Sewage inspection well structure performing desilting without stopping water and construction method of sewage inspection well structure

A technology for inspection wells and sewage, which is applied to drainage structures, waterway systems, water supply devices, etc., can solve the problems of difficult desilting and low desilting efficiency in sewage inspection wells, and achieves promising development and application prospects, and desilting is safe, fast and convenient. The effect of subsequent replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

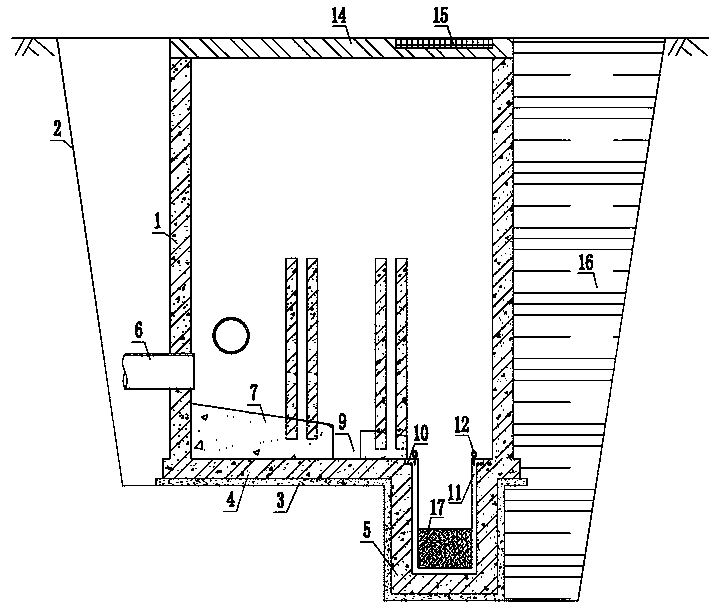

[0051] The present invention will be described in detail below in combination with specific embodiments.

[0052] The sewage inspection well structure and its construction method provided by the present invention, with its innovative structural design and safe and fast dredging process, successfully realize the desilting of the sewage inspection well under the condition of non-stop water The work has effectively solved the current problems of difficult dredging and low dredging efficiency of sewage inspection wells, reduced operation and maintenance costs, and favorably guaranteed the healthy and efficient operation and service life of urban sewage pipes, and sewage inspection wells can be built on site , can also be prefabricated and processed, and the market promotion prospect is bright. At present, there is no relevant report on the structure and construction method of the sewage inspection well for non-stop desilting in China.

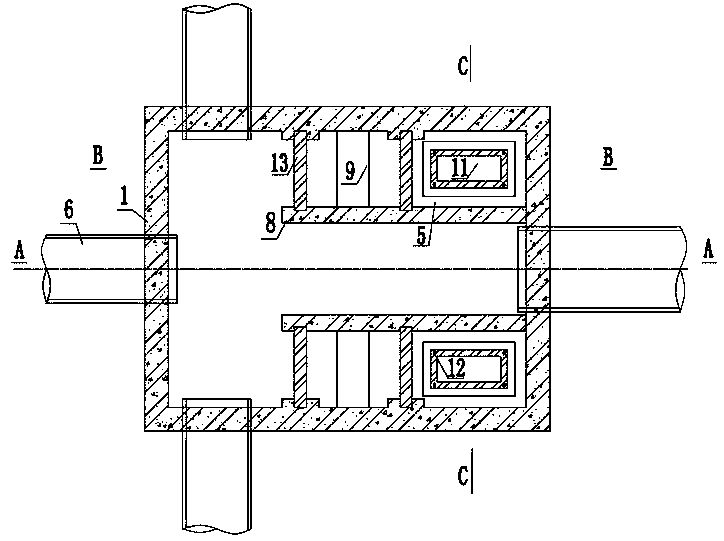

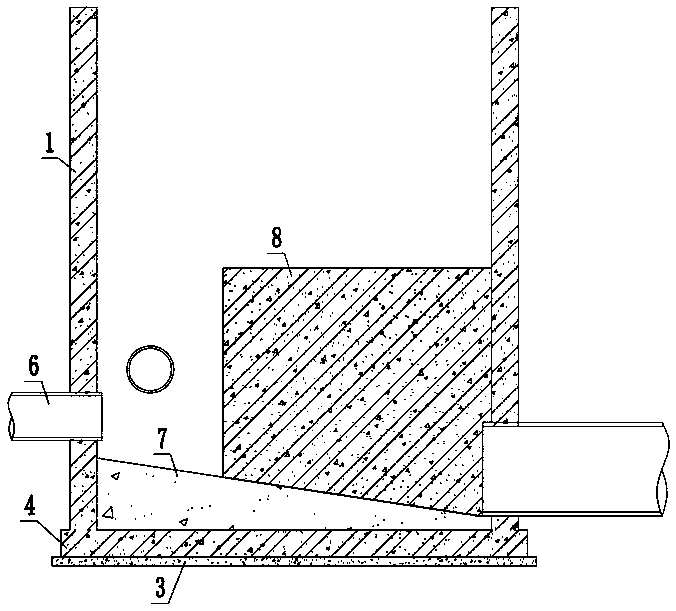

[0053] The sewage inspection well structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com