Fire extinguishing gas spray device

A gas ejector and gas technology, which is applied in fire rescue and other directions, can solve the problems of inability to quickly extinguish the fire, time-consuming, and missed fire extinguishing, etc., and achieve the effect of easy and rapid operation, initial fire extinguishing, and effective utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

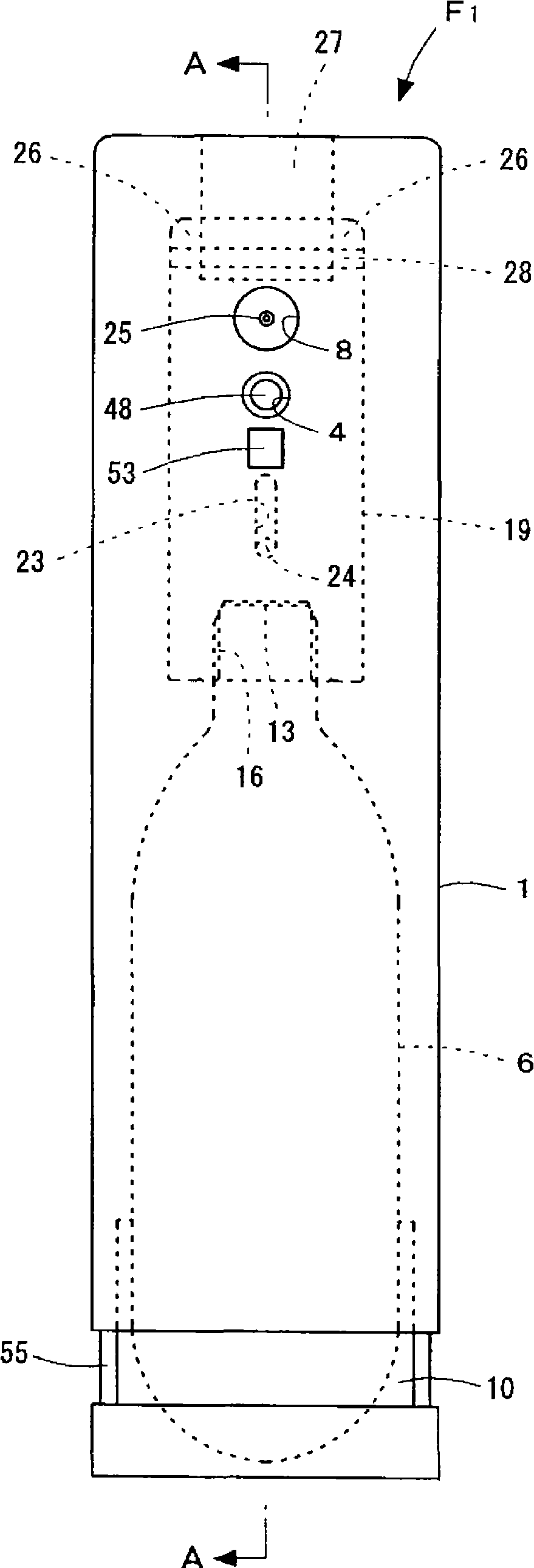

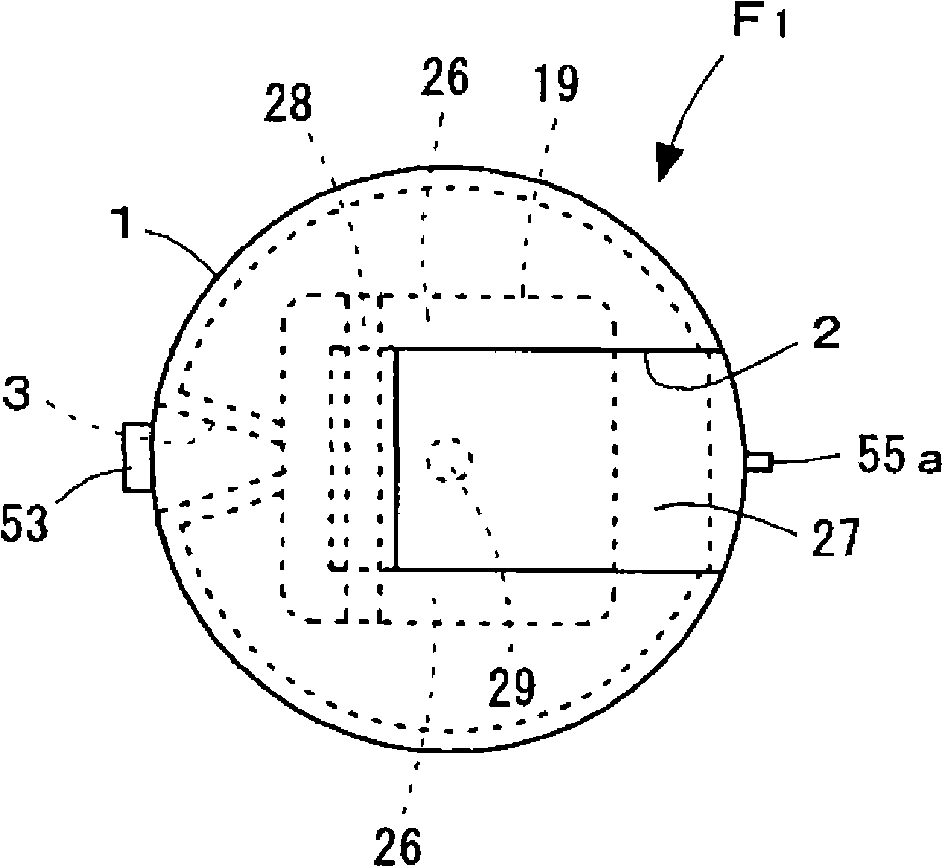

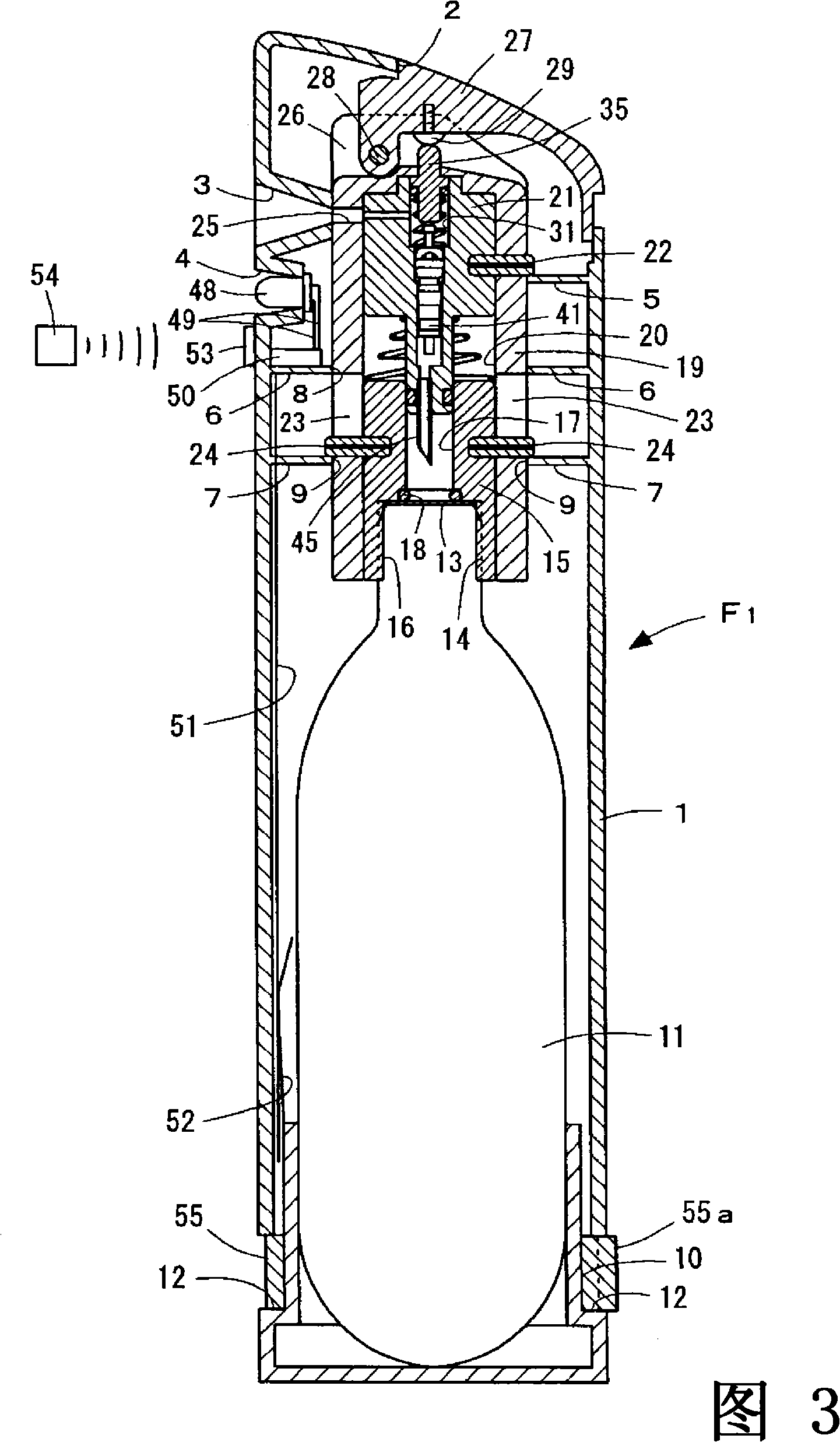

[0105] Next, apply the present invention to a household or vehicle-mounted fire extinguishing gas injector using a cartridge-type gas cylinder in the drawings, that is, a simple fire extinguisher F that is small, light, and can be carried with one hand. 1 The implementation of the description will be given in Figure 1 to Figure 6 Among them, element number 1 is a substantially hollow cylindrical upper casing made of synthetic resin, which is constructed by joining a pair of split casings that divide the center of the discharge hole described below into two in the axial direction. The lower end of the upper housing is open, the upper end is closed, and the upper end is formed in a generally tapered shape inclined backward, and an opening 2 is formed in the center of the upper end.

[0106] An operation lever described below is attached to the above-mentioned opening 2, and a discharge hole 3 is formed on the upper peripheral surface of the front portion facing the nozzle descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com