Electric connector automatic separating apparatus

An electrical connector, automatic separation technology, applied in the parts of the connection device, connection, coupling device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

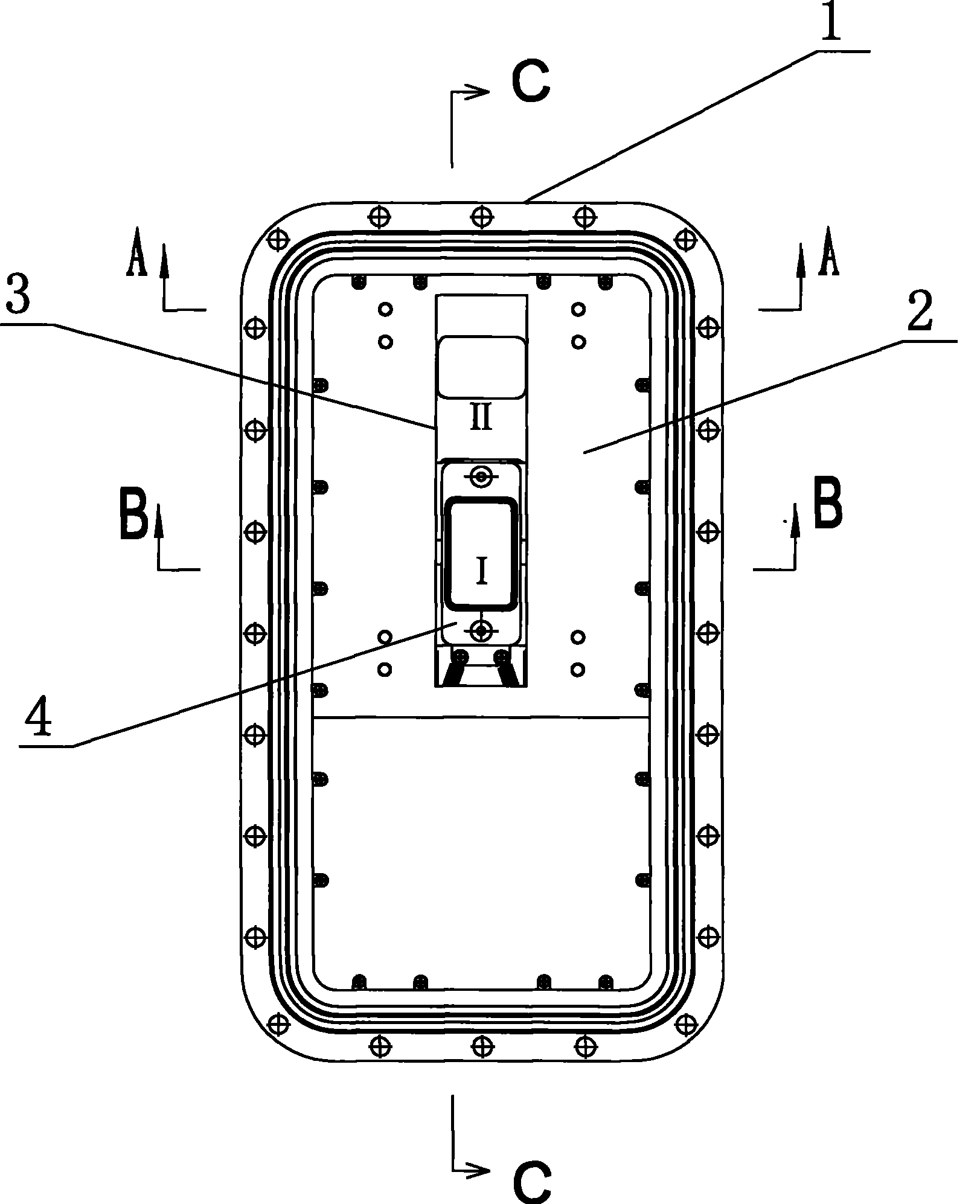

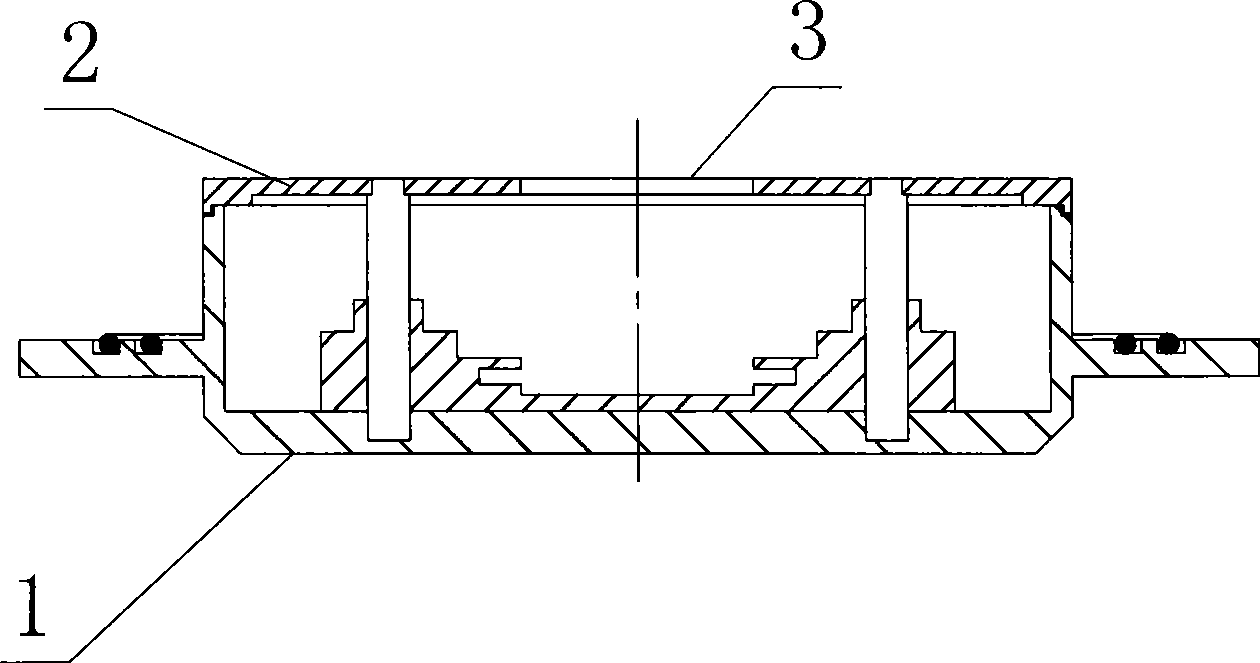

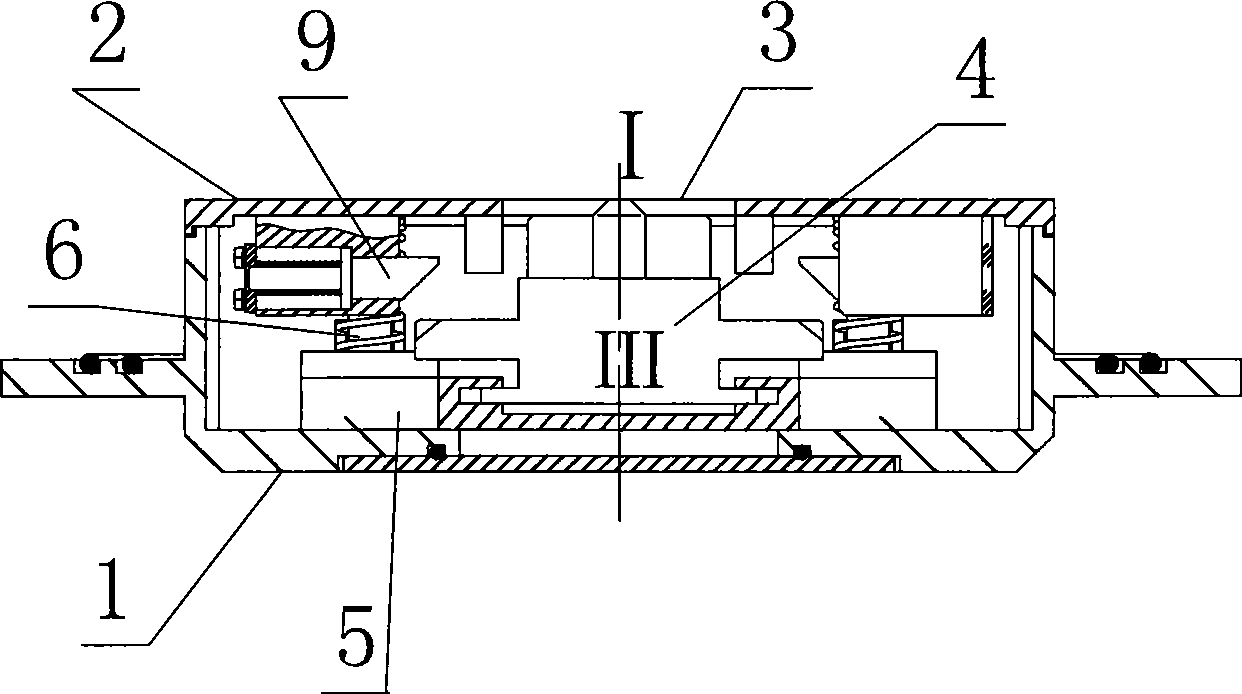

[0022] Such as Figure 1 to Figure 7 As shown, an automatic separation device for electrical connectors of the present invention includes a housing 1, and the panel 2 of the housing 1 is provided with a capacitive connector. The plug-in port 3 is moved in the vertical direction at the same time, and the plug-in port 3 has an insertion position I and a separation position II. The insertion position I corresponds to the connector seat 4 and moves out of the plug-in port 3. When the connector is plugged in The separation position II corresponds to the position where the connector seat 4 is submerged in the insertion port 3, and the fully submerged position of the connector seat 4 in the direction of unplugging and insertion corresponding to the insertion position I is the return position III. The guide rail 5 is movably assembled in the body 1 through the guide column 6 guided along the direction of connector plugging and unplugging. Correspondingly, the connector seat 4 is mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com