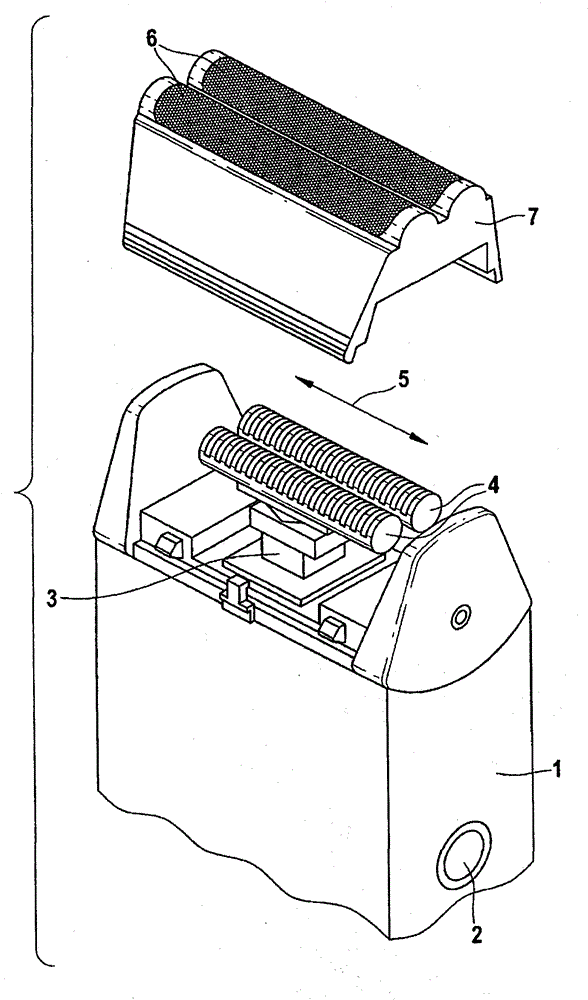

Lower cutter for shaving heads for dry razors

A lower cutter and cutter technology, applied in metal processing and other directions, can solve problems such as damage to perforated metal sheets, uneven distribution of mechanical stress, loss of direct contact, etc., and achieve the effect of ensuring permanence and eliminating notch effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

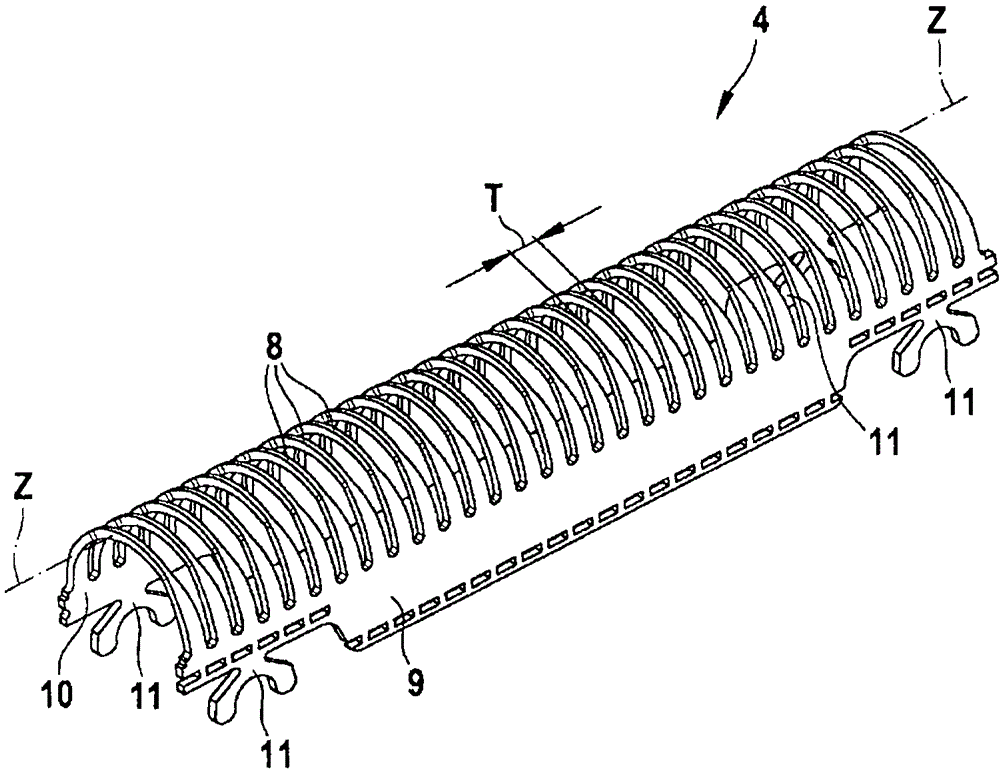

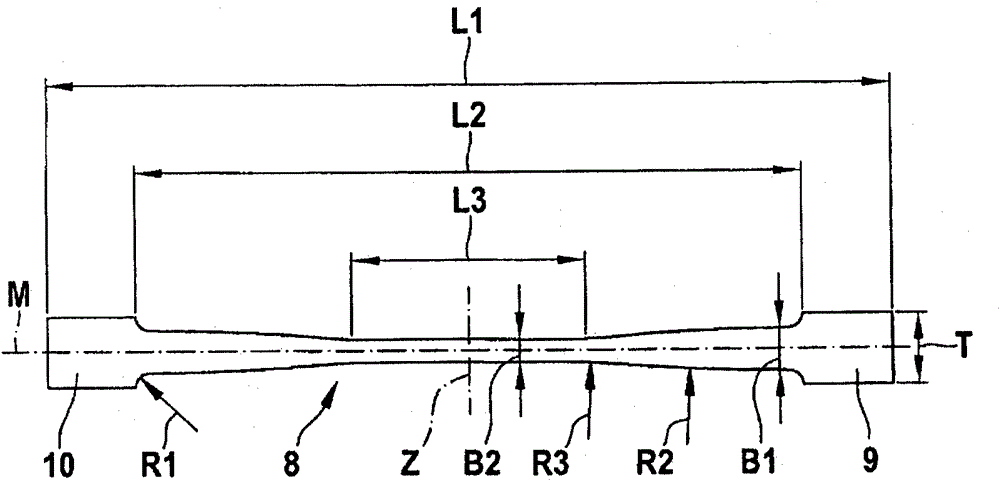

[0021] figure 2 The shown lower cutter 4 according to the invention has a plurality of U-shaped blades 8 extending parallel to each other, which extend in the form of strips between two peripheral regions 10 and 9 . These two peripheral areas 9 and 10 each have a mounting portion 11 at their front and rear ends for connection to a support member, details of which are not shown in the figures, which ultimately serve to connect the lower cutter 4 to the dry razor Action on drive element 3. The longitudinal extent of each peripheral region 9 and 10 between its two mounting parts 11 corresponds to the direction of vibration according to the double arrow 5 . According to the exemplary embodiment shown here, the blade 8 extends perpendicularly to the longitudinal extent of the peripheral regions 9 , 10 . The width of the blades 8 and the distance between the blades of the lower cutter 4 are measured parallel to the longitudinal extent of the peripheral area.

[0022] as in fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com