A method for denitration of coke oven flue gas

A coke oven and flue gas technology, applied in the field of air pollutant control, can solve the problems of low denitrification efficiency, achieve the effects of reducing emissions, reducing original emission concentrations, and simplifying equipment layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below by embodiment, can understand the present invention better. However, those skilled in the art can easily understand that the content described in the embodiments is only for illustrating the present invention, and should not and will not limit the present invention described in the claims.

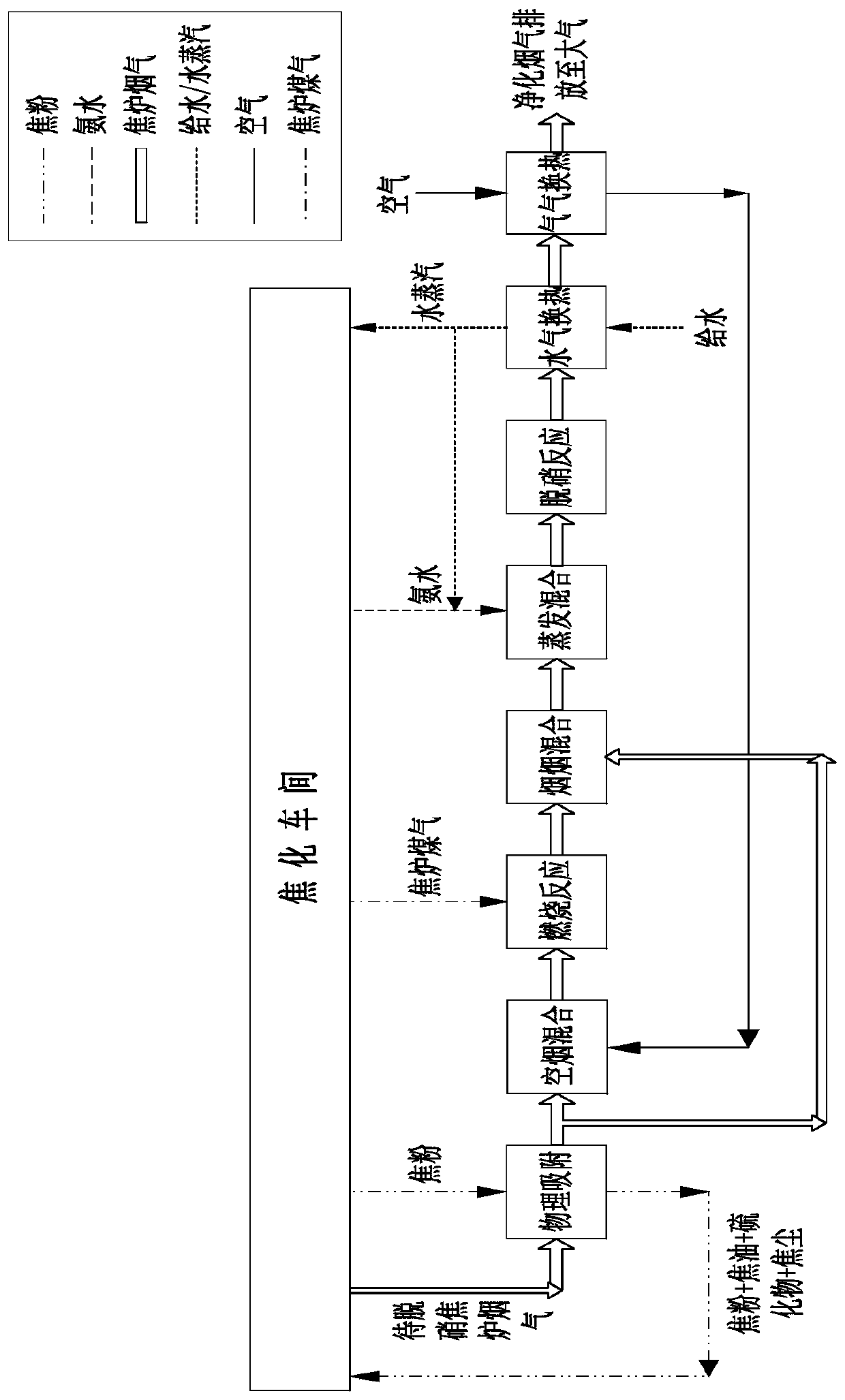

[0033] This example is aimed at 2×65 hole coke ovens, and the flue gas production of a single coke oven is 150000Nm 3 / h, flue gas temperature 260°C, original emission concentration of nitrogen oxides 1000mg / Nm 3 . The denitrification process steps are as follows (such as figure 1 shown):

[0034] (1) Put the coke powder with a particle size range of 0.5-10mm in the coking workshop in a cross-flow bed, and at the same time pass the coke oven flue gas with a temperature of about 260 °C through the bed, most of the tar, some sulfides and coke dust Physically adsorbed by the coke powder, the adsorbed coke powder returns to the coking workshop as a takeaway product, while the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com