Single layer touch control sensing structure and touch control display panel using the same

A touch display panel and touch sensing technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve problems such as screen wear, sensor error judgment, poor light transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

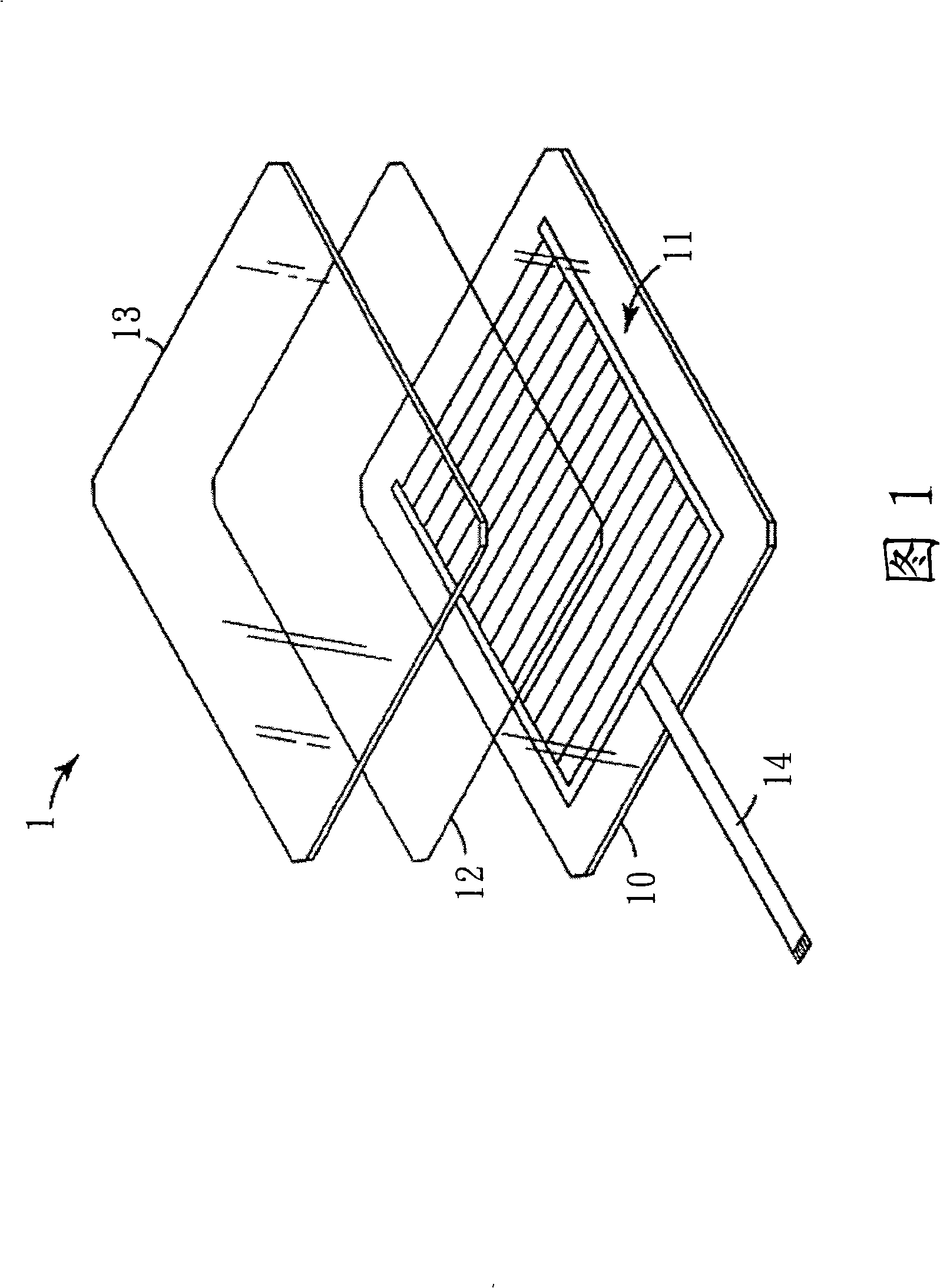

Image

Examples

Embodiment Construction

[0020] In order to have a further cognition and understanding of the features, purposes and functions of the present invention, the relevant detailed structure and design concept of the device of the present invention will be explained below, so that the review committee can understand the characteristics of the present invention, in detail The description states the following:

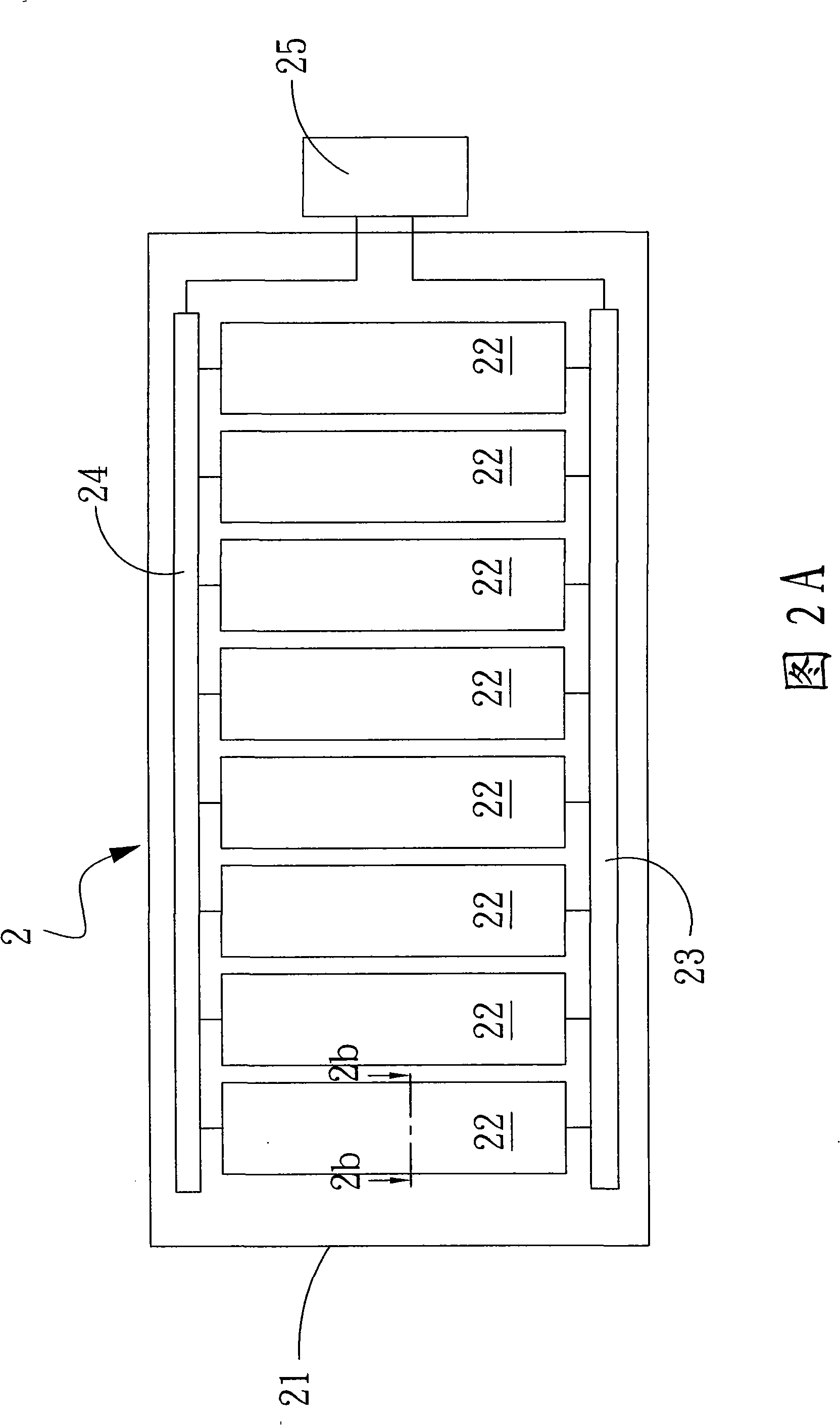

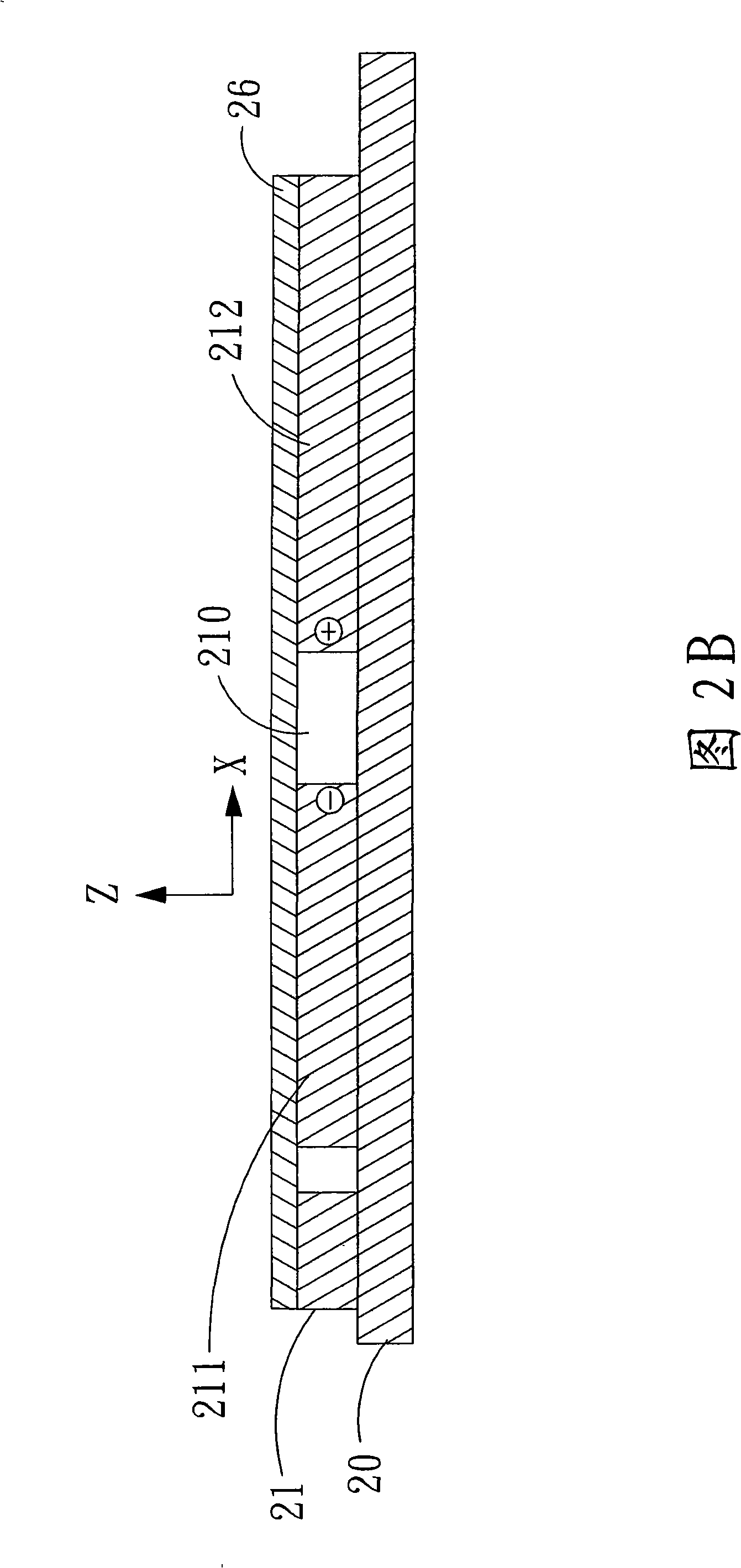

[0021] Please refer to FIG. 2A , which is a schematic diagram of an embodiment of a single-layer touch sensing structure of the present invention. The single-layer touch sensing structure 2 includes a conductive layer 21, which has a plurality of sensing blocks 22, and the sensing blocks 22 have multiple segments of grooves to divide the sensing blocks into A plurality of electrodes, any two adjacent electrodes can form a planar capacitance structure. The single-layer touch sensing structure 2 of the present invention is characterized in that only one conductive layer 21 can be used to complete the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com