Pulverizing apparatus and method

A rotating shaft and breaking technology, which is applied in glass cutting devices, glass manufacturing equipment, grain processing, etc., can solve the problems of broken end materials of liquid crystal panels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

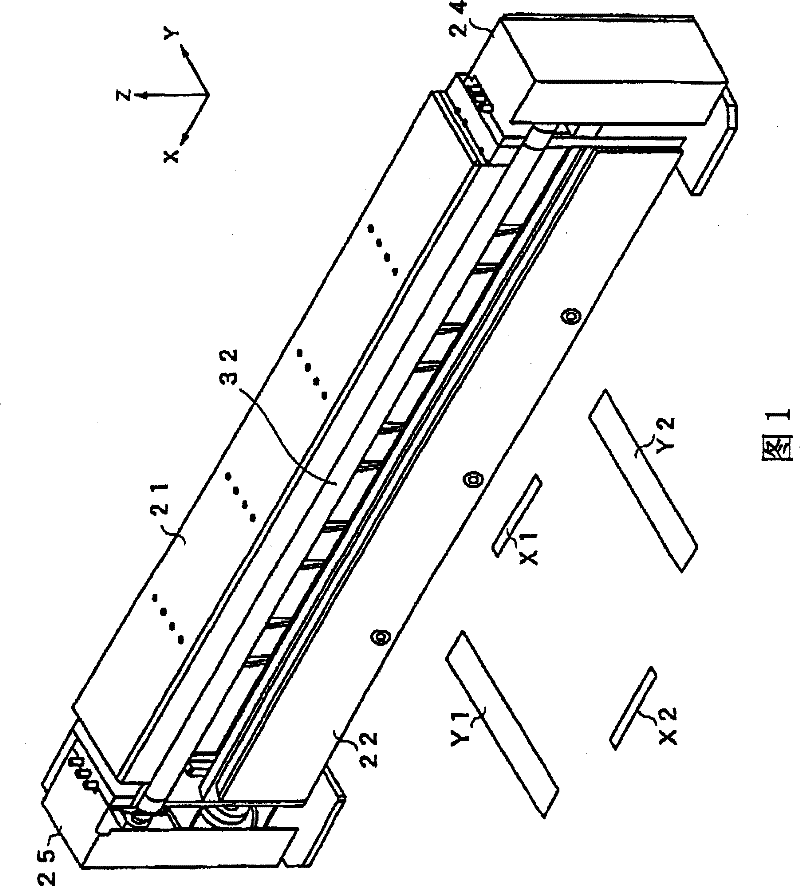

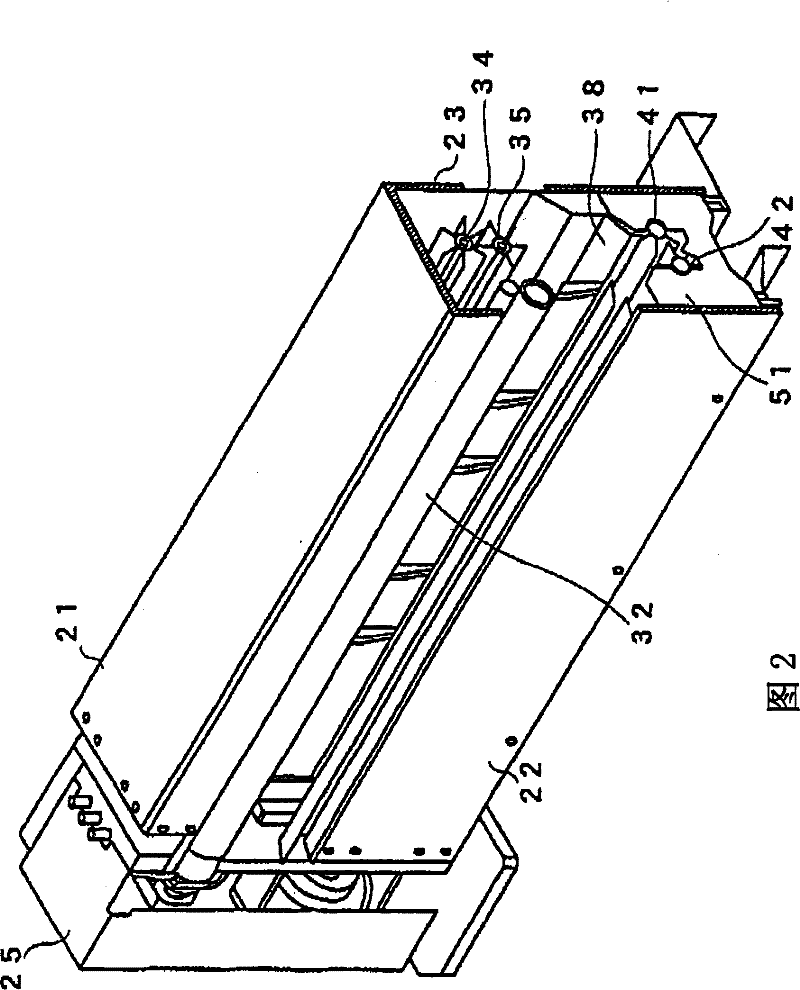

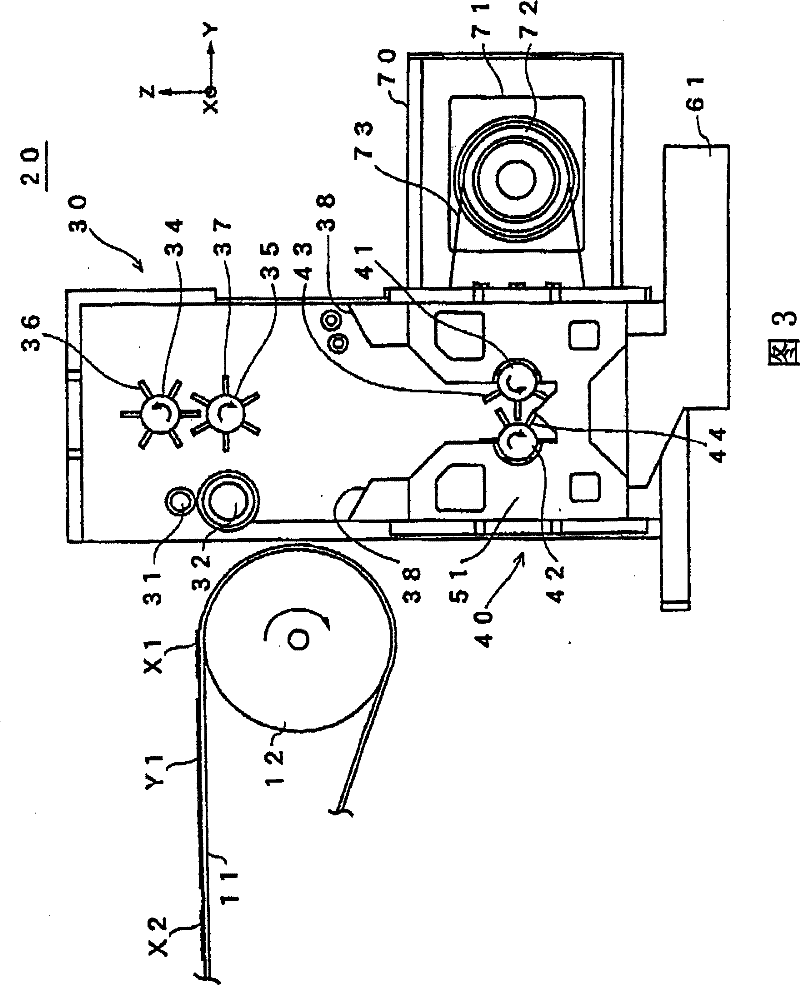

[0038] figure 1 It is a perspective view showing the overall configuration of the crushing device according to the first embodiment of the present invention, figure 2 is a three-dimensional view in vertical longitudinal section along its long side, image 3 A sectional view showing the internal structure. The end material carried into this crushing device is the mother substrate of liquid crystal, which is cut by a glass substrate cutting device (not shown), and then the end material remaining after the single liquid crystal panel substrate is removed. The crushing device of this embodiment is a processing image 3 A crushing device for end materials (hereinafter referred to as Y end materials) Y1 and Y2 in the horizontal direction of the paper surface and end materials (hereinafter referred to as X end materials) X1 and X2 in the direction perpendicular to the paper surface. These X end materials and Y end materials are conveyed by the conveyor belt 11 . The rollers 12 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com