Cold box molding core maker

A core making machine and cold core box technology, which is applied in the directions of molding machines, casting molding equipment, casting molds, etc., can solve the problems of difficulty in precise positioning, inability to increase, and no large space for core removal by the coring car, and achieves high efficiency. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

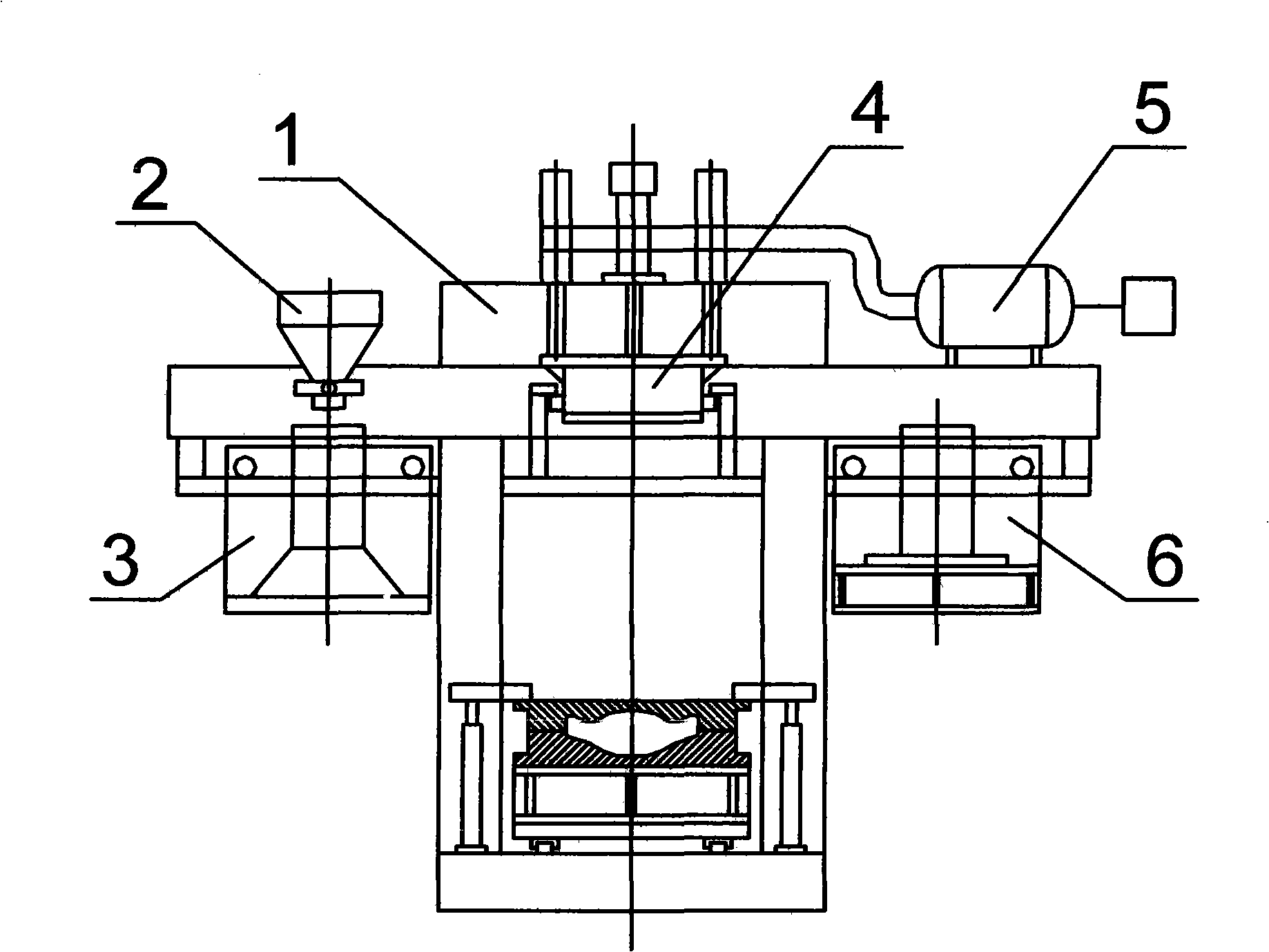

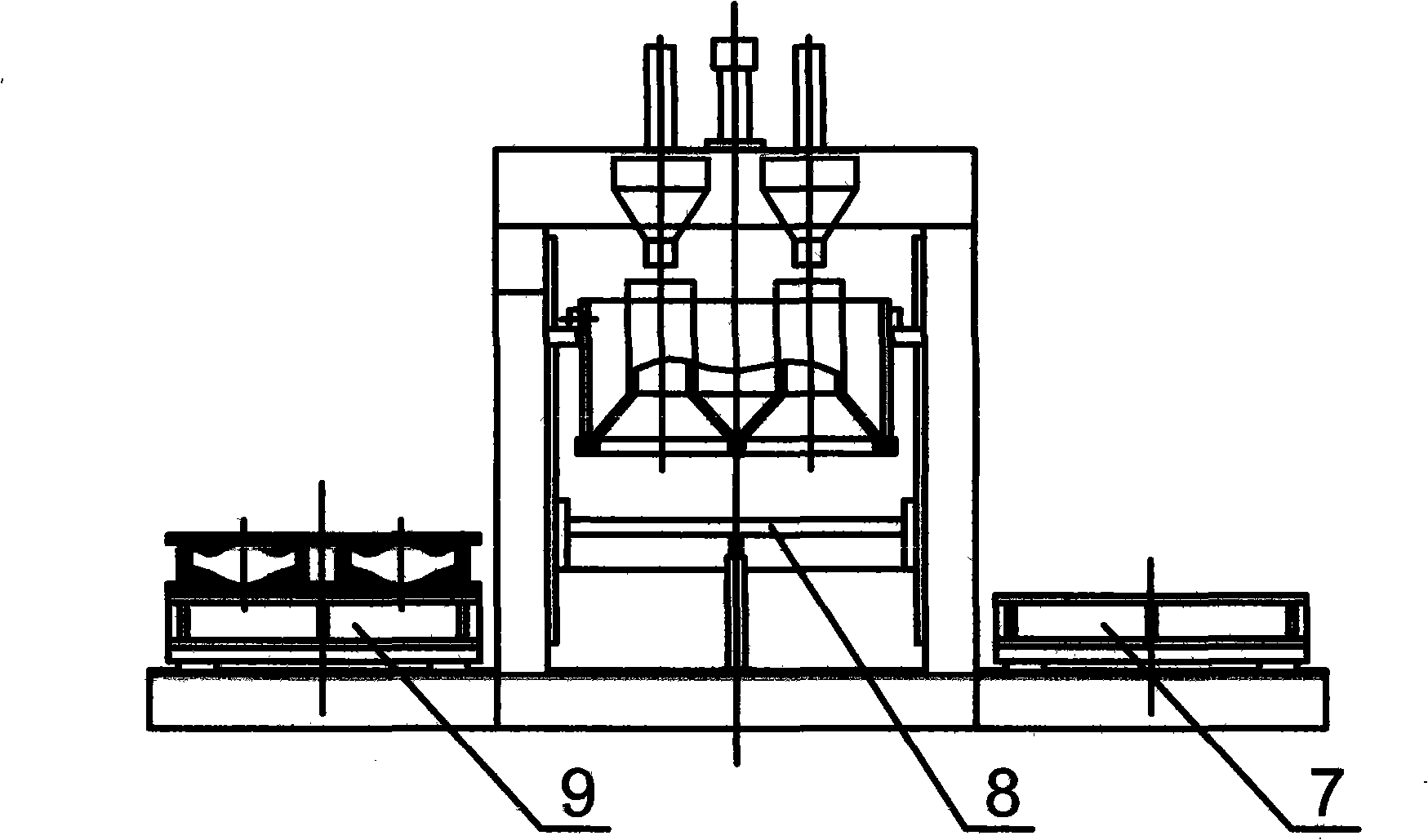

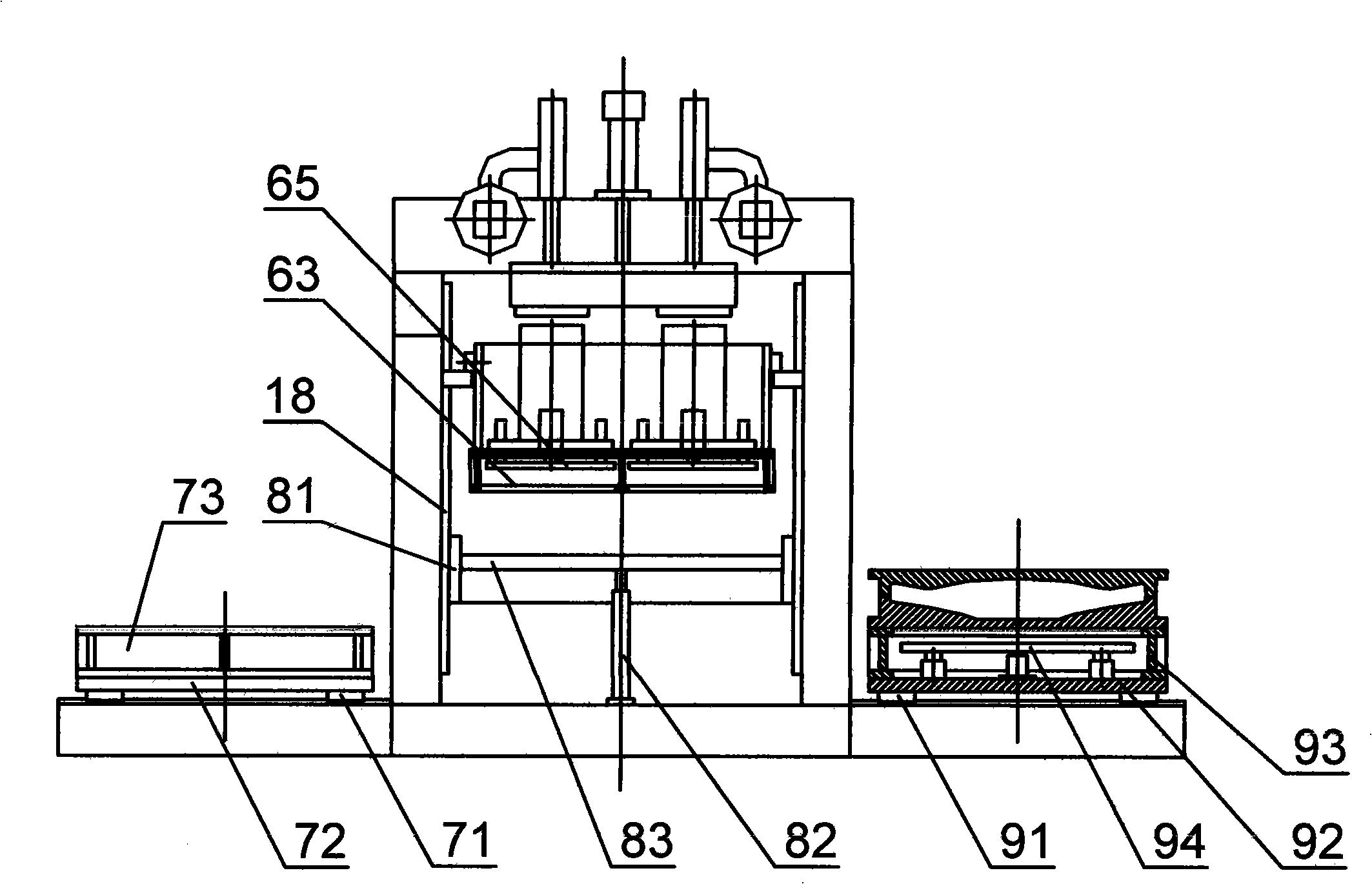

[0024] The basic structure and working principle of the cold box molding core making machine will be described in detail below in conjunction with the attached drawings:

[0025] Basic structure of cold box molding core making machine: see Figure 1 to Figure 5 .

[0026] Cold box molding core making machine includes: frame part 1, sand adding device 2, mobile injection head 3, upper pressure head and sand injection mechanism 4, air bag and pipeline connection 5, mobile air blowing with top core function Cover 6, pallet trolley 7, upper core box lifting mechanism 8 and core box trolley 9 with lower top core function. Frame part 1 comprises upper frame 11, crossbeam 12, column 13, base 14, and is made up of rigid frame by above-mentioned parts; Above, the vertical linear guide rail 18 is fixed on the inner side of the column 13, the movable guide rail 17 and the upper core box lifting mechanism 8 slide up and down along the vertical linear guide rail 18; the horizontal linear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com