Method for extracting N-tert-butyl acrylamide

A technology of tert-butyl acrylamide and an extraction method, applied in the field of fine chemistry, can solve the problems of low extraction purity, material waste, low yield of N-tert-butyl acrylamide process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

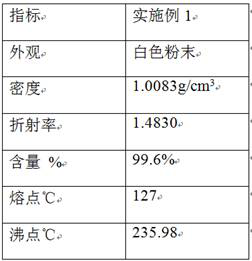

Embodiment 1

[0019] Embodiment 1 A kind of N-tert-butylacrylamide extraction method

[0020] Step 1. Raw material preparation

[0021] The raw material used is the residue produced during the production of 2-acrylamido-2-methylpropanesulfonic acid. The residue components include 55% tert-butylacrylamide, 6% acrylamide, 2-acrylamide - 20% of 2-methylpropanesulfonic acid, 14% of methacrylsulfonic acid, and 5% of copolymer, and the percentages are mass percentages.

[0022] Step 2, prepare crude product

[0023] The still residue and water are mixed according to the mass ratio of 1:3, and stirred to form a slurry; the slurry is separated by pressure filtration, the air pressure is 2.5KPa, the feed volume of the filter press is 80% of the volume of the filter press, and the filter cake contains The amount of water is less than 15%, and the filtrate is neutralized by reacting with sodium hydroxide, and then goes to the water treatment device for treatment.

[0024] The filter cake is crude N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com