Positioning ring

A positioning ring and fixing plate technology, which is applied in the field of positioning rings, can solve the problems of inconvenient storage and storage of positioning rings, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

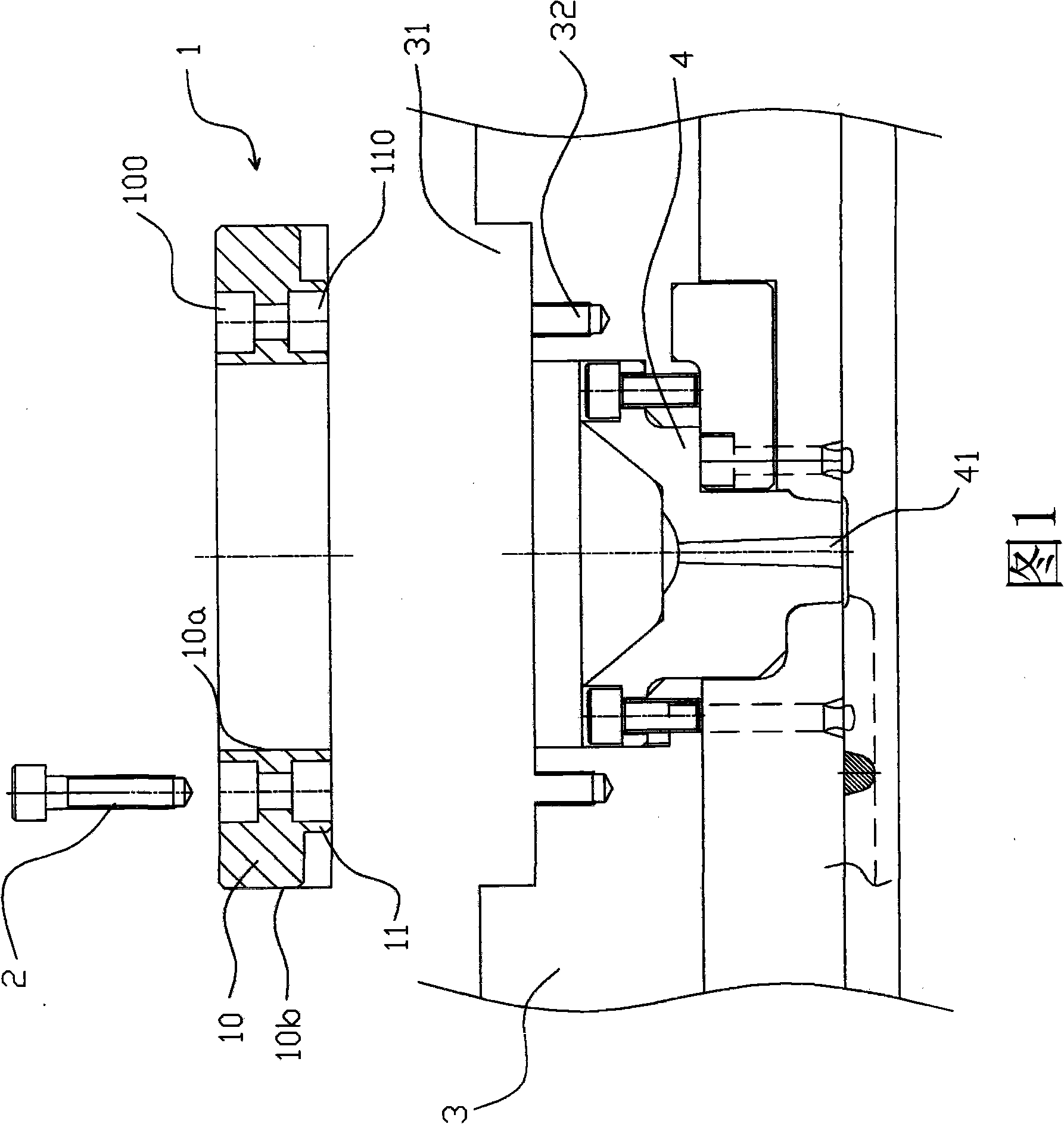

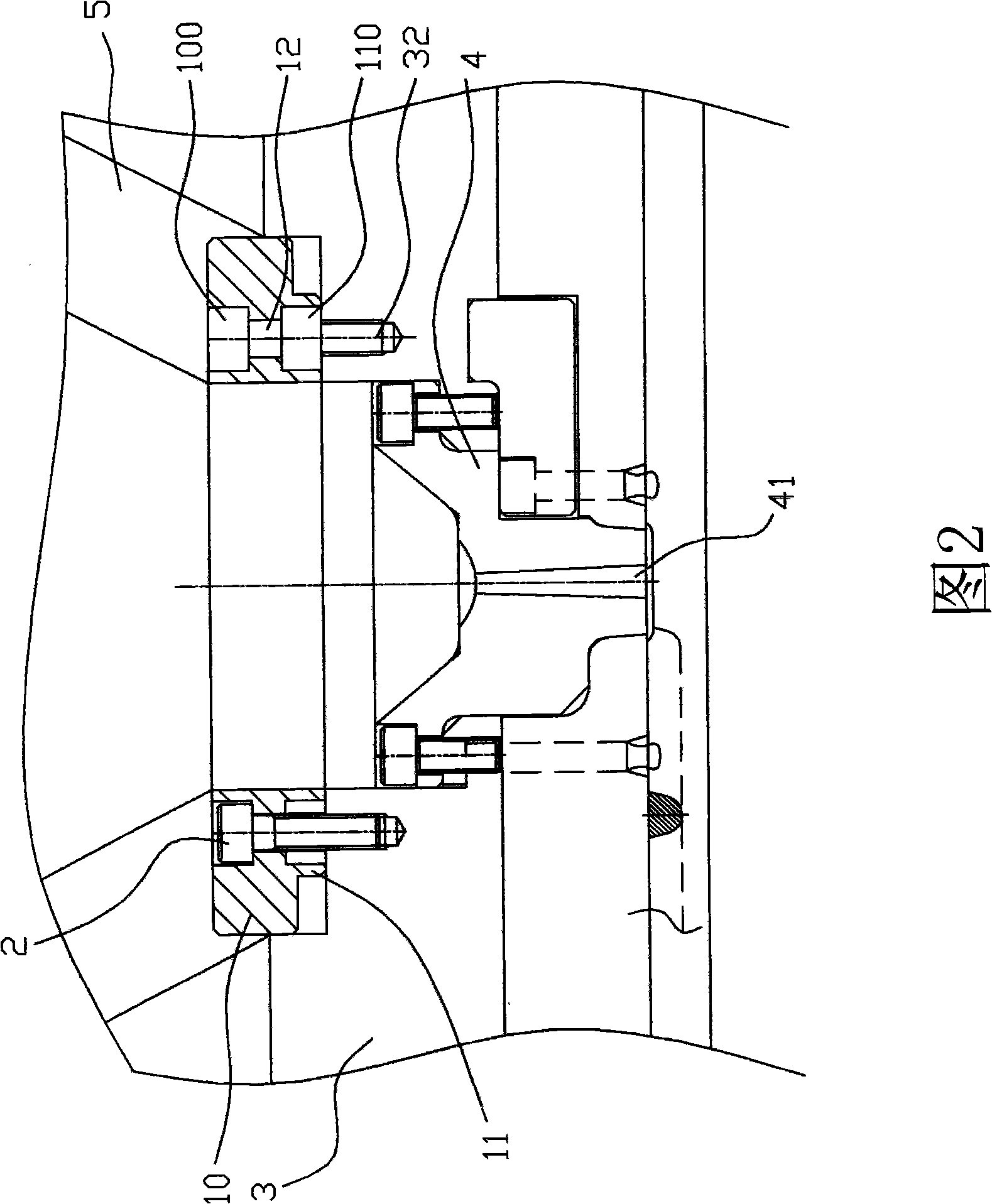

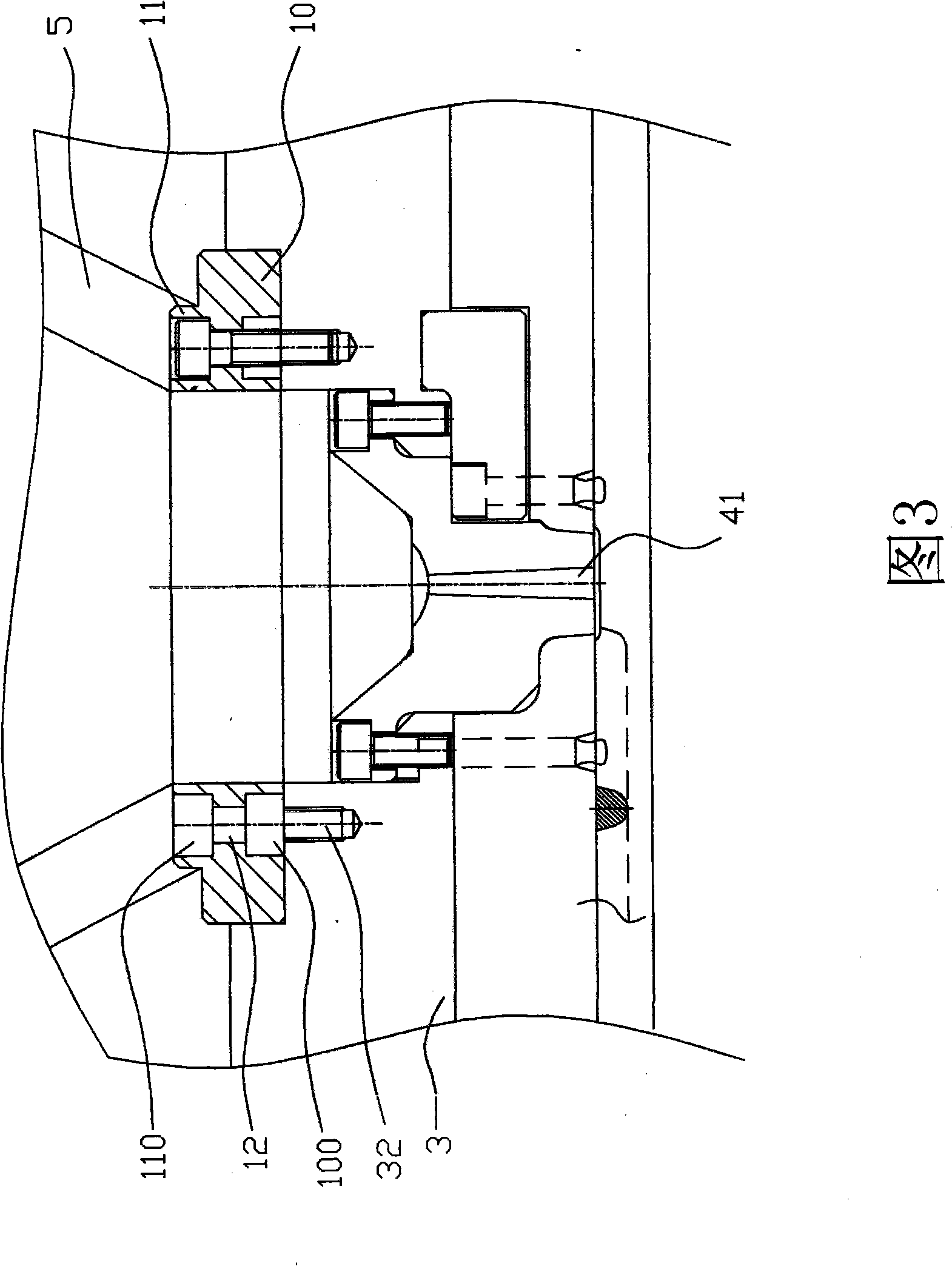

[0010] As shown in Figure 1, it is a cross-sectional view of the present invention when it is separated from the fixed plate, wherein the positioning ring 1 is assembled in a fixed plate 3, and it includes an annular body 10, which includes a concentric inner circle 10a and outer circle 10b, and one side of the main body 10 protrudes along the inner circle 10a, and a protruding body 11 which is also closed and formed into a ring, and the outer diameter of the protruding body 11 is the same as the outer diameter of the main body 10 (that is, the diameter of the outer circle 10b ) inconsistent, in this embodiment, the outer diameter of the protrusion 11 is smaller than the diameter of the outer circle 10b, and the protrusion 11 is provided with at least two first nut holes 110 that are recessed toward the body 10, and the first nut The bottom of the cap hole 110 runs through the body 110 to form at least two holes 12, and at least two second nut holes 100 symmetrical to the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com