A bearing in connection with a boom

A technology of bearings and sliding bearings, which is applied in the direction of linear motion bearings, bearings, shafts and bearings, can solve problems affecting the positioning accuracy of rock drilling machines, and achieve the effect of saving money in processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Several embodiments of the present invention will be described below on the basis of the accompanying drawings.

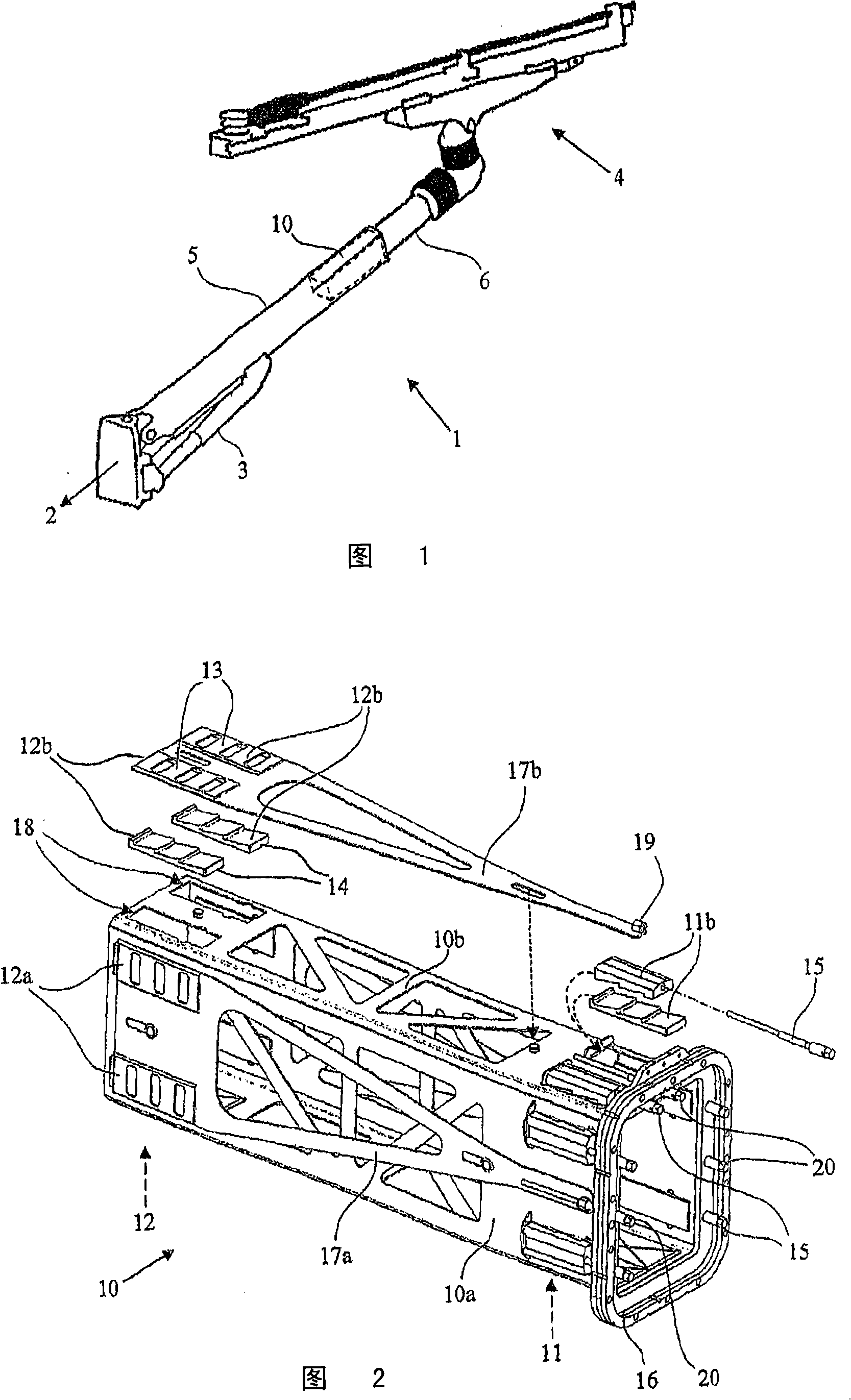

[0027] Figure 1 shows one field of application of a support according to one aspect of the invention. A boom 1 of the type according to the invention is flexibly arranged (or configured) in relation to a carrying device 2 for the boom. The working cylinder body 3 is flexibly connected with the carrying device 2 and the cantilever, so that the cantilever 1 is vertical. At the end of the boom 1 an example of a rock drilling rig 4 operated by the boom 1 is shown. The rock drilling equipment is of a known type and it will not be described further here.

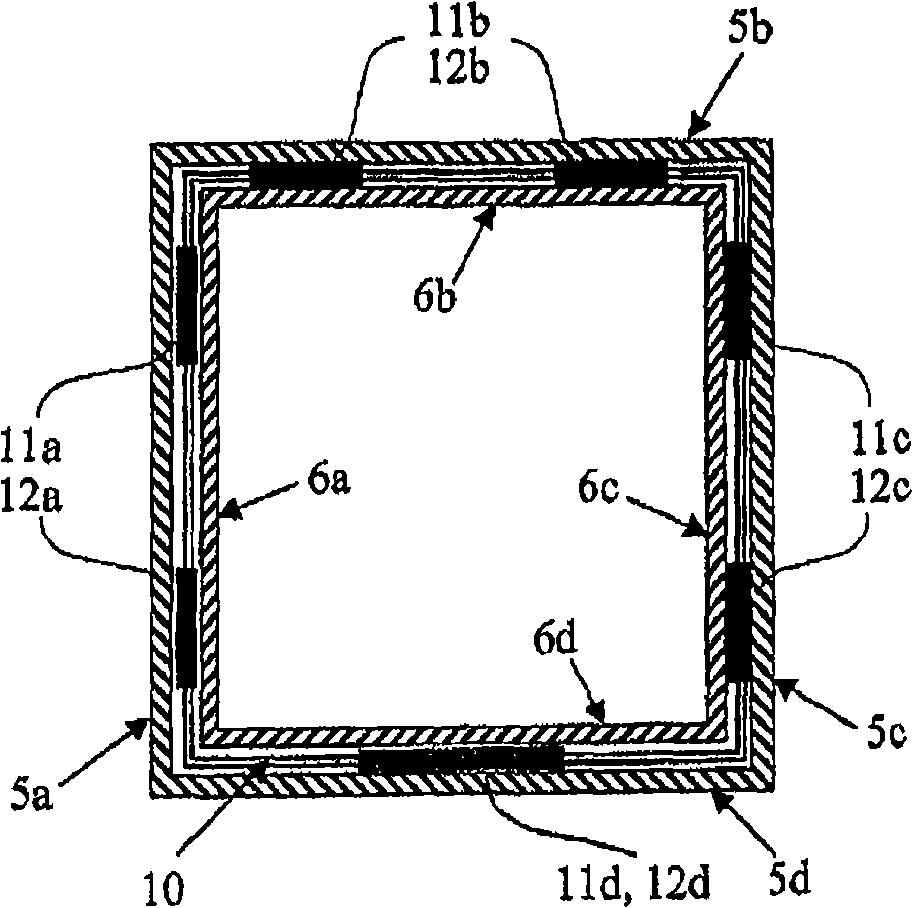

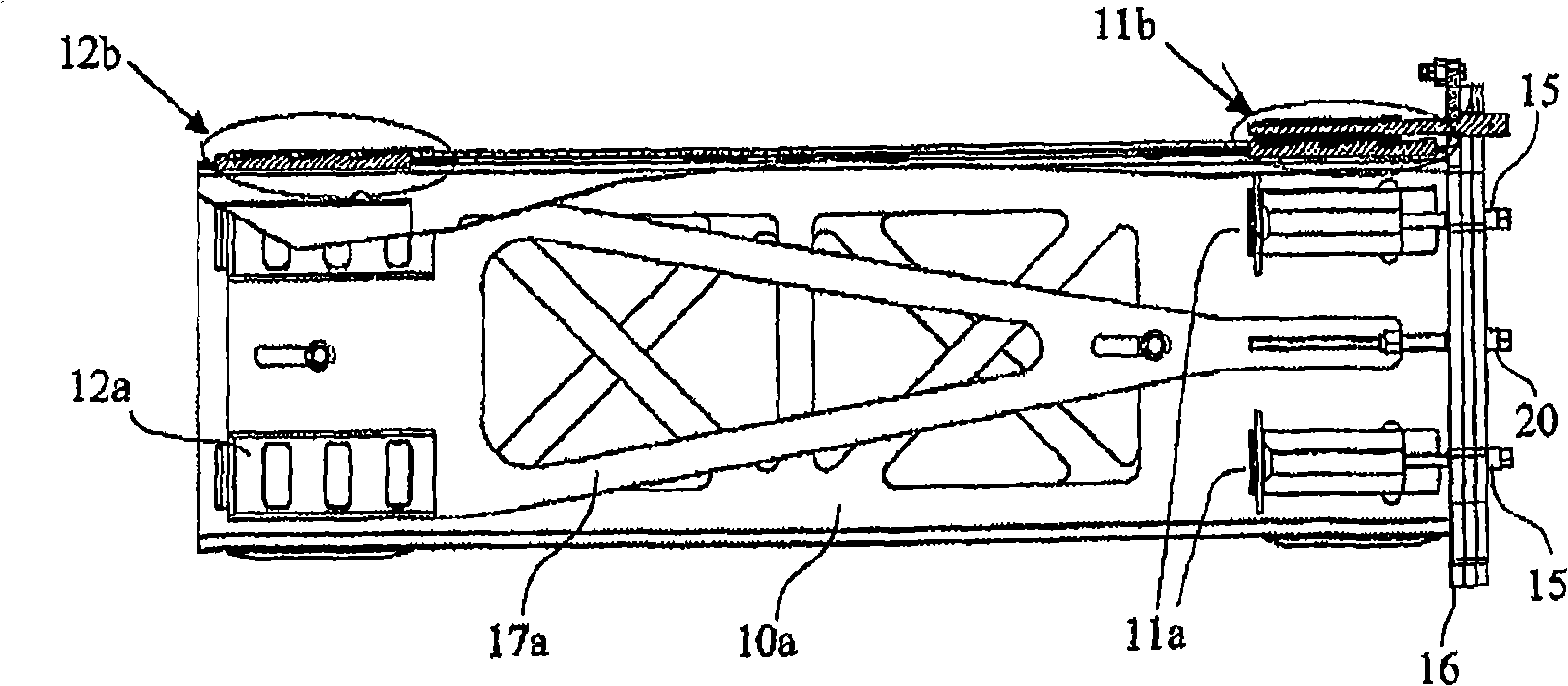

[0028] When manipulating and drilling the rock drilling equipment, the cantilever 1 needs to be extended to position the drilling equipment. For this purpose, the boom 1 is telescopically extendable and is equipped with an outer arm 5 and an inner arm 6 . The outer arm 5 comprises, for example, or consists o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com