Method for manufacturing a double tube discharge lamp

A discharge lamp and inner tube technology, which is applied in the field of manufacturing discharge, can solve problems such as damage to the sealing part, and achieve the effect of eliminating the risk of rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

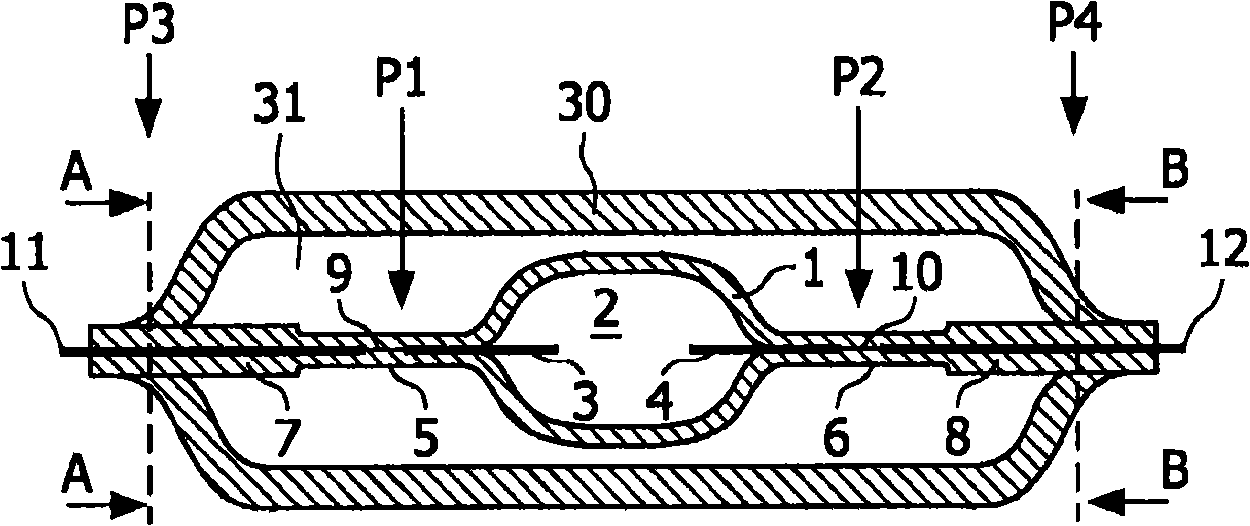

[0023] figure 1 schematically shows a longitudinal section through the main part of a twin-tube discharge lamp comprising a first inner tube 1 and a second outer tube 30 closing the first inner tube 1.

[0024] The first inner tube 1 encloses a discharge chamber 2 which contains a discharge gas. A gas discharge arc is excited between opposite ends of the first electrode 3 and the second electrode 4, which extend into the discharge chamber.

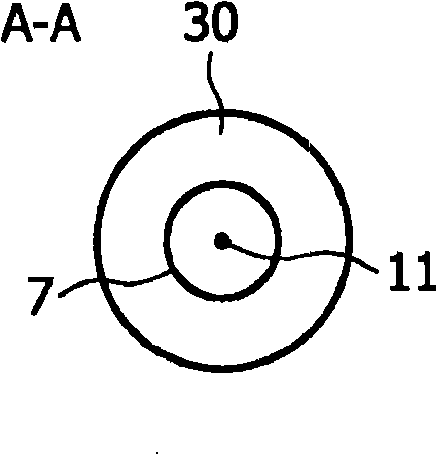

[0025] The second outer tube 30 hermetically closes an inner volume 31 which is preferably filled with gas or dry air or which is evacuated. Furthermore, the second outer tube 30 also closes the first inner tube 1 , the first axial seal 5 and the second axial seal 6 of the first inner tube 1 as well as the first axial extension 7 and the second axial extension. Each of the first axially extending portion 7 and the second axially extending portion 8 passes the first axially sealing portion 5 and the second axially sealing portion 6 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com