Method for controlling vertical lift and horizontal movement of working cab of aerial work platform

A high-altitude work platform, horizontal movement technology, applied in the direction of lifting device, etc., can solve problems such as difficulty in ensuring accuracy and difficulty in realization, and achieve the effects of convenient operation, improved work efficiency, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

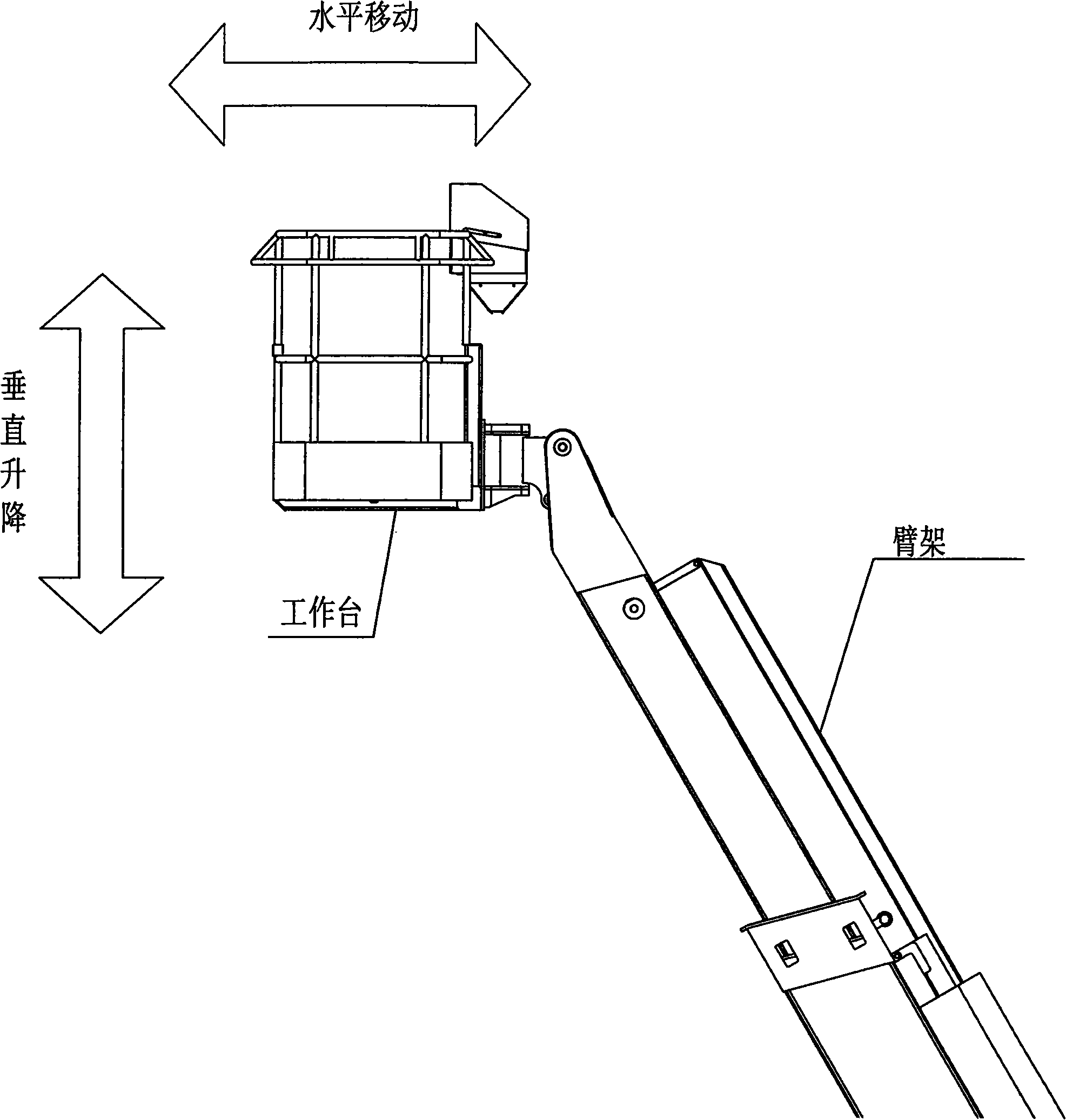

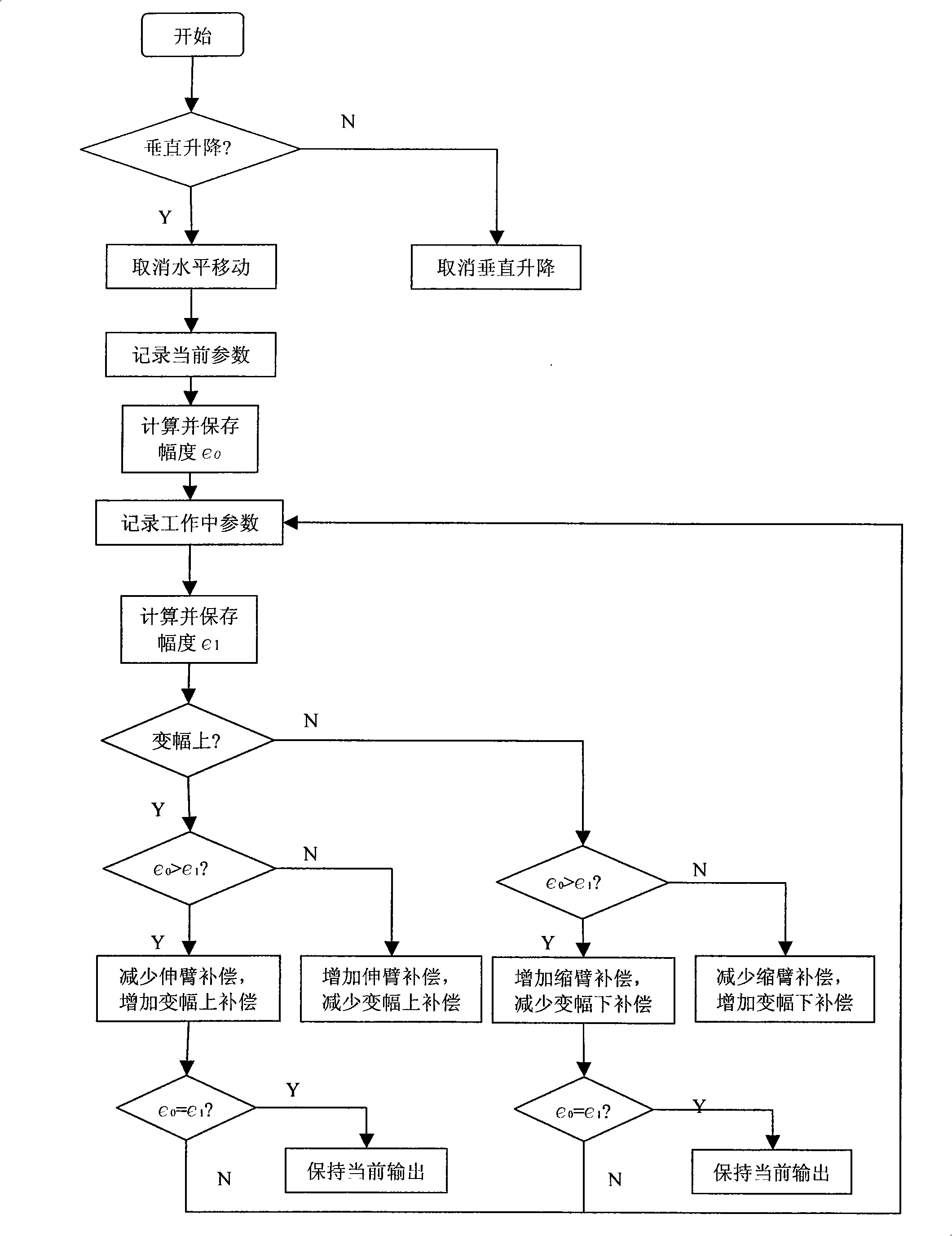

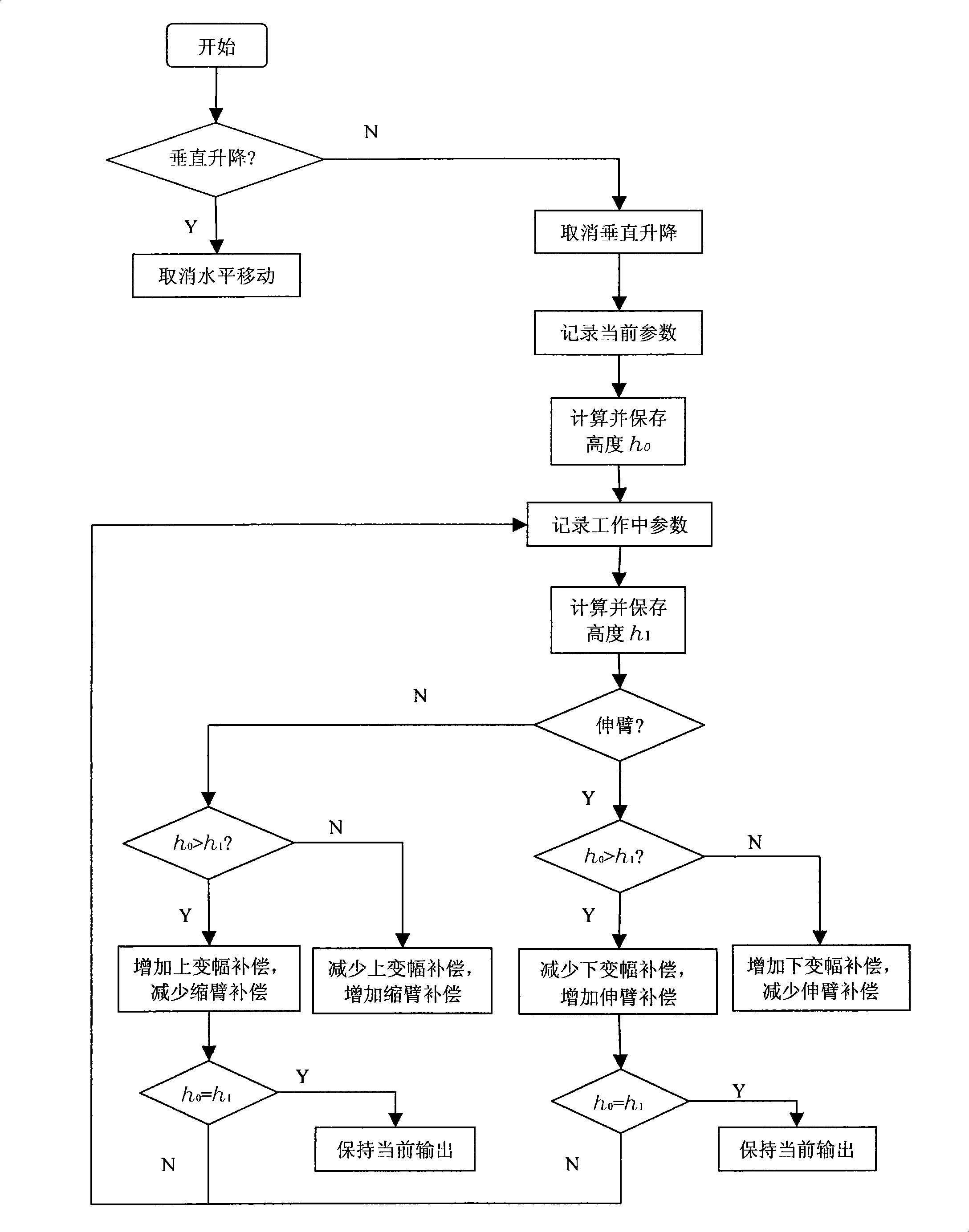

[0011] The invention relates to a control method for vertical lifting and horizontal movement of a work bucket of an aerial work platform. The aerial work platform is composed of three parts: a chassis, a platform and an arm frame, wherein the heights of the chassis and the platform are fixed. The method is as follows: a length sensor and an angle sensor are installed on the jib to detect the current state of the jib of the aerial work platform and transmit it to the controller. When the function of "vertical lift and horizontal movement" needs to be realized, turn on the switch. When the staff operates the luffing handle, the luffing and stretching will be output at a certain ratio at the beginning, and this value can be adjusted. The controller is based on the current state - arm length l 0 with angle θ 0 Calculate its magnitude e 0 , and record, where e 0 = l 0 ×Cosθ 0 . During the working process of the boom, the sensor continuously transmits the working parameters o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com