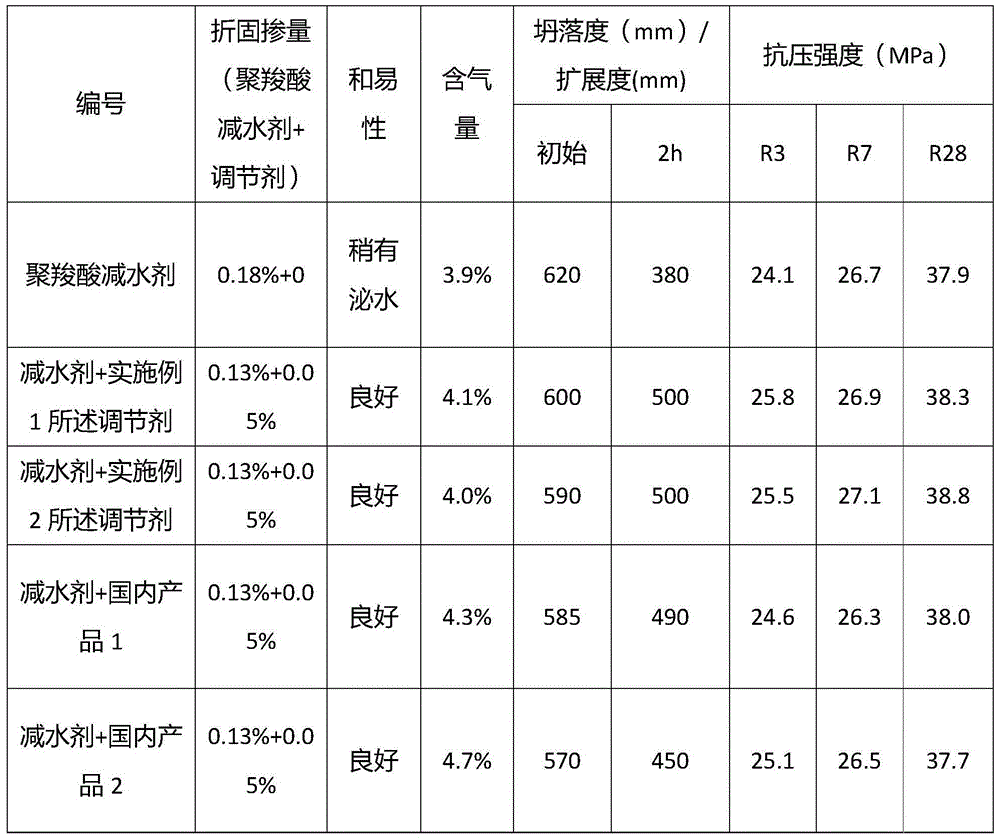

Examples

Embodiment 1

[0028] Prepare the regulator for concrete polycarboxylate water reducer according to the following raw material quantity and process

[0029] Material preparation:

[0030] Add 3g of azobisisobutamidine hydrochloride and 2.5g of trisodium phosphate into 55g of deionized water, mix well, which is material A; add 7.8g of crotonic acid, 15.1g of tert-butylacrylamide sulfonic acid, and add 30g to remove Ionized water, mixed evenly, is B material;

[0031] polymerization:

[0032] Add 125 g of deionized water, 175 g of polyethylene glycol prenyl ether and 10.8 g of itaconic anhydride to a glass reactor equipped with a thermometer and an electric mixer, stir to dissolve and heat to 30°C, adding a mass concentration of 30% Add 3.5g of hydrogen peroxide. After stirring evenly, first add material A, and then add material B at the same time after 5 minutes, add material A for 3 hours, add material B for 2.5 hours, and keep the temperature for 0.5 hours after the addition of material A. Cool d...

Embodiment 2

[0035] Prepare the regulator for concrete polycarboxylate water reducer according to the following raw material quantity and process

[0036] Material preparation:

[0037] Add 3.2g of azobisisobutamidine hydrochloride and 2.6g of trisodium phosphate into 52g of deionized water, mix well, it is material A; add 9.5g of crotonic acid, 18.1g of tert-butylacrylamide sulfonic acid, and add 31g Mix well in deionized water, it is B material;

[0038] polymerization:

[0039] Add 122g of deionized water, 175g of polyethylene glycol isoamyl ether and 7.1g of itaconic anhydride to a glass reactor equipped with a thermometer and an electric mixer, stir to dissolve and heat to 30 degrees, adding a mass concentration of 30% 3.8g of hydrogen peroxide, stir evenly, first add material A, and then add material B at the same time after 5 minutes, add material A for 3 hours, add material B for 2.5 hours, and keep the temperature for 1 hour after the addition of material A. To below 45 degrees, neutral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com