Magnetic flow switch, for aspirators in particular

A technology of flow switch and magnetic flow, which is applied in the direction of magnetic/electric field switch, electric switch, grinding/polishing safety device, etc., and can solve problems such as wear, damage, and hindering spring operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

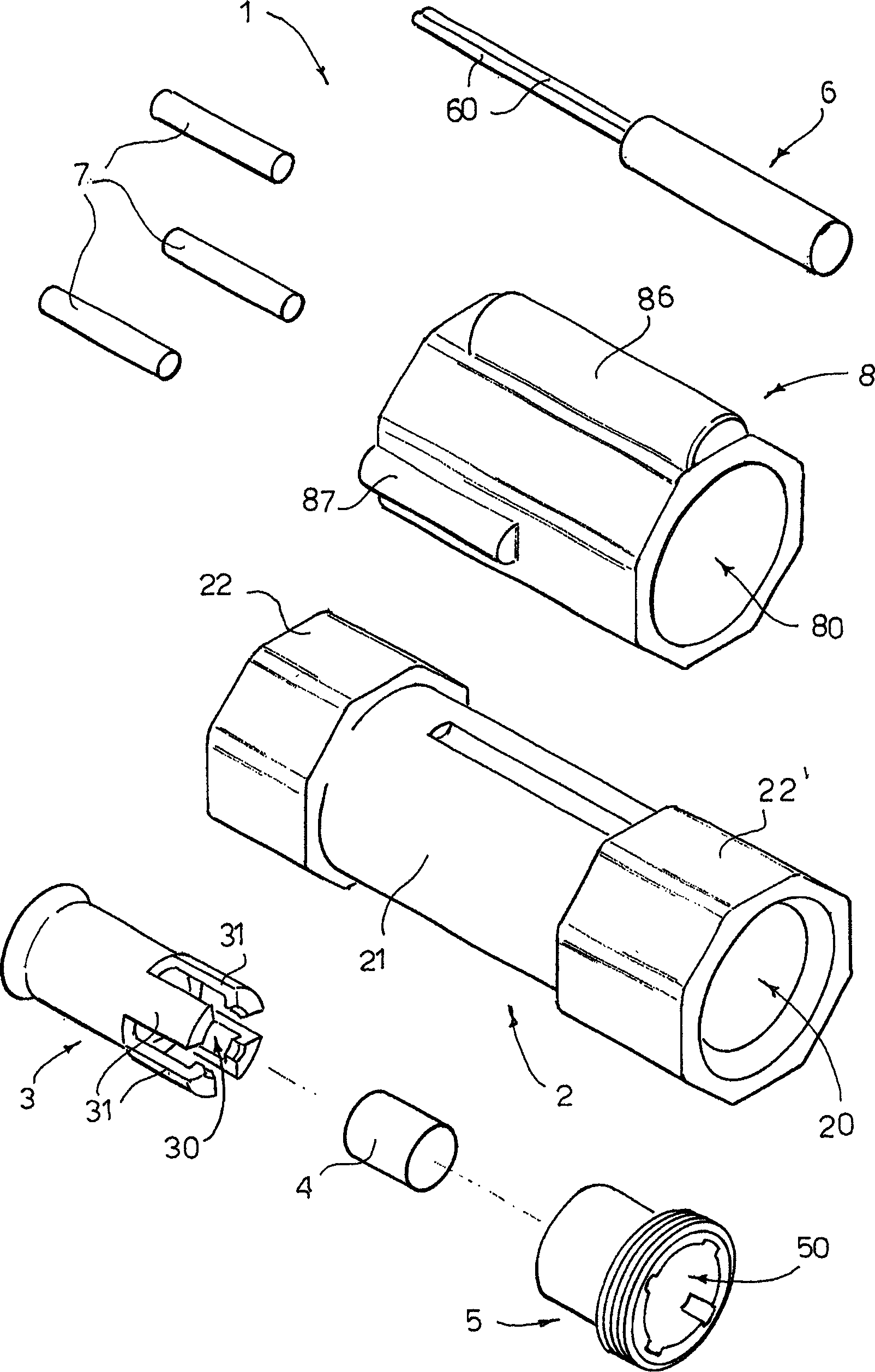

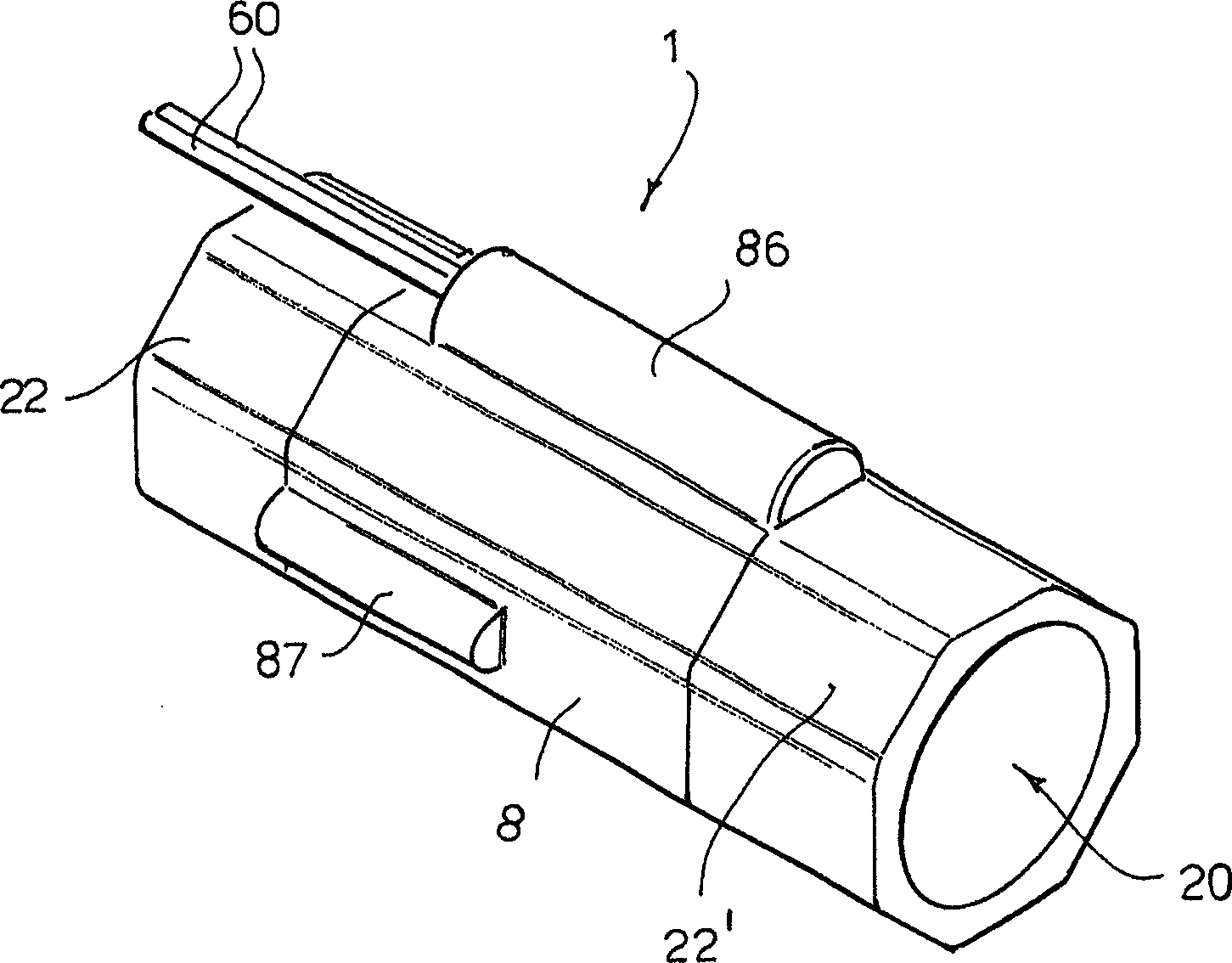

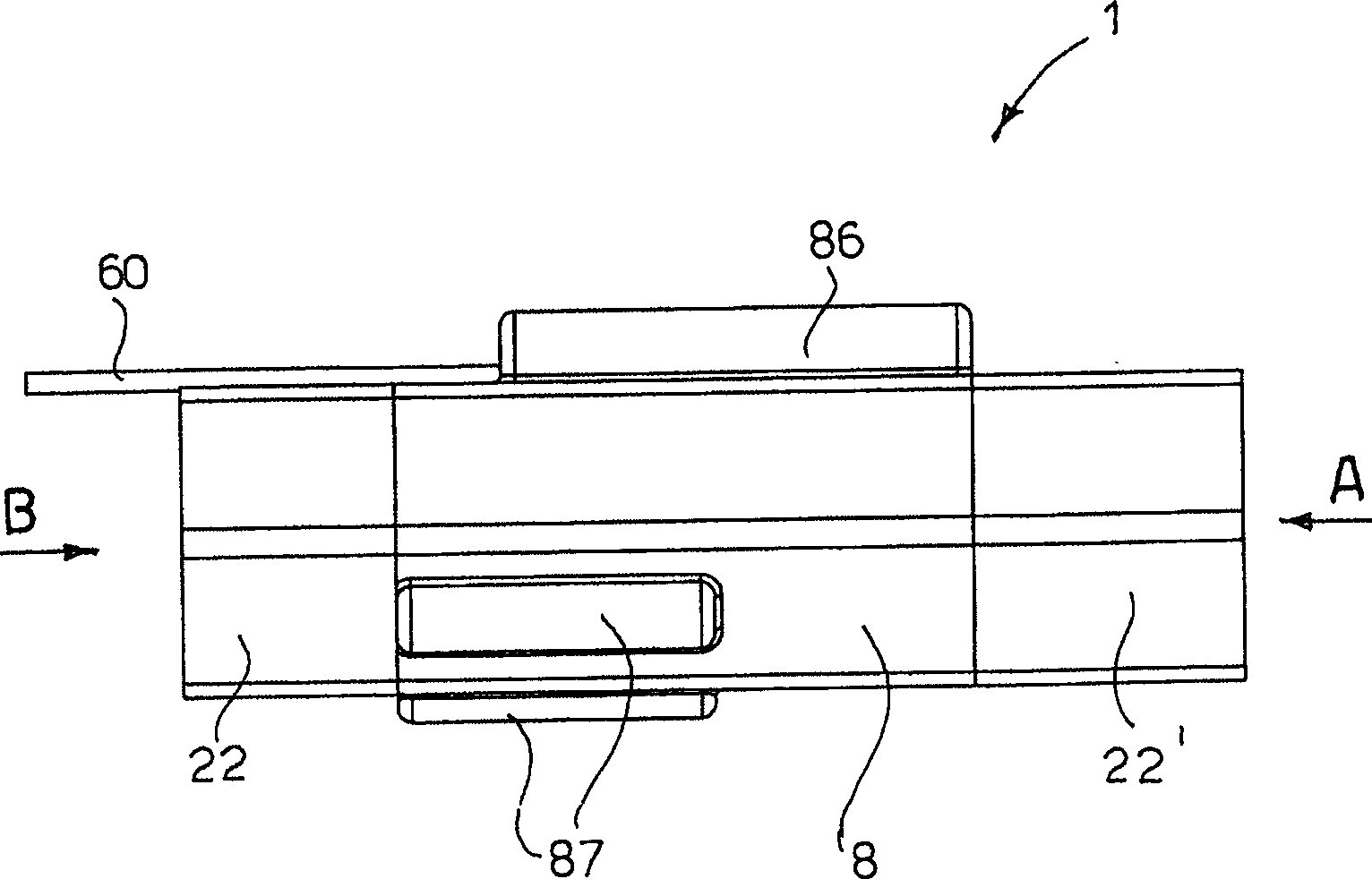

[0031] The flow switch according to the present invention, represented as a whole by the reference numeral 1, will be Figures 1 to 7 described with the help of .

[0032] The flow switch 1 comprises an internally hollow body 2 provided with a substantially cylindrical axially penetrating chamber 20 . The body 2 of the flow switch comprises a middle part 21 with a cylindrical outer side between two ends 22 and 22', wherein the two ends have the shape of a hexagon nut adapted to engage with a hexagon wrench of type "20" . The hexagonal shape of the ends 22, 22' is specially chosen so that the flow switch 1 can be accommodated in a suction device commonly available on the market.

[0033] For clarity, the hexagonal portion of the front end (ie the fluid inlet portion) is designated by the reference numeral 22, and the hexagonal portion of the rear end (ie the fluid outlet portion) is designated by the reference numeral 22'. Thus, in the following, the terms "front end" a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com