Exposure apparatus of belt type workpiece and focusing regulation method thereof

A focus adjustment and exposure device technology, which is applied in photolithography process exposure devices, microlithography exposure equipment, optics, etc., can solve problems such as unestablished, and achieve the effects of preventing productivity reduction and correcting changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

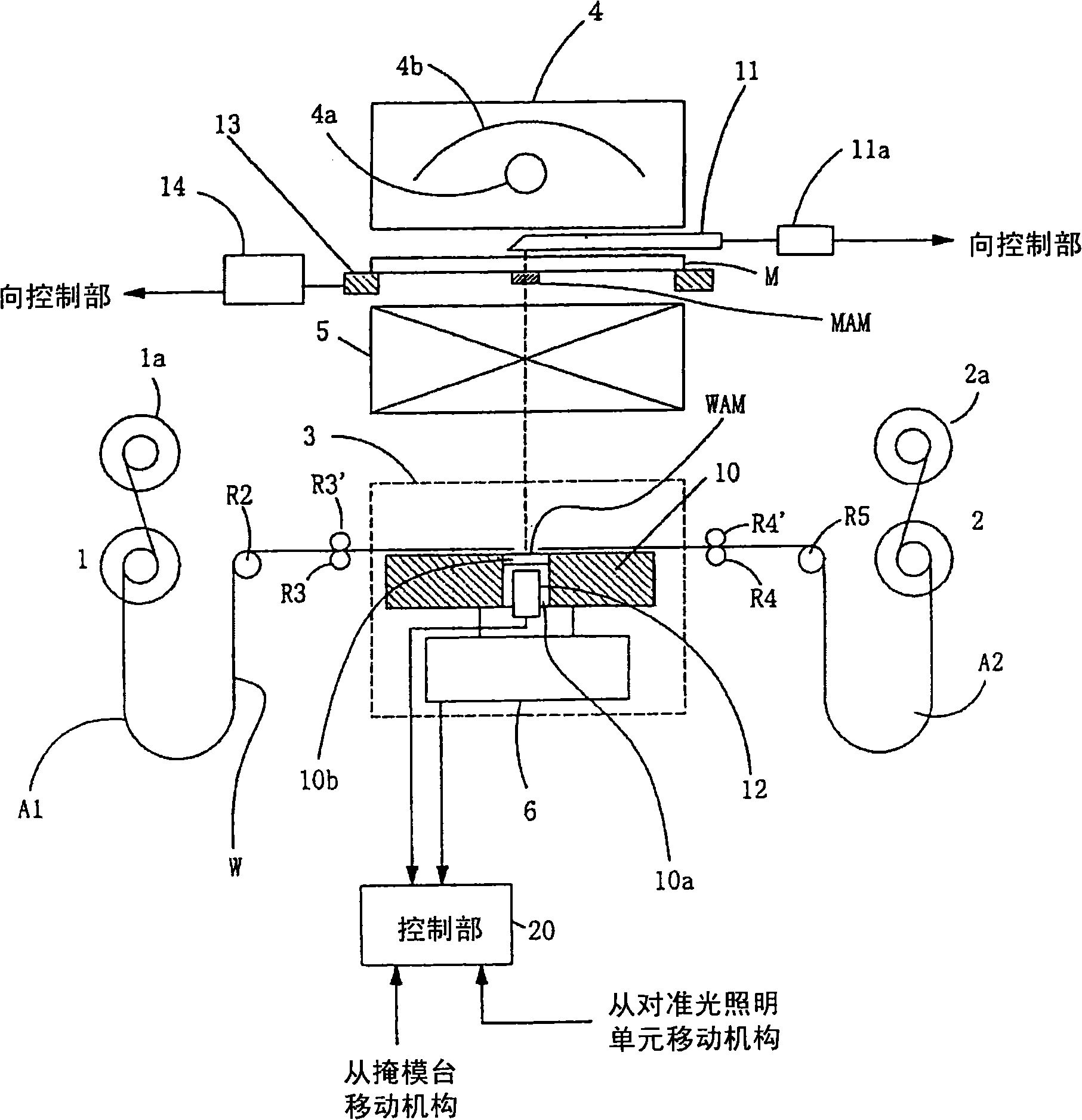

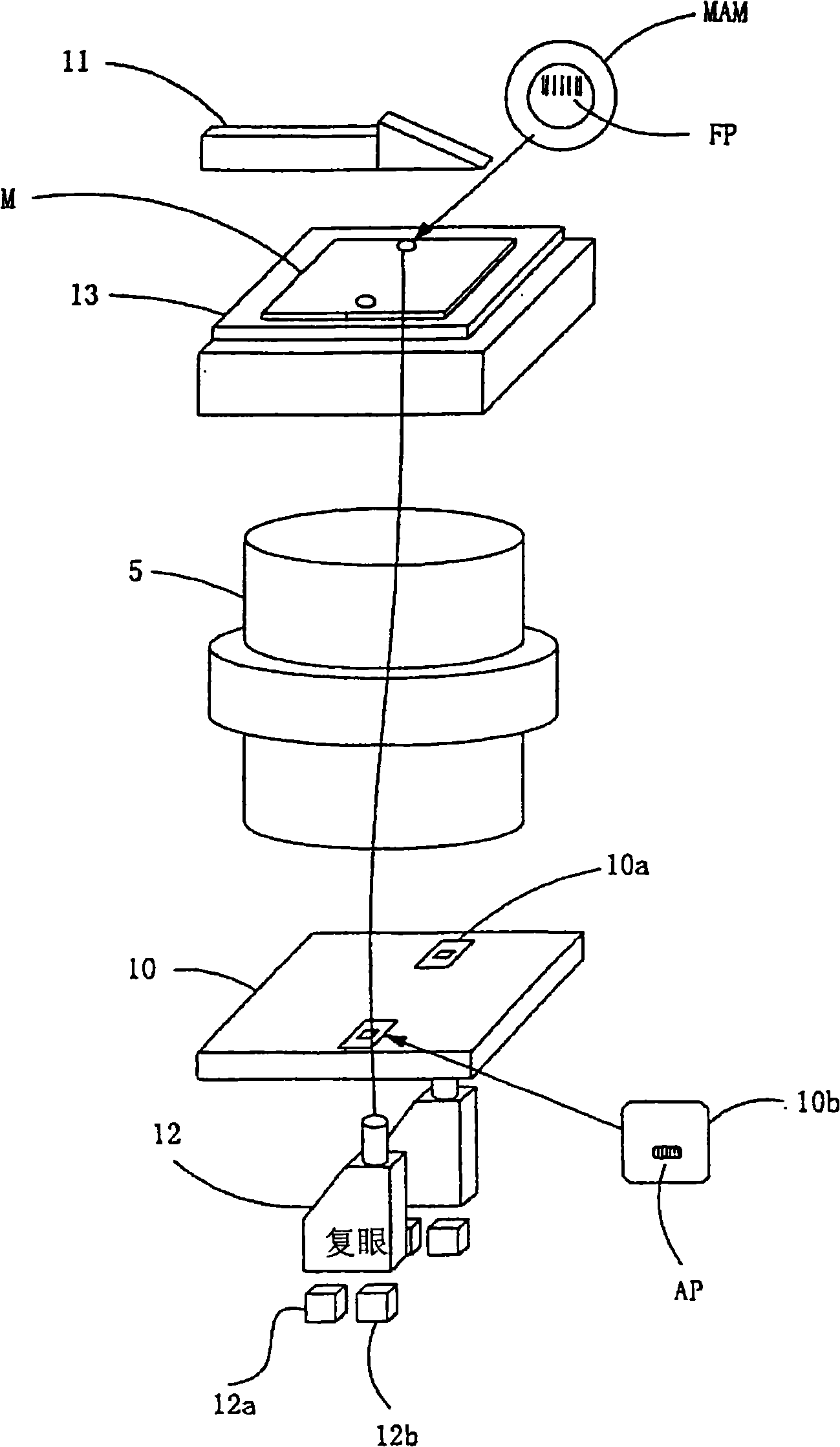

[0078] exist figure 1 , figure 2 The device configuration of the embodiment of the present invention is shown. figure 1 The overall configuration of the exposure apparatus for a belt-shaped workpiece according to this embodiment is shown, figure 2 expressed in figure 1 In the shown apparatus, a drawing showing parts of an alignment light illumination means, a mask stage, a projection lens, a work stage, and an alignment microscope is extracted.

[0079] exist figure 1 , figure 2 In this case, the mask stage 13 is moved at least in the Z direction (optical axis direction, vertical direction in the drawing) by the mask stage moving mechanism 14 .

[0080] The workpiece table 10 is also moved in the optical axis direction (Z direction, vertical direction in the drawing) by the workpiece table moving mechanism 6 .

[0081] The mask stage 13 and the work stage 10 move with the position of the focal length (design value) of the projection lens 5 as the origin position i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap