Dispersed black dye composition

A technology of dye composition and disperse black, applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of harmful aromatic amines and unsatisfactory blended fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

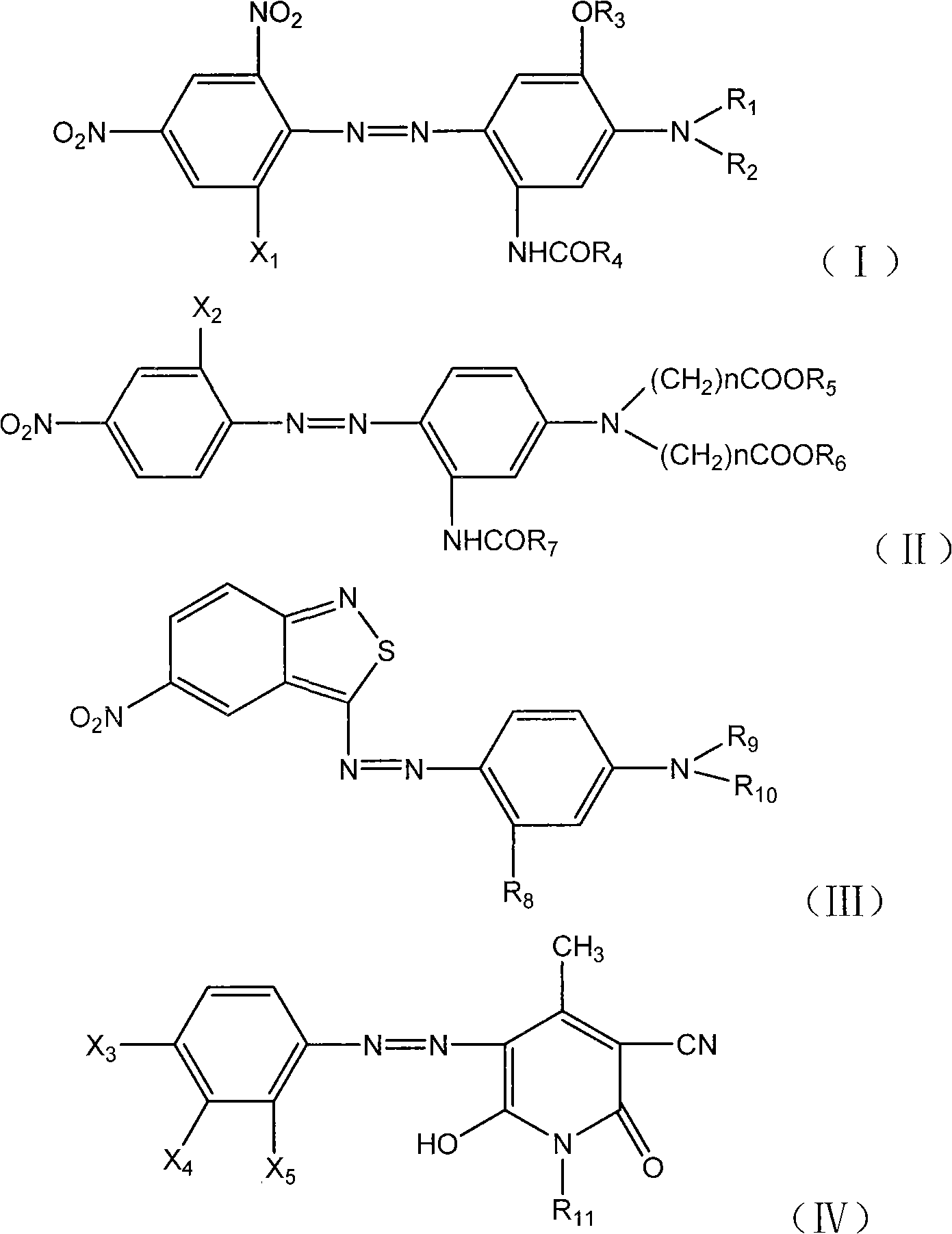

Method used

Image

Examples

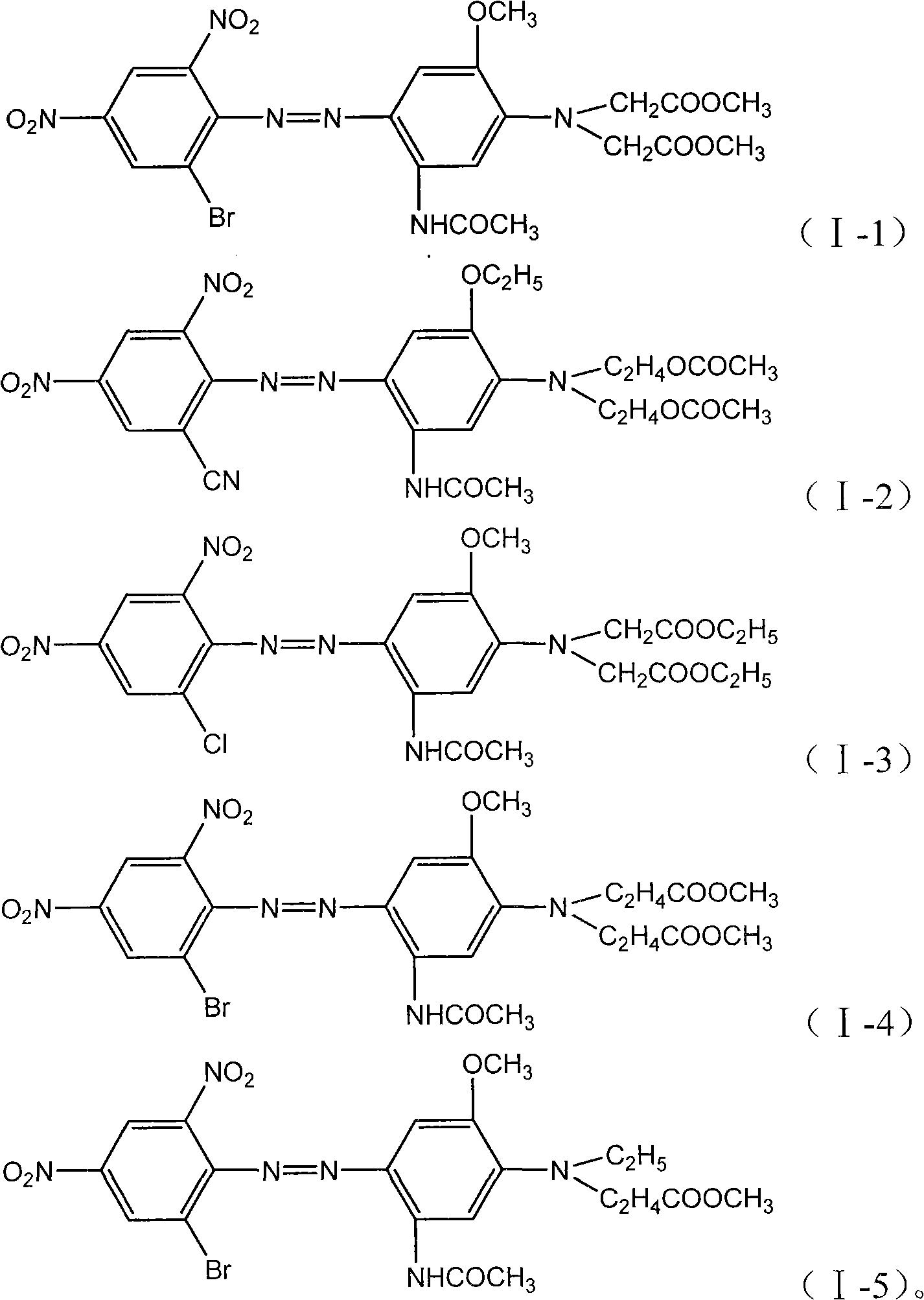

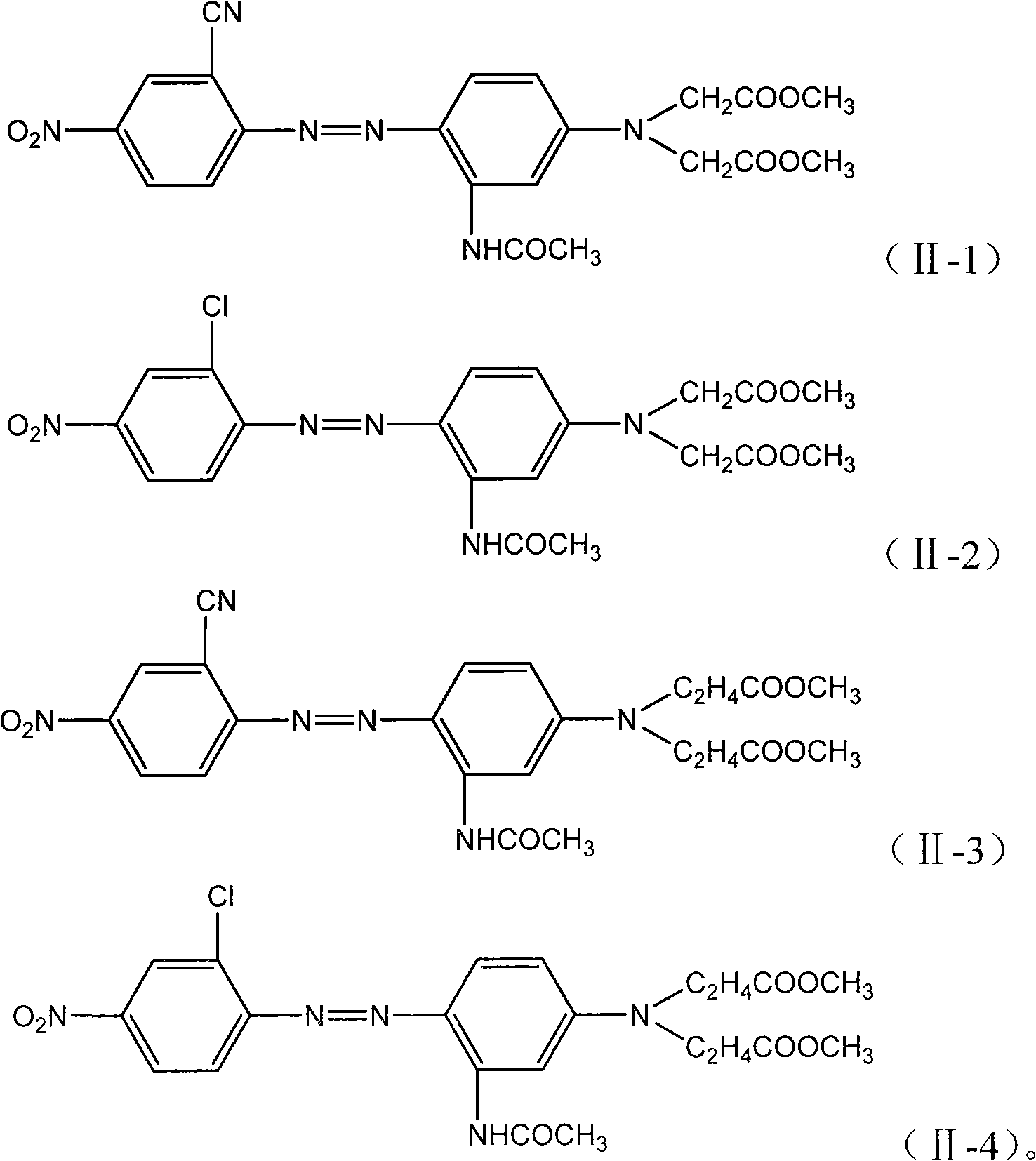

Embodiment 1

[0041] Component A of 60 grams of formula (I-1), component B of 14 grams of formula (II-1), component C of 6 grams of formula (III-1), the group of 20 grams of formula (IV-1) Divide the sodium lignosulfonate of D, 150 grams, after adding water and blending, grind and disperse with grinder, spray dry, obtain finished product, this dyestuff can provide the black that fabric is even and fastness performance is good.

Embodiment 2~17

[0043] According to the data shown in Table 1, after blending component A, component B, component C, component D, additives, and water, use a grinder to grind and disperse, and then spray dry to obtain a finished product, which can be provided to Black color with uniform fabric and good fastness properties.

[0044] Table 1

[0045]

[0046]

Embodiment 18

[0048] Component A of 56 grams of formula (I-1), component B of 14 grams of formula (II-1), component C of 6 grams of formula (III-1), the group of 20 grams of formula (IV-1) Divide D, 4 grams of C.I. Disperse Violet 93, 150 grams of sodium lignosulfonate, add water and blend, grind and disperse with a grinder, and spray dry to get the finished product. This dye can provide fabrics with uniform and good fastness properties. black.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap