Vegetable dewatering device capable of accurately rotating without gap after repeated pressing

A vegetable dehydration and no-gap technology, which is applied in home appliances, food processing, food science, etc., can solve problems such as obstacles, difficult assembly, and failures, and achieve the effect of easy use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

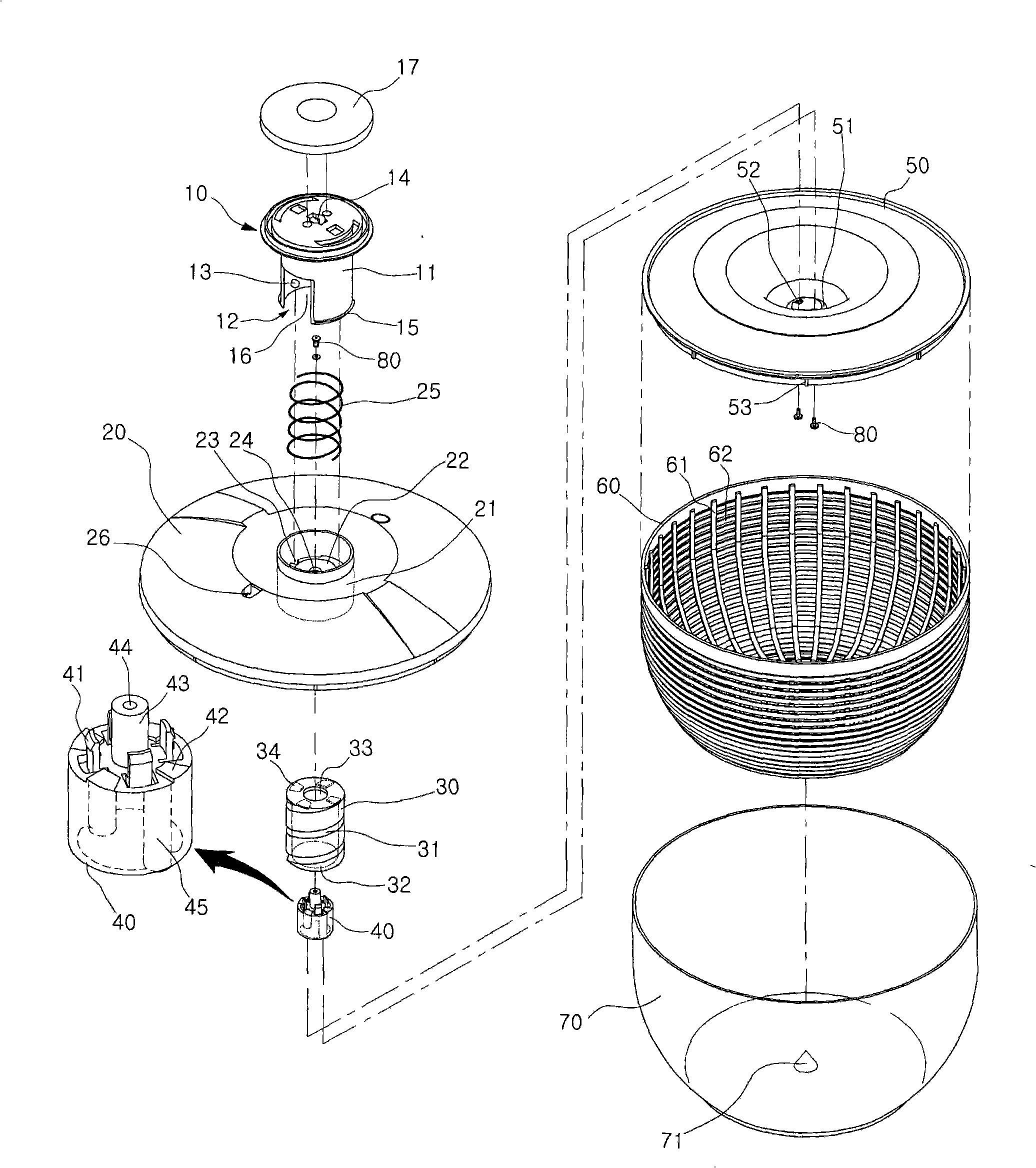

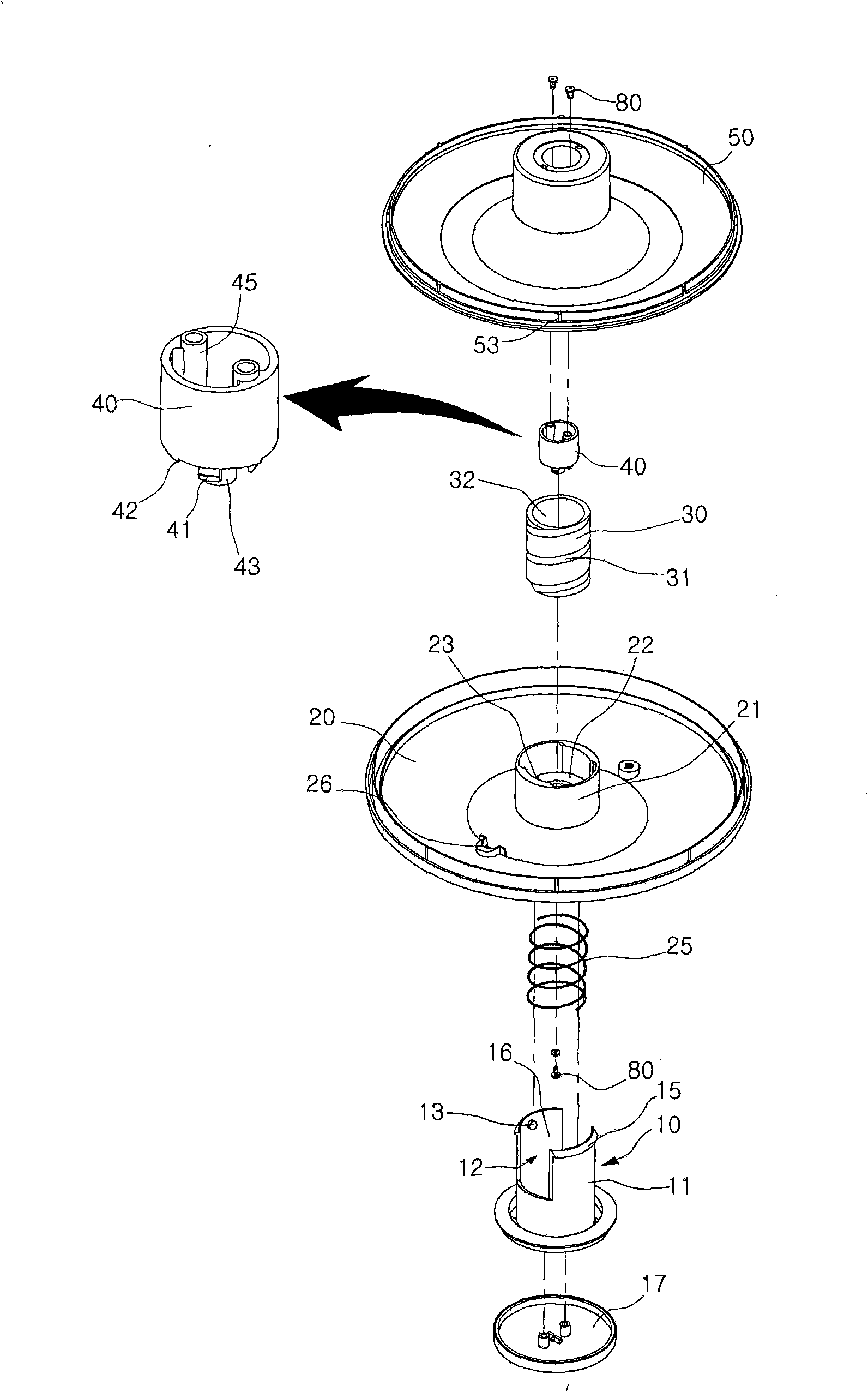

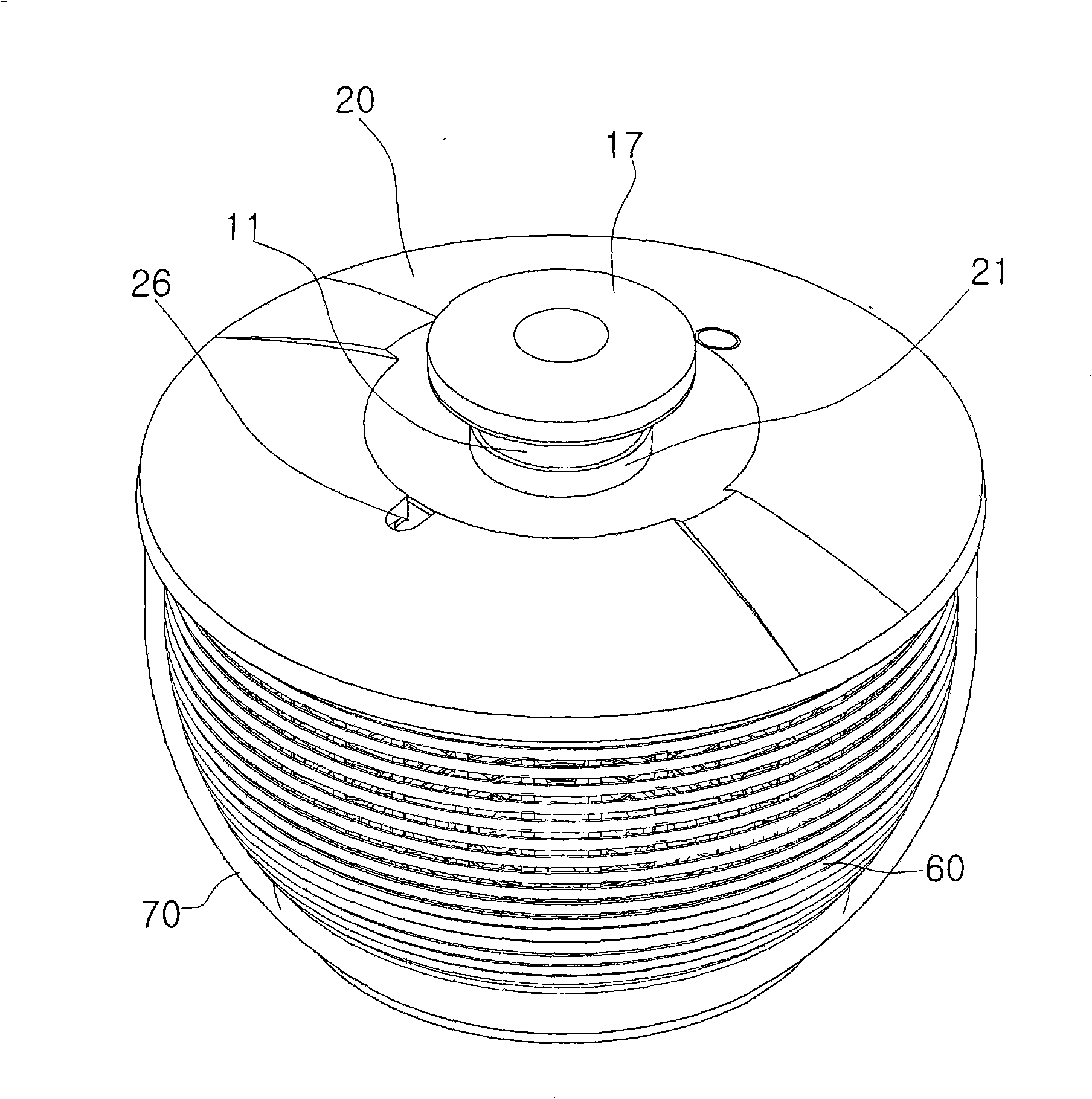

[0040] see Figure 1-8 As shown, as mentioned above, the structure of the vegetable dehydrator of the present invention is provided with on the outer cylinder (70) of the axial protrusion (71) of the specified size and the inner side of the above-mentioned outer cylinder (70) formed by the structure of the vegetable dehydrator of the present invention. The rotary net (60) that rotates, and the rotary plate (50) that is used to convey the rotational force of the above-mentioned rotary net (60), the cover (20) is combined on the upper side of the above-mentioned rotary plate (50), on the top of the above-mentioned cover (20) The central lower end forms a protruding tube (21), the inner side forms a mounting portion (22) for installing a spring (25), the side forms a clamping groove (23), and the center forms a groove (24). The lower end of the groove (14) forms a guide rod (11) of a prescribed length in the inner space (12), and a spring (25) is provided inside it to make the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com