Microwave measurement system for breeze concentration of power station boiler

A power station boiler and microwave measurement technology, applied in the field of multiphase flow measurement, can solve the problems of increasing measurement error, impossibility of completely purging coal powder, microwave measurement influence, etc., to achieve improved accuracy, simple structure, and increased absorption The effect of attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

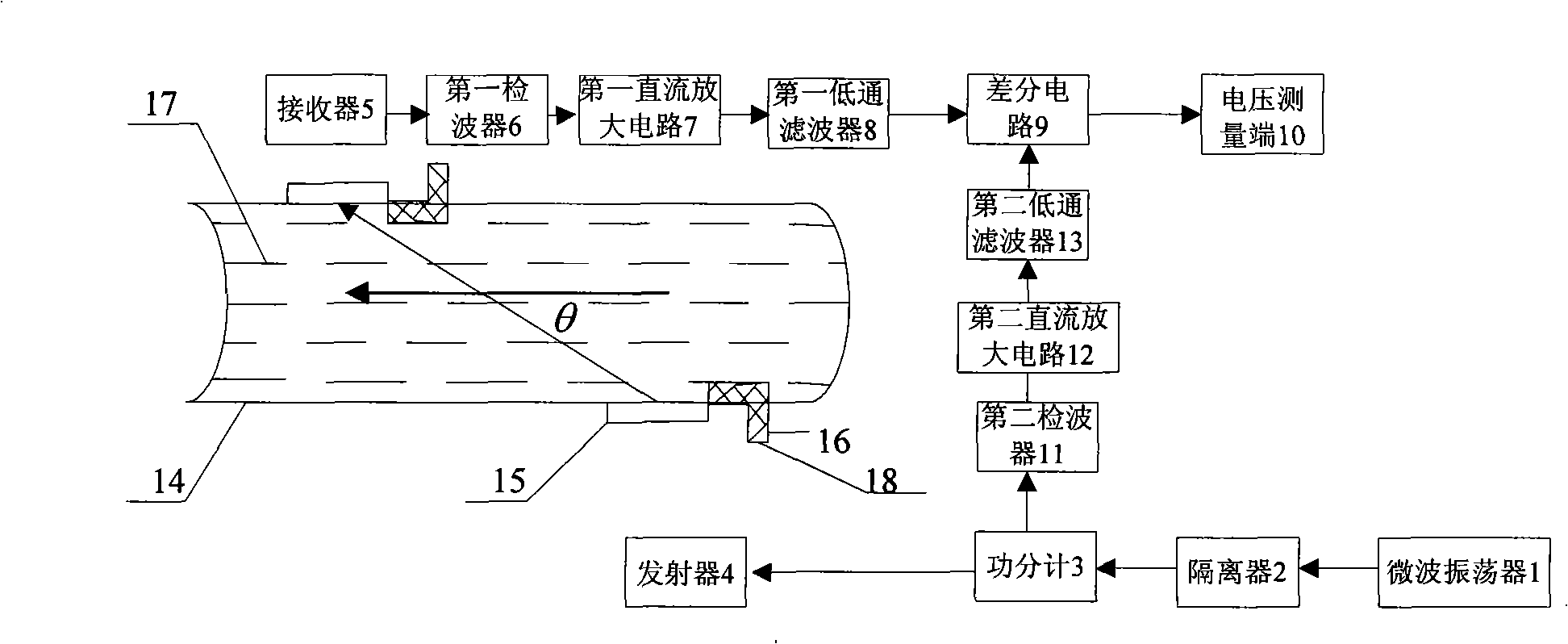

[0021] combine figure 1 , the microwave measurement system of power plant boiler pulverized coal concentration of the present invention, comprises coal conveying pipe 14, transmitter 4 and receiver 5 are arranged on the two sides of coal conveying pipe 14, and install along the radial dislocation so that the microwave signal emitted by transmitter 4 The transmission direction forms an angle θ with the flow direction of the pulverized coal 17 in the coal delivery pipe 14, and the angle θ is most preferably 30°-60°. The transmitter 4 and the receiver 5 can be probes or horn antennas, if the transmitter 4 and the receiver 5 are probes, they are arranged on the inside of the coal delivery pipe 14, and if the transmitter 4 and the receiver 5 are horn antennas, they are arranged on the coal delivery pipe. outside of the tube 14. When the transmitter 4 and the receiver 5 are horn antennas, in order to eliminate the absorption of the microwave signal by the pipe wall, the transmitter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com