After-assembly method of aluminum alloy door and window

A post-installation technology for aluminum alloy doors and windows, applied to windows/doors, building components, buildings, etc., can solve problems such as insufficient compactness around door and window frames, pollution of window frames, leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A method for retrofitting aluminum alloy doors and windows, comprising the following steps:

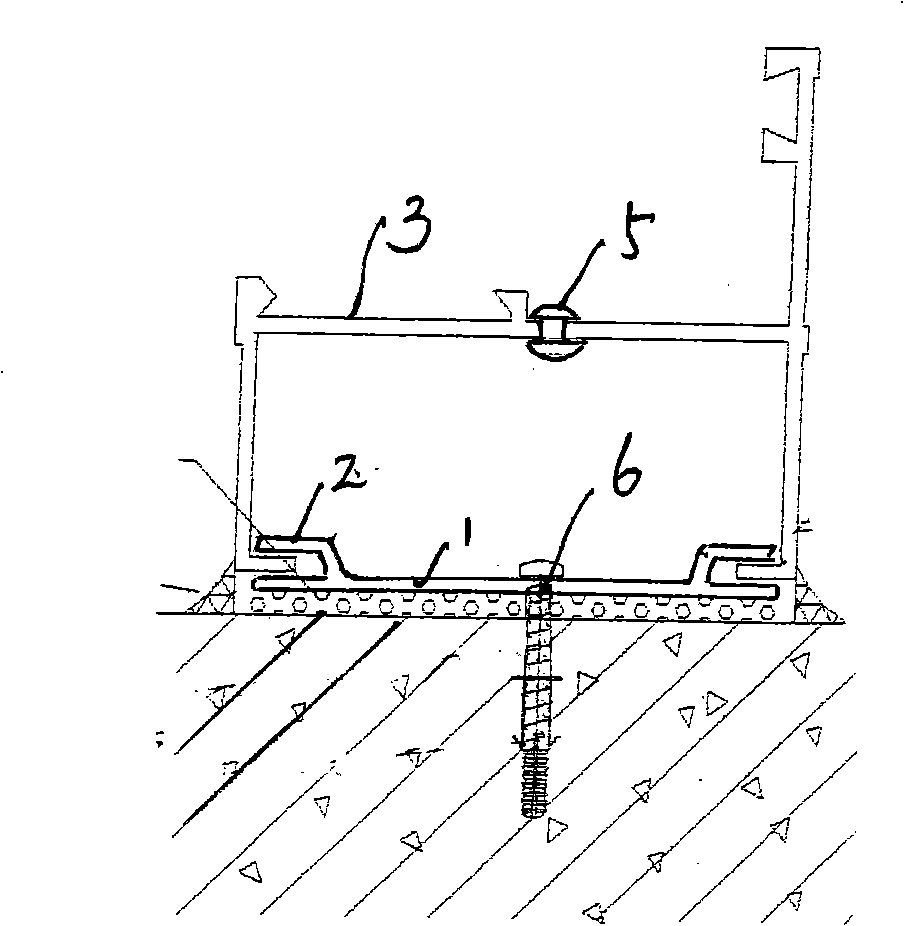

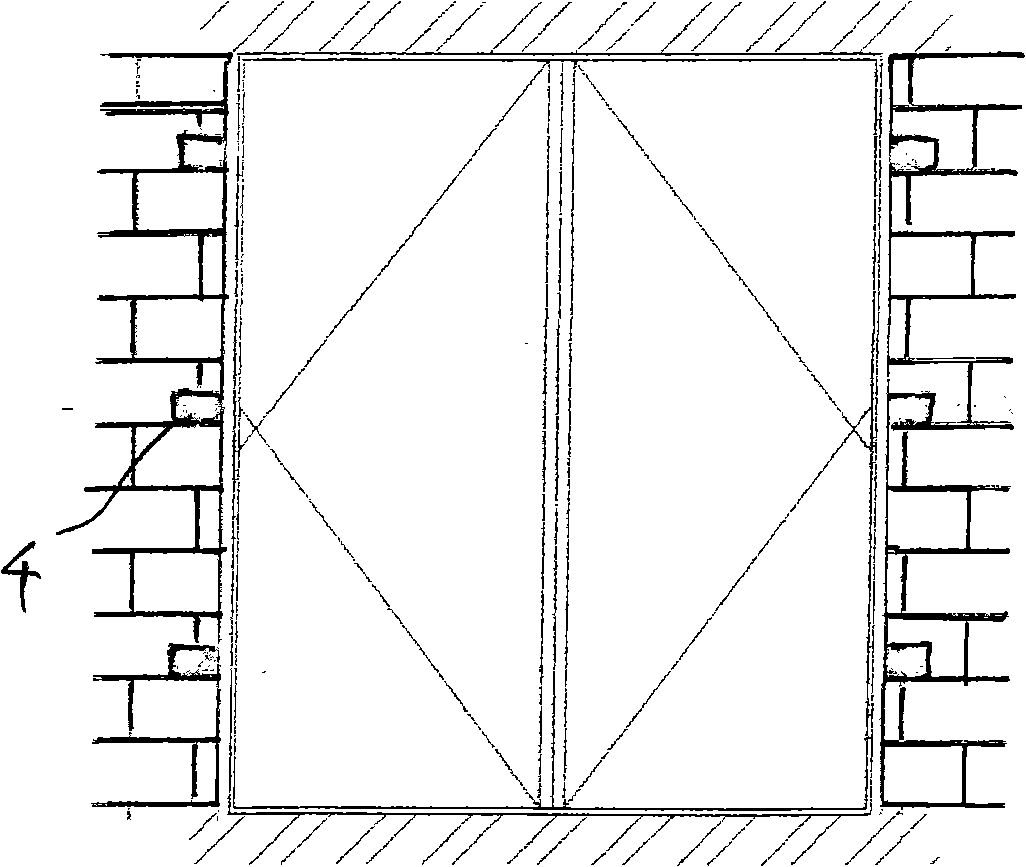

[0019] (1) Paint the reserved openings of doors and windows together with the wall, and mark the concrete block 4 where the door and window frame 3 is fixed;

[0020] (2) Put the aluminum alloy door and window frame into the door and window opening;

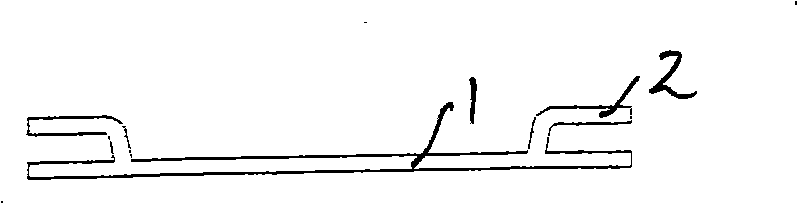

[0021] (3) Slide and engage the fixed metal part with the aluminum alloy door and window frame, and move the fixed metal part to the concrete block described in step (1), and punch a process hole at the corresponding position of the aluminum alloy door and window frame, through the process Use nylon expansion tube 6 to fix the fixed metal parts and concrete blocks in the hole, and then use the process cover 5 to block the process hole;

[0022] (4) Apply foaming agent by needle injection to make the foaming agent dense and uniform in the concave cavity of the aluminum alloy frame, and then apply sealant on the edge of the outer f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com