Suction port assembly of vacuum cleaner

A technology for vacuum cleaners and vacuum cleaners, applied in the directions of vacuum cleaners, suction nozzles, cleaning equipment, etc., can solve problems such as hindering the freedom of vacuum cleaners, inconvenience, complex structure, etc., achieve simple and fast switching, and eliminate the need for switching and separating flow channels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Matters such as detailed structures and elements defined in the description are provided to assist in a comprehensive understanding of the embodiments of the present invention. Accordingly, those skilled in the art will appreciate that changes may be made in this embodiment without departing from the scope and spirit of the invention. Also, descriptions of well-known functions and constructions are omitted for clarity and conciseness.

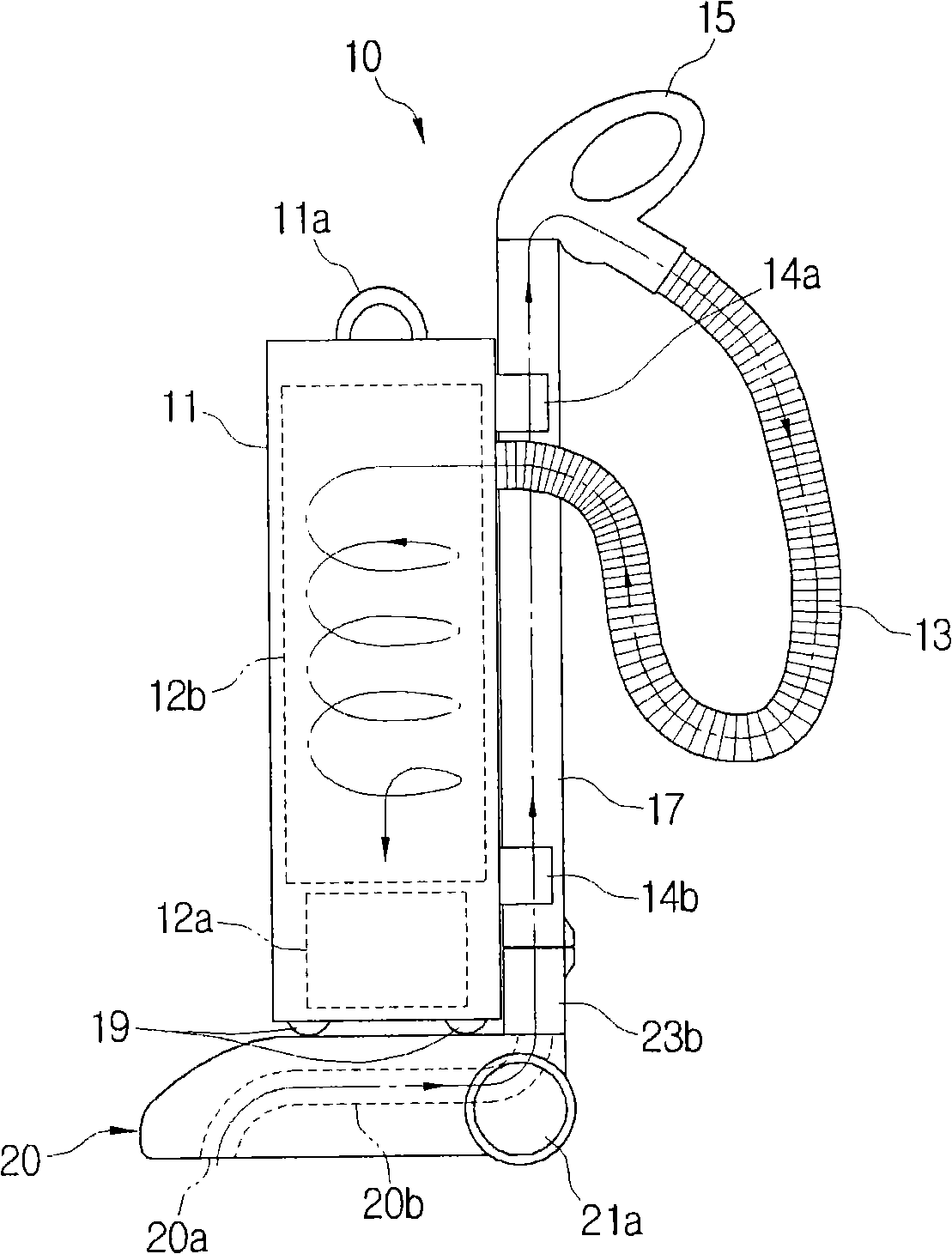

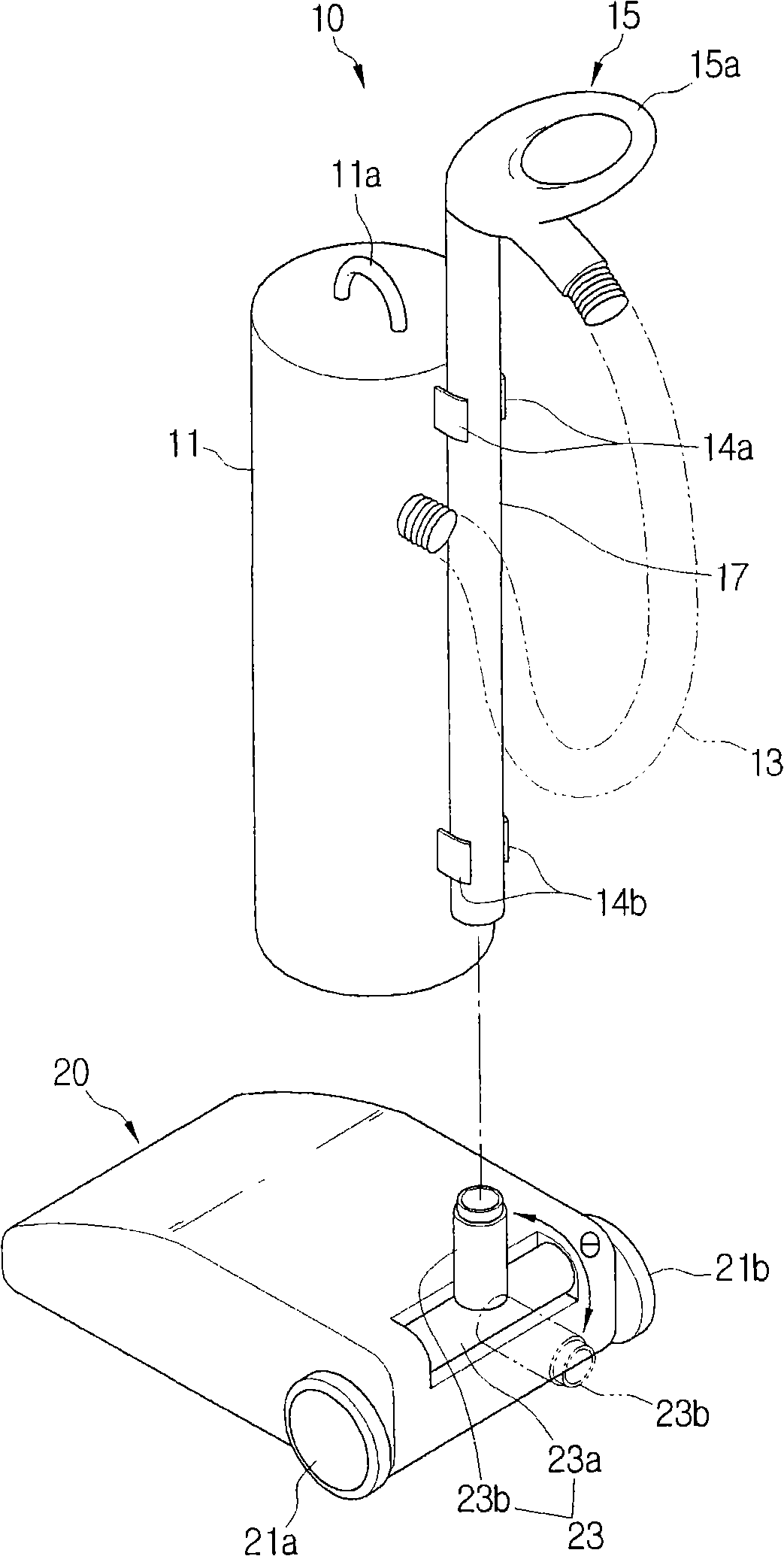

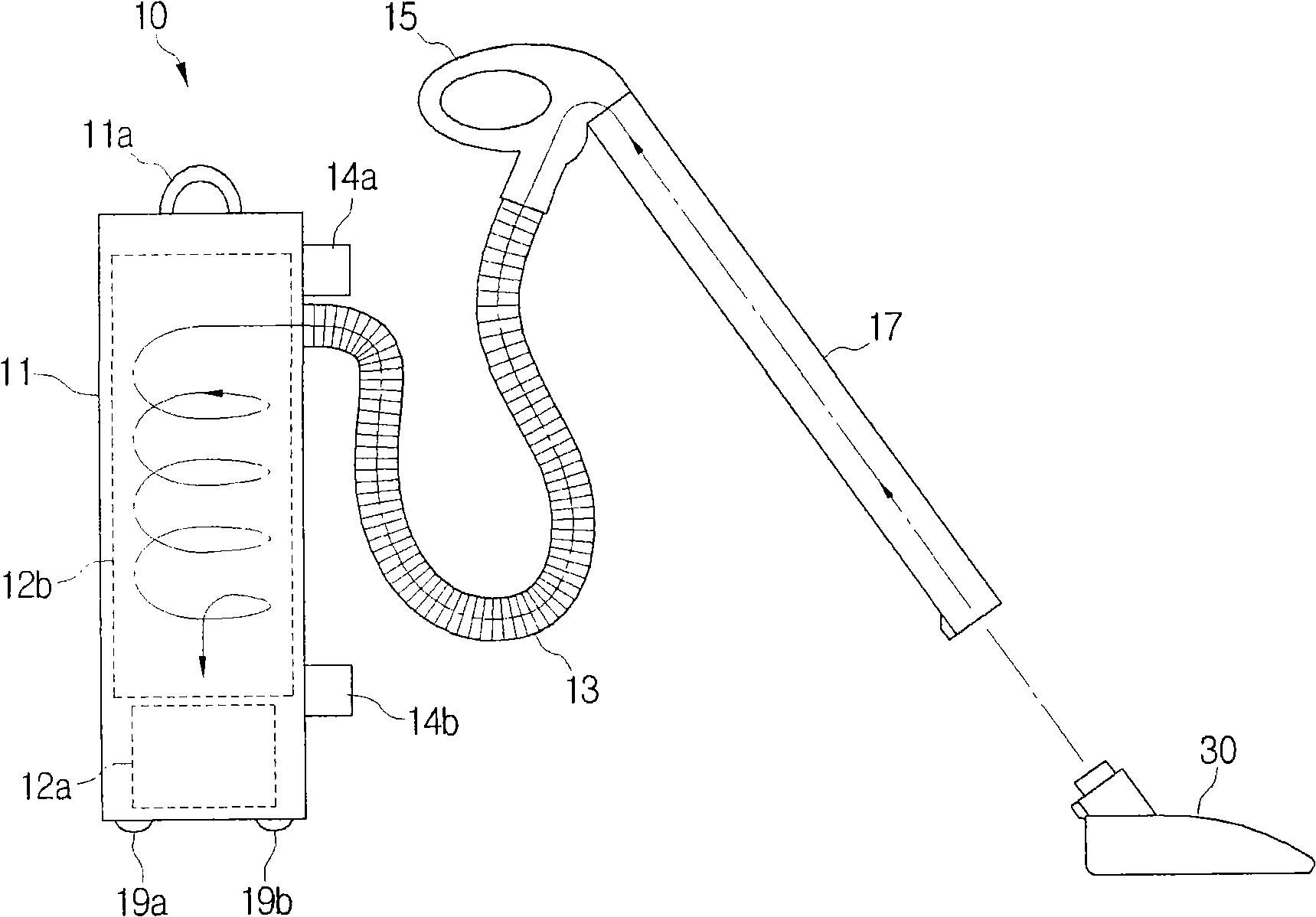

[0037] refer to figure 1 with 2 , the vacuum cleaner according to the first exemplary embodiment of the present invention, which includes a cleaning unit 10 and a suction port assembly 20 . The cleaning unit 10 is detachable from the suction port assembly 20 and used separately.

[0038] The cleaning unit 10 may include a cleaner body 11 , a hose 13 , an operating handle assembly 15 , and an extension pipe 17 .

[0039]The cleaner unit 11 may include a suction motor 12a for generating suction inside the cleaner main body 11; Separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com