High-energy efficiency low energy consumption large-sized natural circulation boiler with water pipe

A technology of natural circulation and water tube boilers, applied in water heaters, lighting and heating equipment, fluid heaters, etc., to achieve low energy consumption, low emissions, and reduced steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

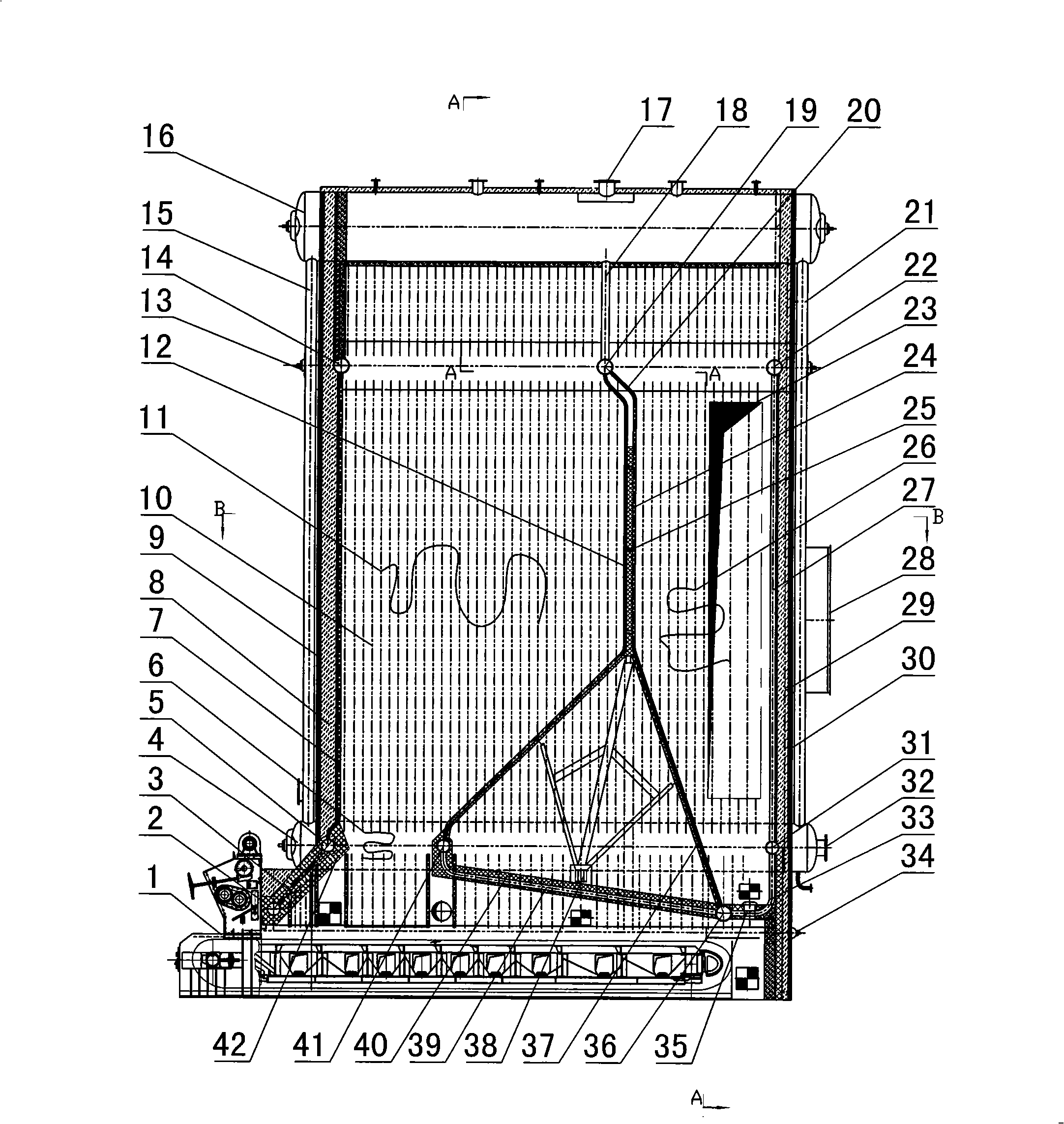

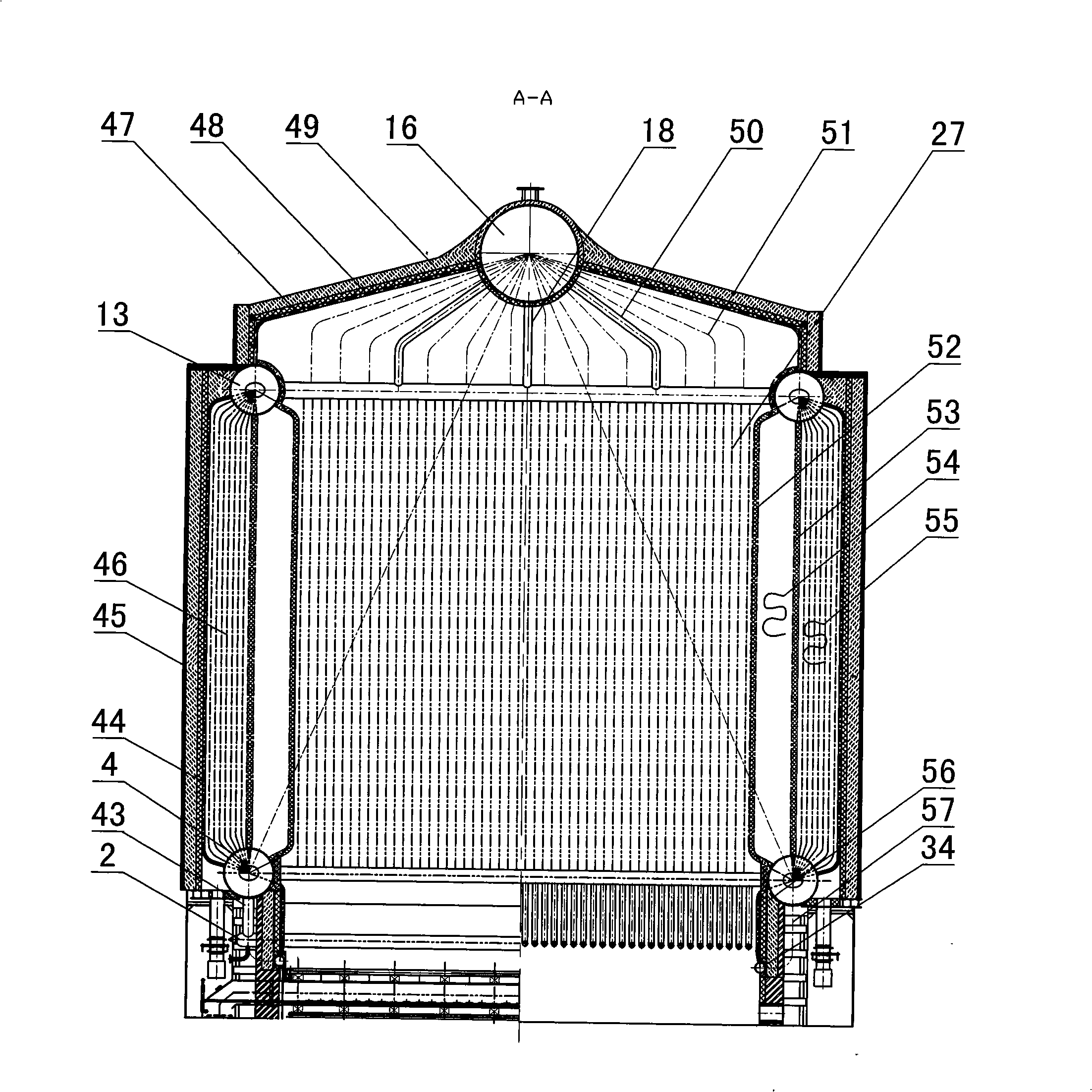

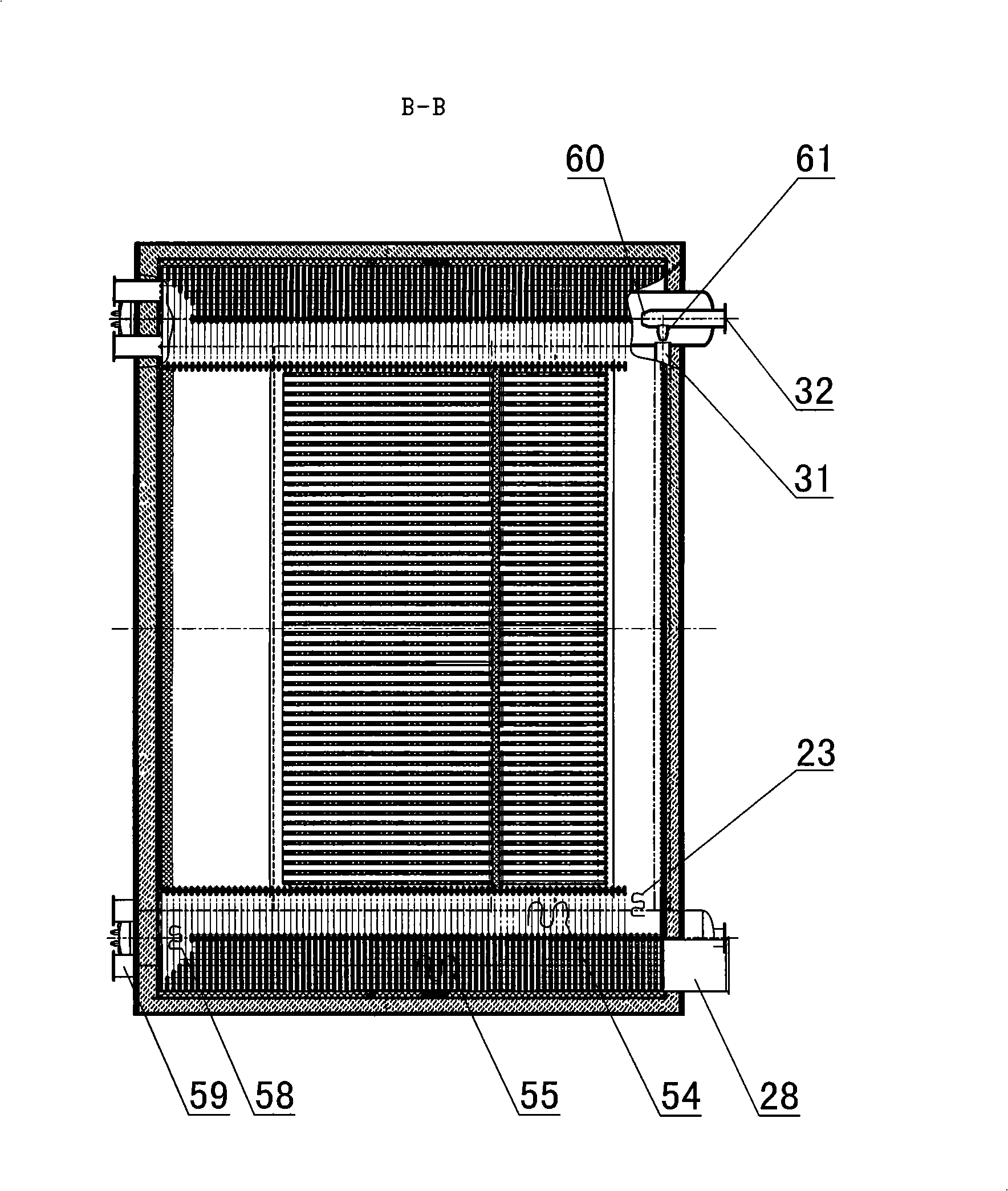

[0012] Below in conjunction with accompanying drawing, the present invention is described in detail

[0013] A large-scale natural circulation water tube boiler with high energy efficiency and low energy consumption, which consists of a drum (16), downcomer (21), side upper and lower headers (13), (4), support and hanger (38), ejector tube ( 60), (61), characterized in that the upper end of the roof pipe (47) communicates radially with the longitudinal center of both sides of the drum (16), and its lower end is longitudinally connected with the top center of the side upper header (13) Evenly distributed and connected; the upper end of the water-cooled wall tube (10) communicates radially with the inner center of the upper side header (13) and radially communicates with the inner center of the lower side header (4) and radially communicates with the inner center of the lower side header (4); the convection tube bundle The upper end of (46) communicates with the lateral center o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap