Semi-mounted back-turning self-discharging vehicle underpan

A chassis and frame technology, applied in the field of dump truck chassis structure, can solve problems such as impact, poor vehicle performance, and impact on loading and unloading, and achieve the effects of reducing overall height, low center of mass, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

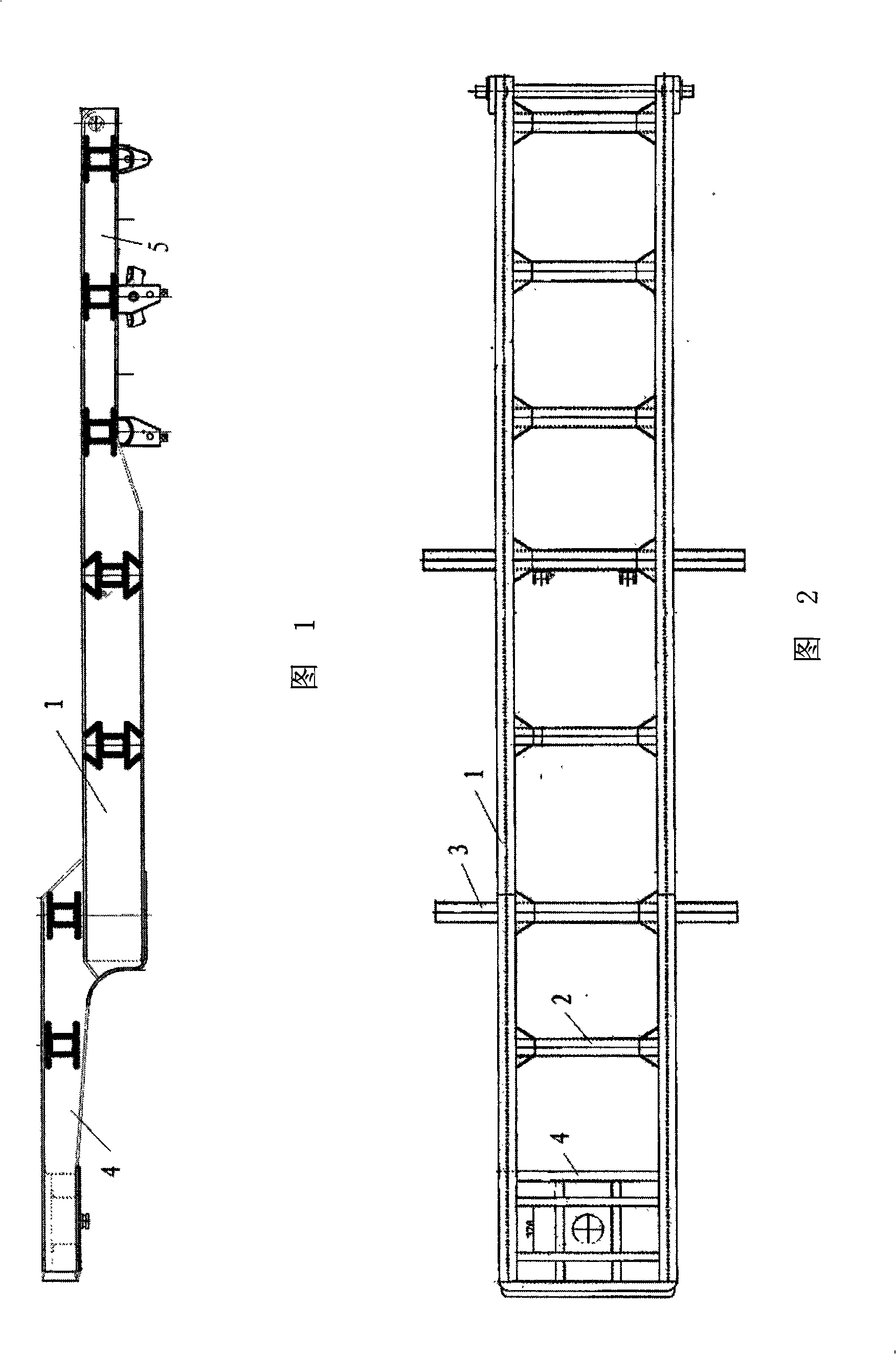

[0011] Referring to Figures 1 and 2, the chassis of a semi-trailer rear-turning dump truck in this embodiment changes the traditional design routine, and the existing straight structure of the frame longitudinal beam is a gooseneck structure, and the front end of the frame longitudinal beam 1 An arched front part 4 is provided, which is called a gooseneck, and a recessed rear part 5 is provided at the rear end of the vehicle frame longitudinal beam 1, and the thickness of the rear part 5 is smaller than the thickness of the middle part of the vehicle frame longitudinal beam 1, so that Lower the load-bearing center of gravity of the cargo; chassis longitudinal beam 1 and cross beam 2 can use 22 # and 28 # Made of channel steel, the crossbeam 2 extends outwards to form four supporting contact extension beams 3 that are joined to the bottom surface of the carriage. The extension beams 3 constitute a stabilizing device to ensure the organic and stable combination of the carriage b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com