Color-band guide parts and printing device

A technology for guiding components and printing devices, applied in the direction of inking devices, printing, etc., which can solve problems such as ink smearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0032] (structure)

[0033] Figure 4 What is shown is the structure of the ribbon guide part and the printing device. 14 is an ink ribbon cassette, which has an ink ribbon 15 for printing on a printing medium not shown in the figure. The knob 16 is used to wind up the slack ribbon 15 by rotating the knob 16 when the ribbon 15 is slack.

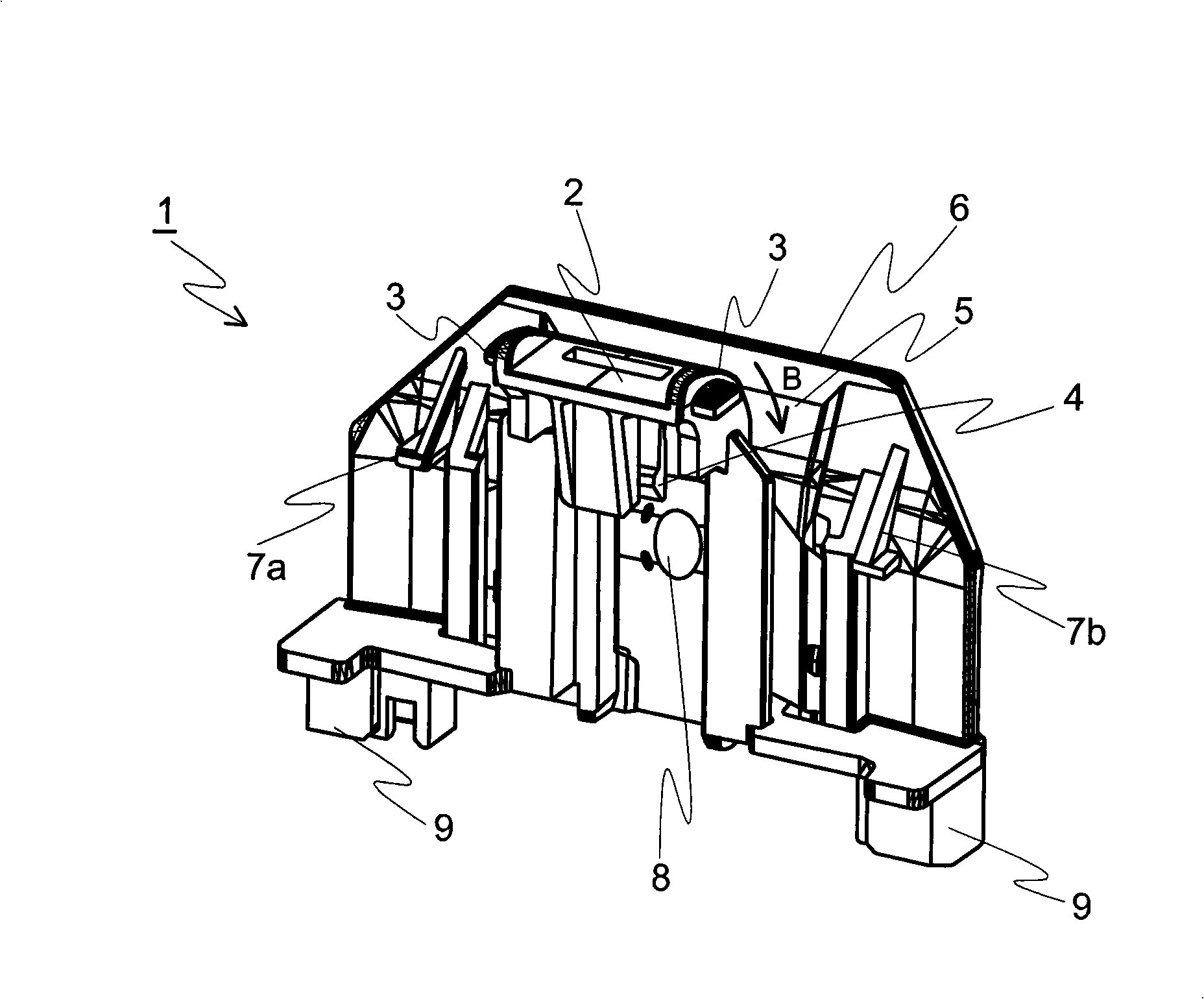

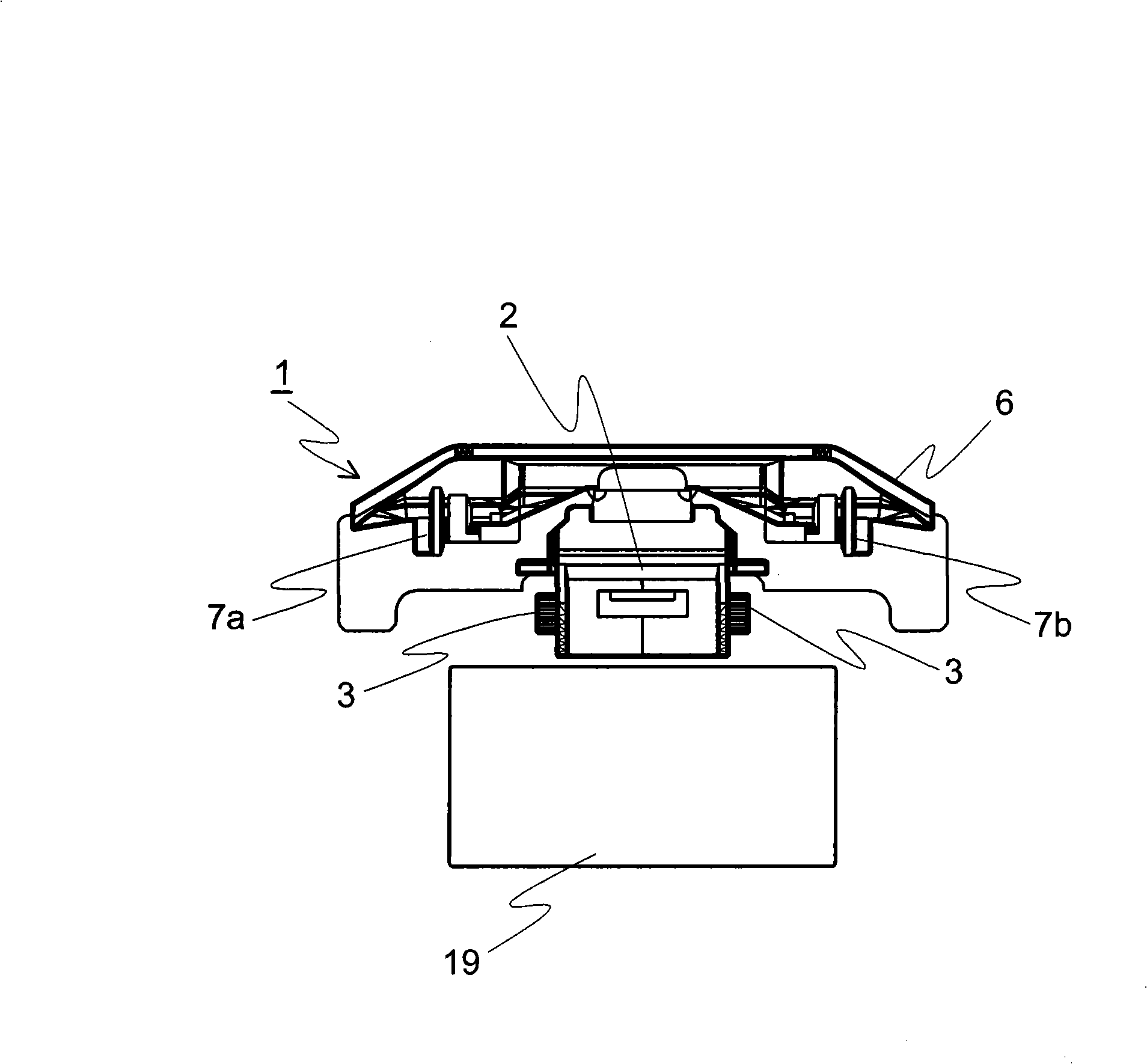

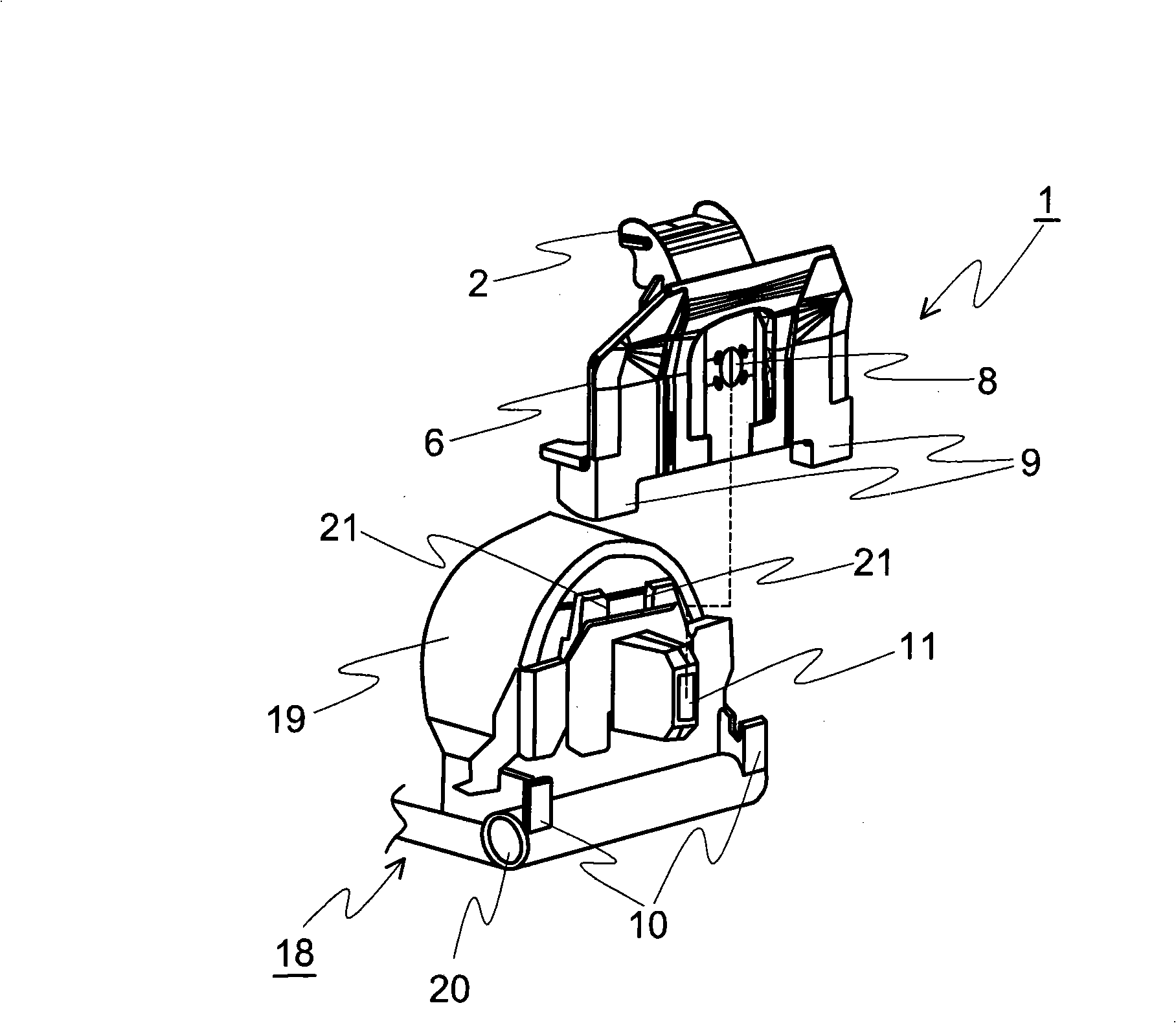

[0034] 1 is a ribbon guide member, which is composed of a guide part 2 and a ribbon protection bracket 6, and is a supporting part that supports the ribbon 15 to move freely. In addition, the ribbon guide member 1 can be detached from the ribbon cassette 14 and the printing device 13 .

[0035] 13 is a printing device, and the printing head 19 writes printing information on the printing medium through the ribbon 15 supported by the ribbon guide member 1 .

[0036] The print head carriage 18 is loaded with the print head 19 and the ribbon protection bracket 6, along the carriage shaft 17 parallel to the platen 12, the spacing is adjusted i...

Embodiment approach 2

[0058] (structure)

[0059] Such as Figure 9 and Figure 10 As shown, in order to minimize the obstruction when the ribbon 15 is installed on the ribbon guide member, the ribbon guide member and the printing device of the second embodiment exclude the ribbon of the ribbon protection bracket 6 in the first embodiment. Guide part 7b. The other configurations are the same as those of the ribbon guide member and the printing device in Embodiment 1, and therefore detailed description thereof will be omitted.

[0060] in addition, Figure 9 and Figure 10 In order to more clearly show the ribbon guide part 7a, the guide part 2 already described in the first embodiment is omitted.

[0061] (action)

[0062] With the above structure, the ribbon guide member and the printing device according to Embodiment 2 can perform the following operations. Use the following Figure 11 The action description diagram in the figure explains this action in detail.

[0063] Figure 11 And in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap