Display apparatus and its assembling method

A technology for display devices and assembly methods, which is applied in the directions of identification devices, optics, instruments, etc., can solve the problems of complicated assembly procedures and increased material costs, and achieve the effect of reducing the complexity of assembly procedures and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above content of the present invention more obvious and understandable, the following preferred embodiments are specifically cited below, and in conjunction with the accompanying drawings, the detailed description is as follows:

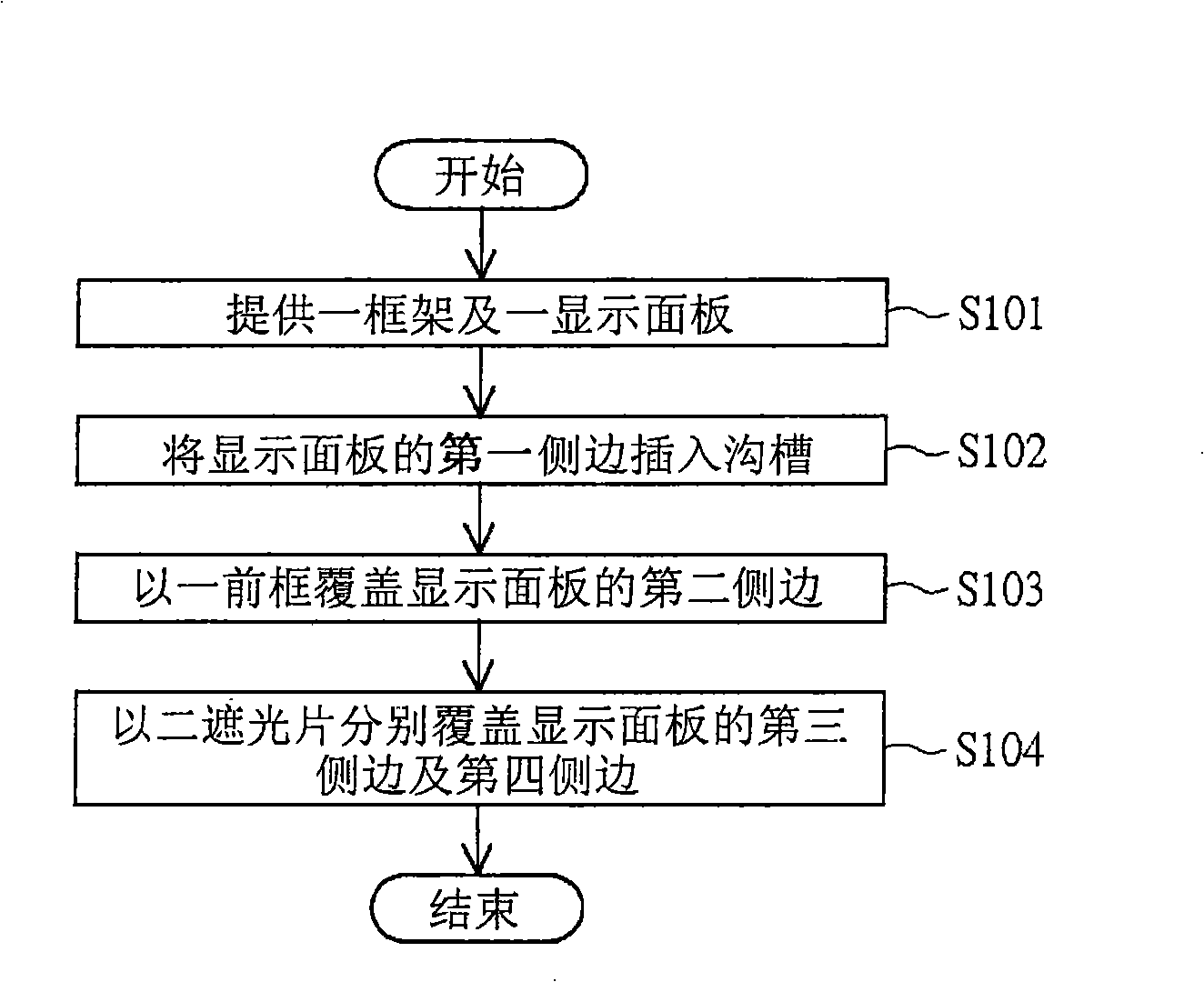

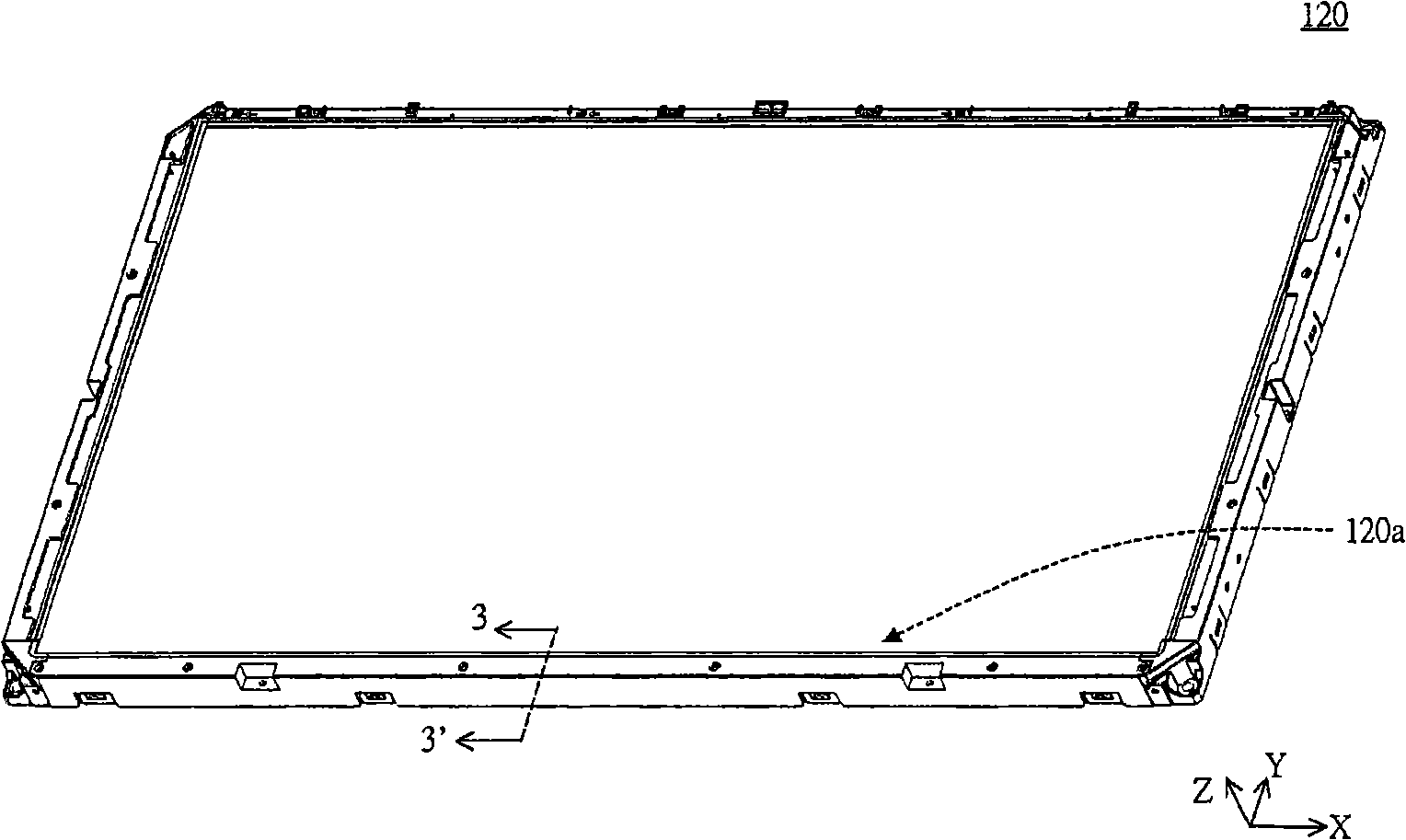

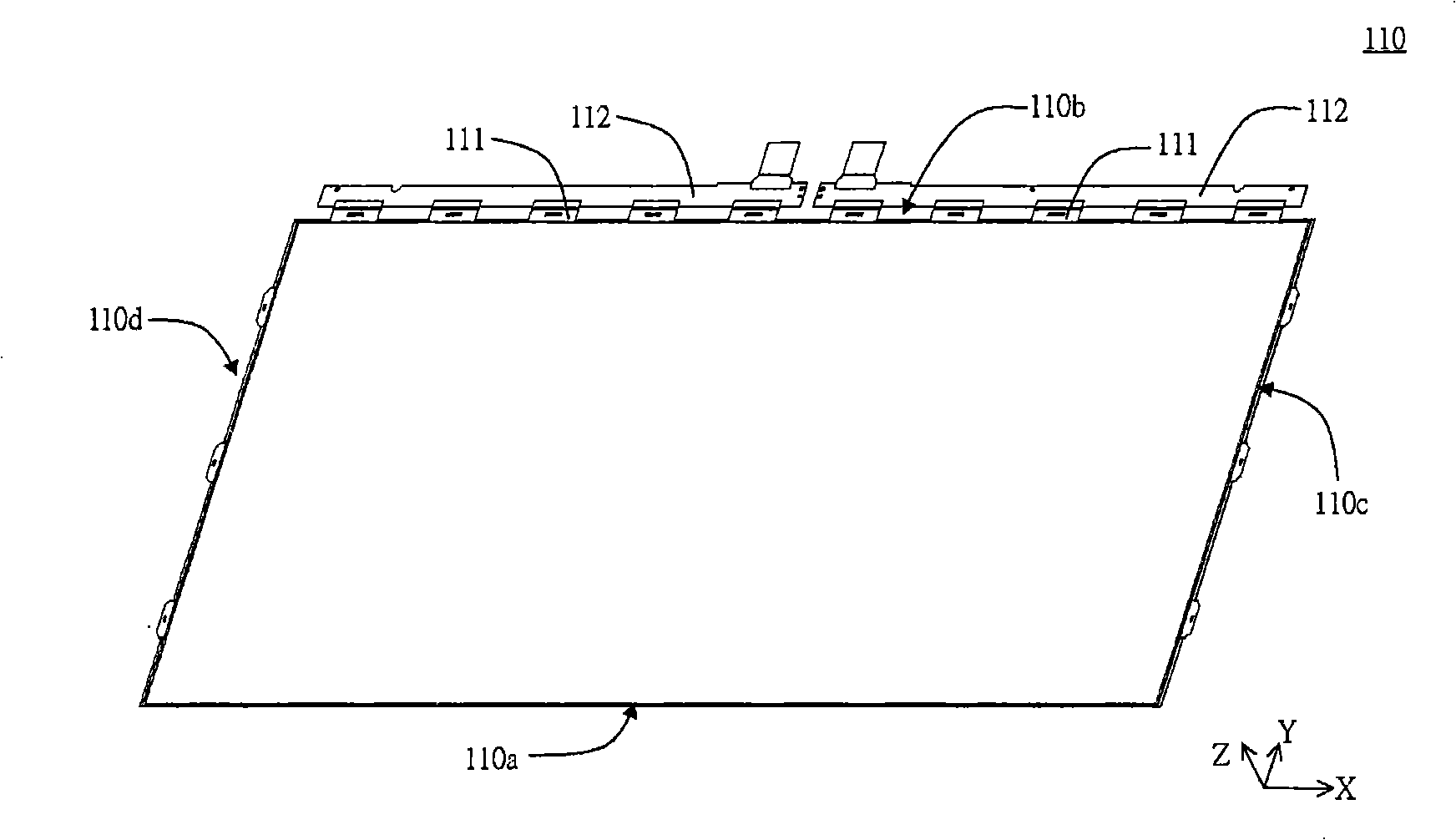

[0027] Please refer to figure 1 and Figure 2A to Figure 2D , figure 1 It is a flowchart of a manufacturing method of the display device 100 according to a preferred embodiment of the present invention, Figure 2A to Figure 2D for figure 1 A schematic diagram of the steps. First, if Figure 2A and Figure 2B As shown, in step S101, the frame 120 and the display panel 110 are provided.

[0028] Please also refer to Figure 2A and image 3 , image 3 for Figure 2A The cross-sectional view of the frame 120 along the section line 3-3'. In terms of the structure of the frame 120, the frame 120 has a groove 120a. Depend on Figure 2A From the point of view, the groove 120a is disposed inside the frame 120, so the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com