Color-coded shrink wrapped closure system

a color-coded, closure system technology, applied in the direction of caps, liquid handling, applications, etc., can solve the problems of not being able to easily remove the cap, the tab on the push-on cap of the 5-gallon container is not easily pulled off, and the combination does have its limitations, so as to reduce the storage space, less space, and the effect of significant storage spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

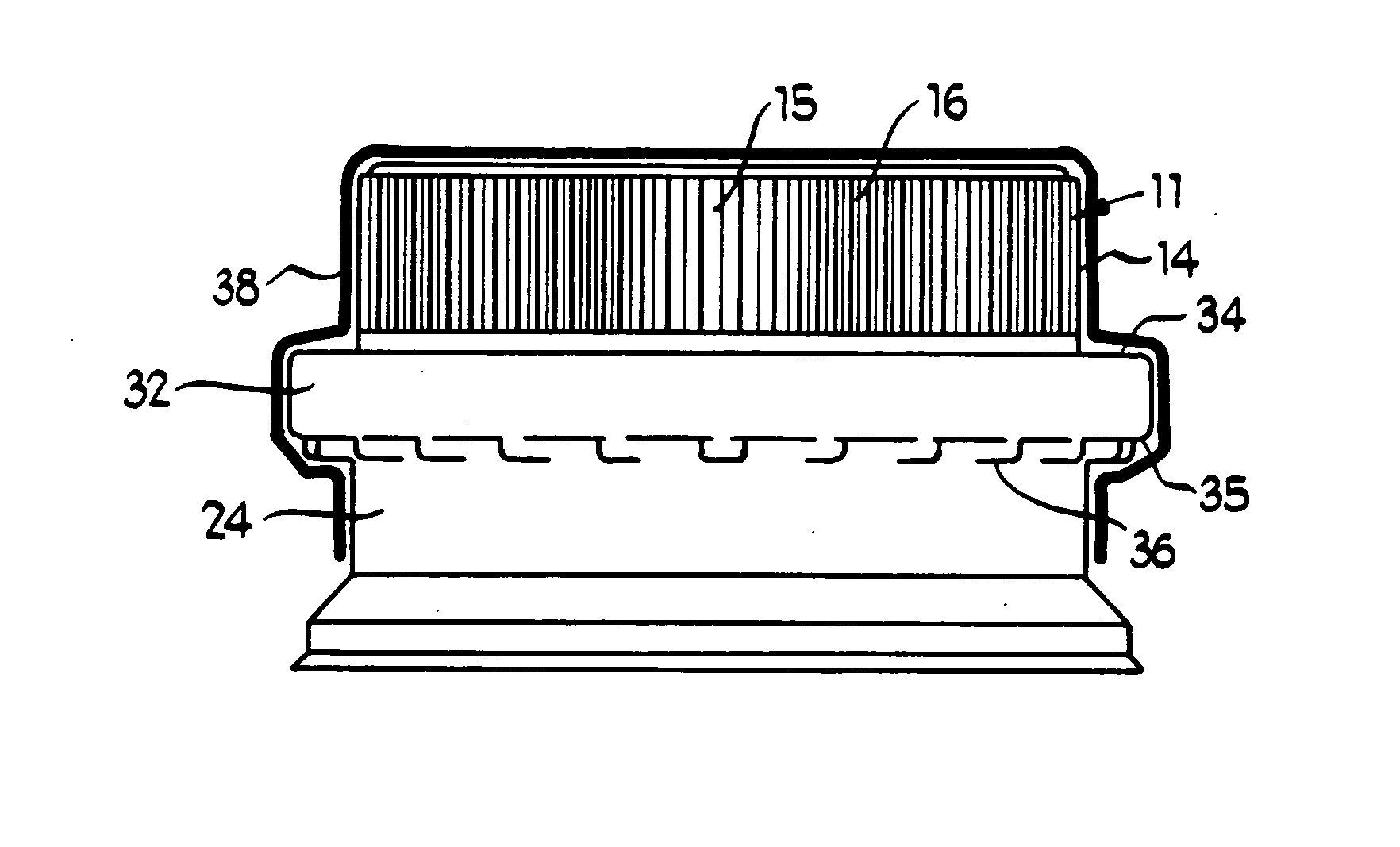

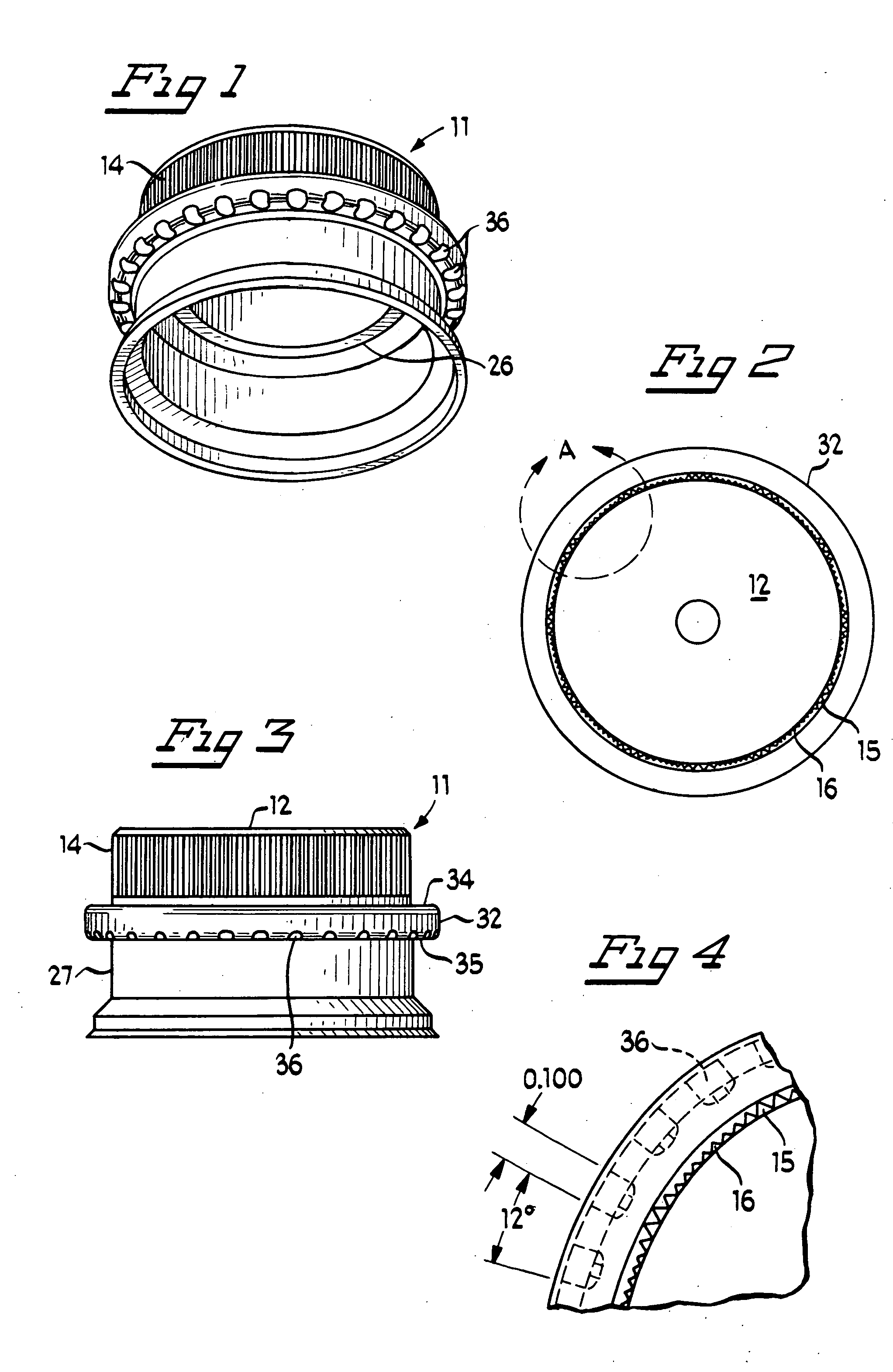

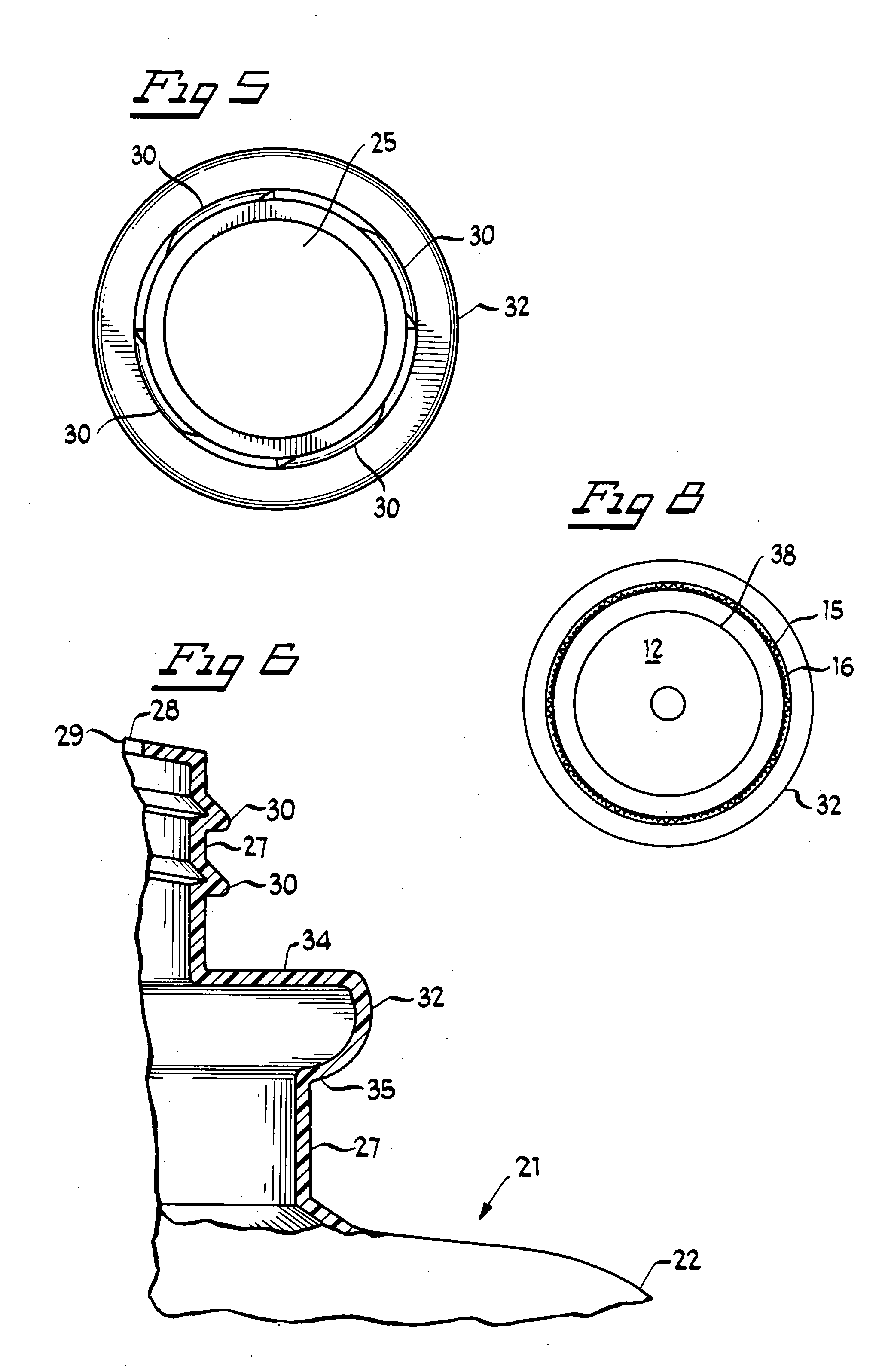

[0046]FIGS. 1 and 3 generally depict the outside of a bottle cap and bottle neck of the inventions described and claimed herein. FIG. 1 depicts the cap and neck combination in a perspective view, while FIG. 2 illustrates a top view of a cap 11 and bottle neck 24 of the inventions described and claimed herein before a shrink wrap seal is placed on the bottle cap and neck. The cap 11 is comprised of a circular cover 12 and a depending skirt 14 with alternating high and low knurls 15 and 16, respectively, formed on the outside surface thereof (as shown more clearly in FIG. 4). Four distinct threads 26 are formed on the inside surface of the skirt 14.

[0047] Referring now to FIGS. 5 and 6 there is shown a bottle, indicated generally at 21, upon which the bottle cap 11 of the inventions described and claimed herein may be installed. The bottle 21 includes a body 22 and a cylindrical bottle neck 24 which is integral with the body 22. The bottle neck 24 has an upper opening 25 and an upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com