Apparatus and method for dislodging and extracting solid materials from tubes

A technology of solid materials and pipes, applied in the direction of cleaning methods, chemical instruments and methods, cleaning methods and utensils using gas flow, etc., and can solve the problems that are not disclosed or raised.

Inactive Publication Date: 2008-11-26

ROHM & HAAS CO

View PDF21 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The method is carried out using equipment techniques similar to those described above using only vacuum, so no method or equipment is disclosed or suggested for loosening dense solid material without damaging the reactor tubes or the solid material itself

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

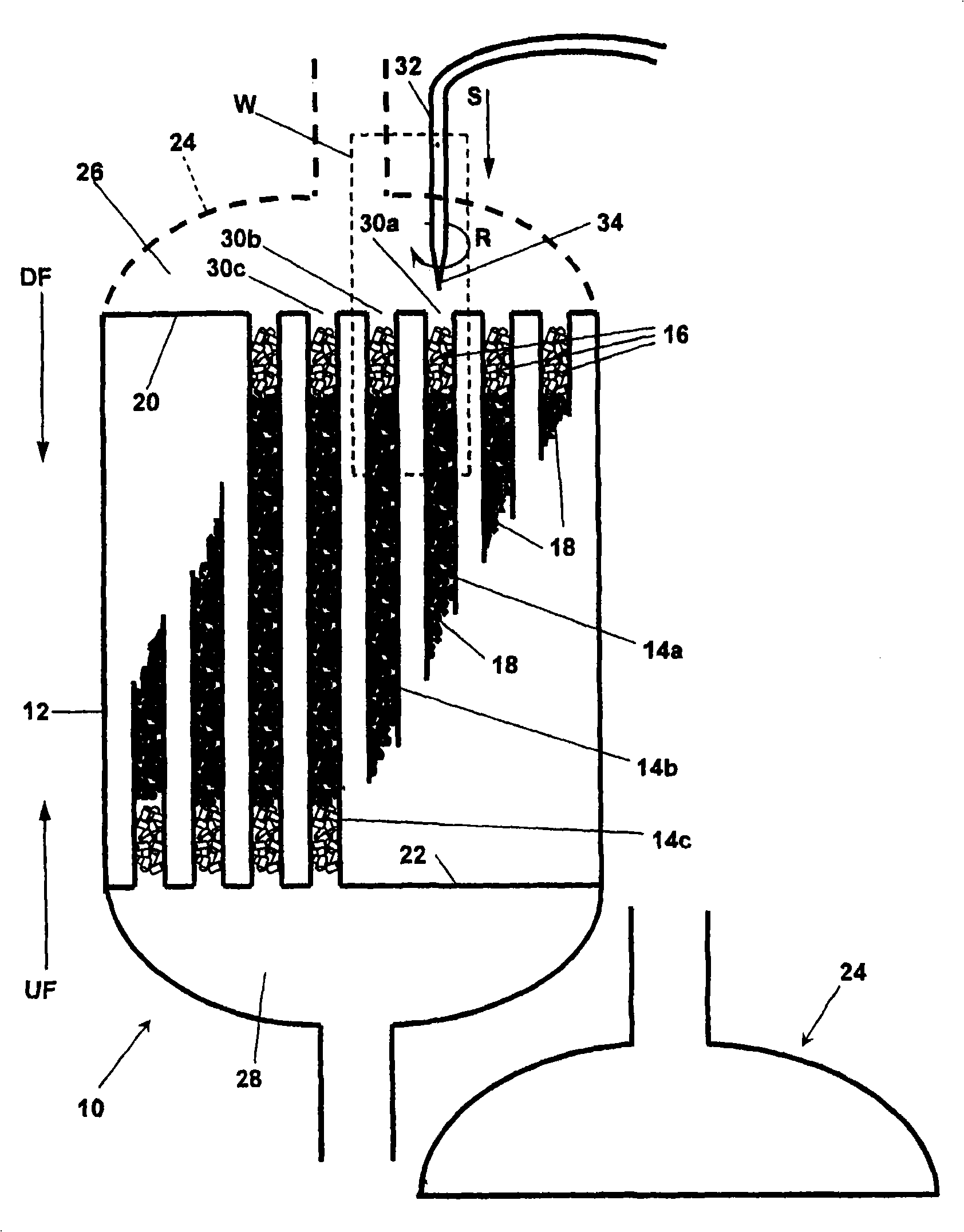

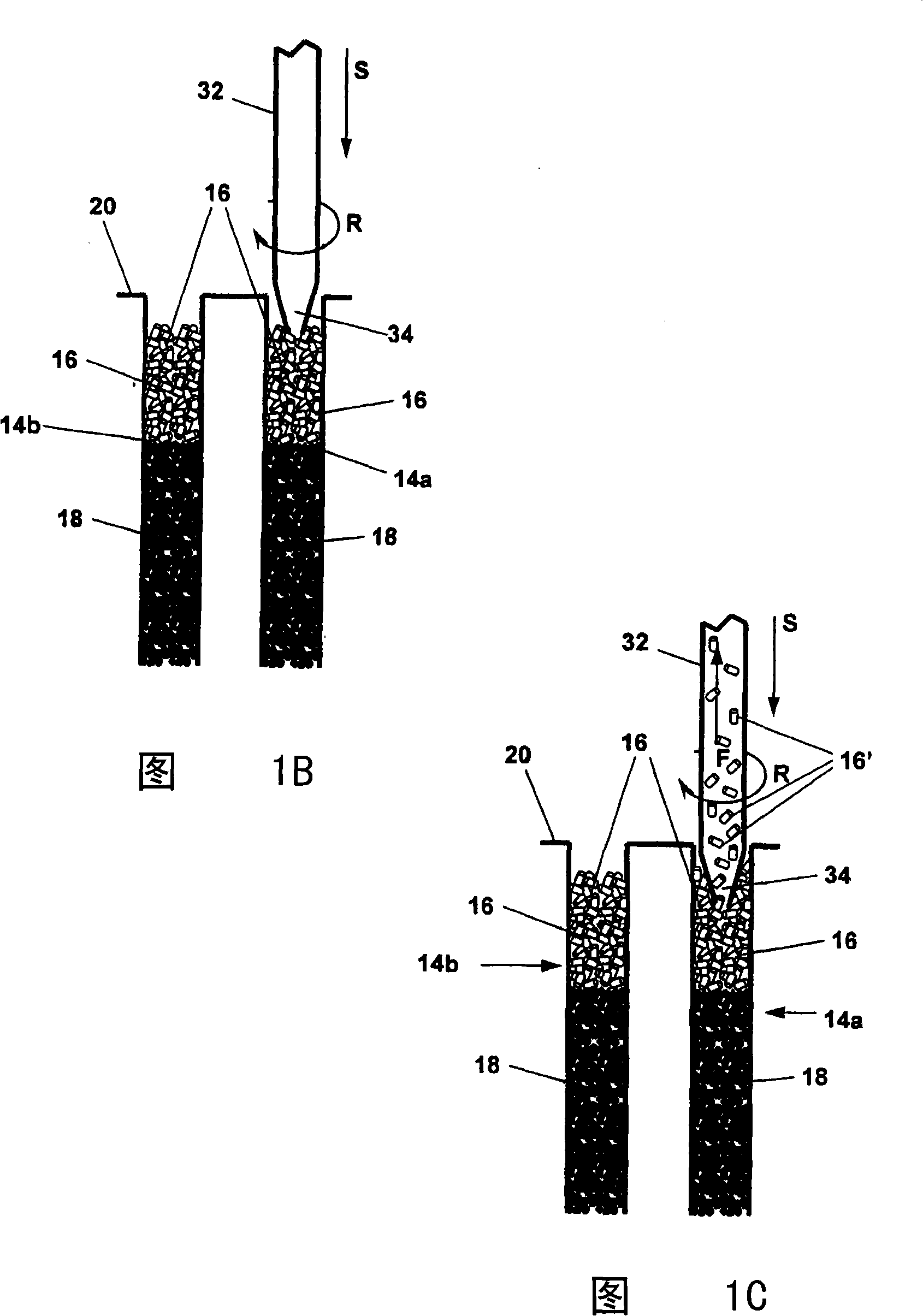

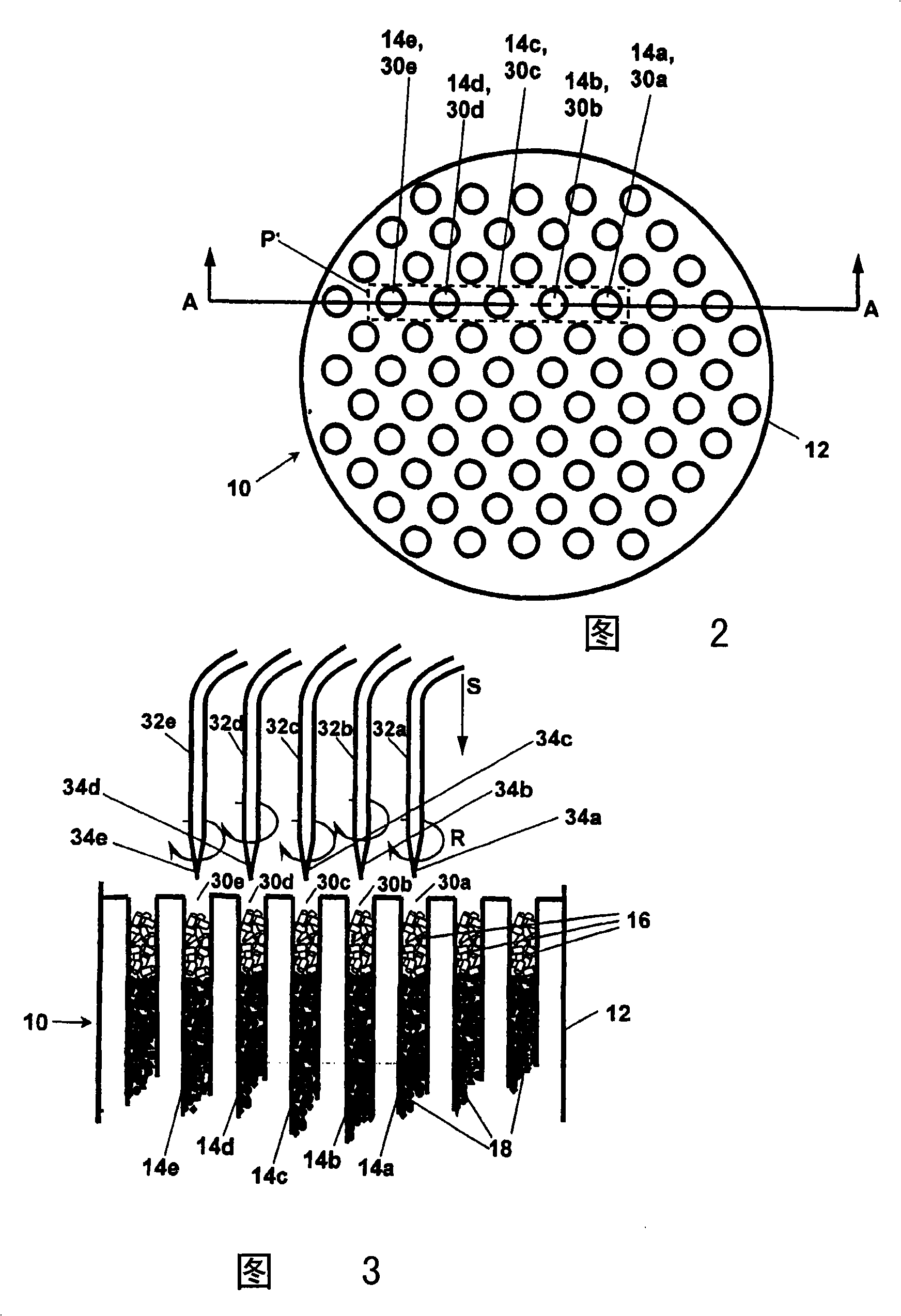

The invention provides an apparatus and method for efficiently dislodging and extracting a portion of solid materials from one or a plurality of reactor tubes of shell-and-tube reactors without damage to at least a portion of the solid materials which would make the solid materials unsuitable for reuse. The apparatus has at least one rod, a rotator assembly for rotating the rod, and a transmission assembly for applying an axial force to insert the rod into a corresponding reactor tube and dislodging solid materials therein. The rod is also in fluid communication with an aspirator for extraction of the dislodged solid materials. The method comprises the following steps of: inserting one or a plurality of rods into corresponding reactor tubes, dislodging at least a portion of the solid materials, while minimizing damage to the solid materials or the tubes by rotating and applying the axial force to the rods as the rods contact with the solid materials. The dislodged solid materials are then extracted from the reactor tubes.

Description

Apparatus and method for loosening and extracting solid material from pipes technical field The present invention relates to methods for effectively dislodging and extracting at least a portion of solid material from one or more reactor tubes of a shell and tube reactor while minimizing damage to said solid material and Methods and apparatus for leaving at least a portion of solid material structurally suitable for reuse. The invention also relates to a method of monitoring and communicating the status of said pipe during removal and replacement of said solid material. Background technique There are situations where, for various reasons, solid material needs to be removed from the tubular part without damage to the tubular part or the solid material being possible. For example, shell and tube heat exchangers are used as reactor vessels for conducting chemical reaction processes. Such reactors, when operated on an industrial scale, typically have a very large number (eg ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J8/00B01J8/06

CPCB01J8/0025B01J8/0045B01J8/06B01J2208/00761B08B5/04

Inventor M·S·德库西N·Q·李S·M·斯旺

Owner ROHM & HAAS CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com